Method for Predicting Reaction Performance in Solid Fuel Chemical Looping Process Based on GBRT

A technology of solid fuel and reaction performance, which is applied in chemical analysis by combustion, machine learning, instruments, etc. It can solve problems such as difficult to obtain, high data, complex internal logic between data, etc., and achieve the effect of saving time and continuous feature data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

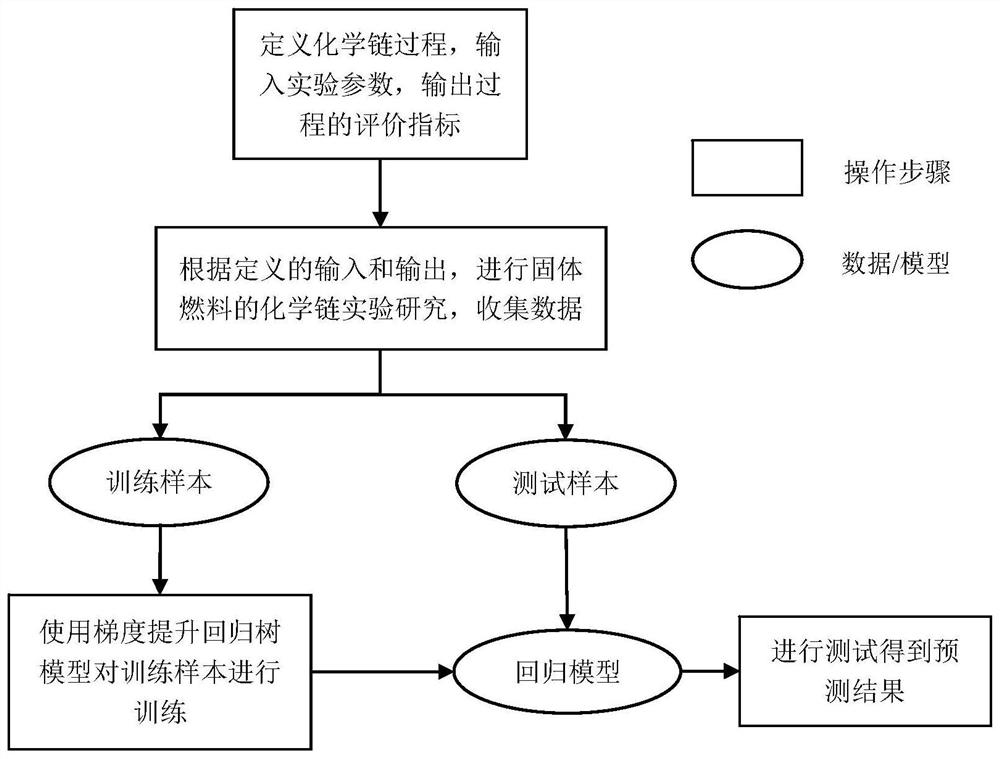

[0037] The content of the present invention will be further clarified below in conjunction with the accompanying drawings and specific embodiments, but the embodiments are only used to illustrate the present invention and are not intended to limit the protection scope of the present invention. The concrete steps of embodiment are as figure 1 shown.

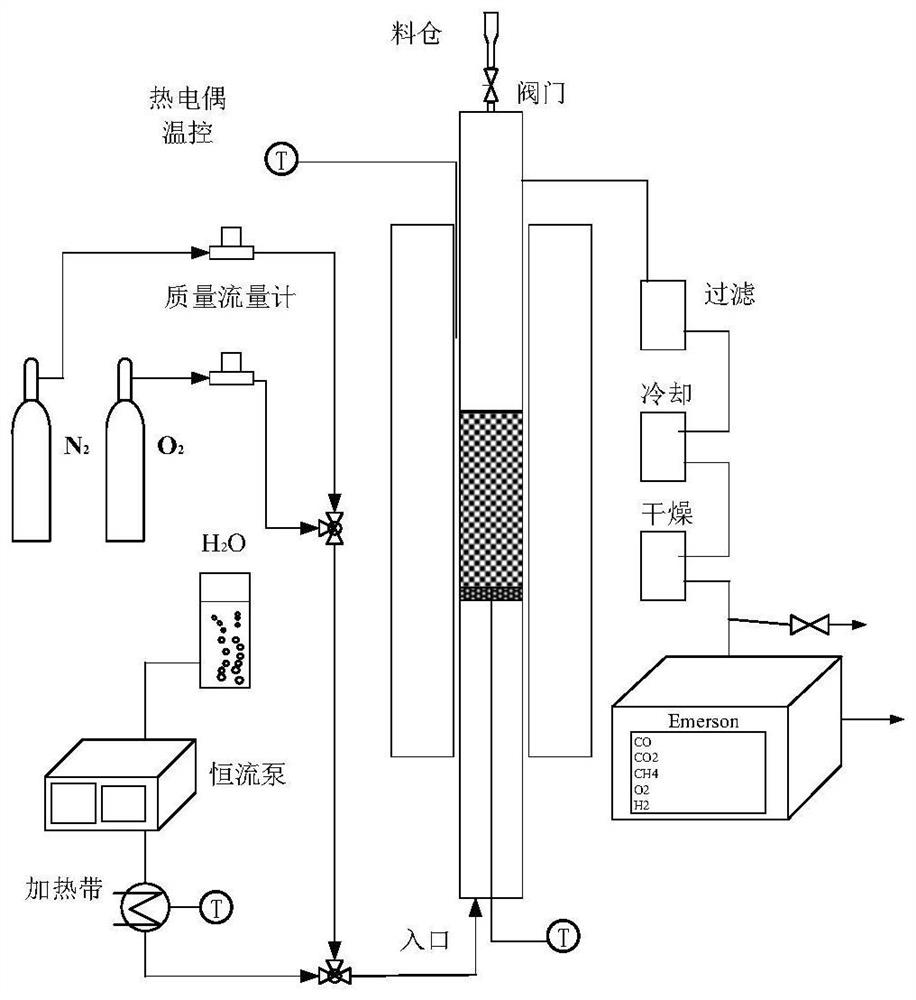

[0038] First, the solid fuel is selected as petroleum coke and anthracite, and the oxygen carrier is iron ore. The solid fuel in this embodiment can be selected from one or more of coal (including lignite, bituminous coal, anthracite), biomass, and petroleum coke. A mixed fuel; the oxygen carrier can be iron-based, nickel-based, copper-based or multi-metal oxygen carrier, as well as natural oxygen carrier. Experimental studies were carried out in a single-batch fed small fluidized bed. The reaction temperature, water vapor flow rate, O / C (the ratio of the molar amount of oxygen in the oxygen carrier to the molar amount of carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com