Method and device for measuring delivery speed of continuous casting pieces in real time

A technology of real-time measurement and speed, applied in the direction of measuring devices, radio wave measurement systems, using re-radiation, etc., can solve the problems of heavy calculation workload and small coverage of single camera, and achieve high positioning accuracy and wide coverage frequency range , Strong anti-multipath effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

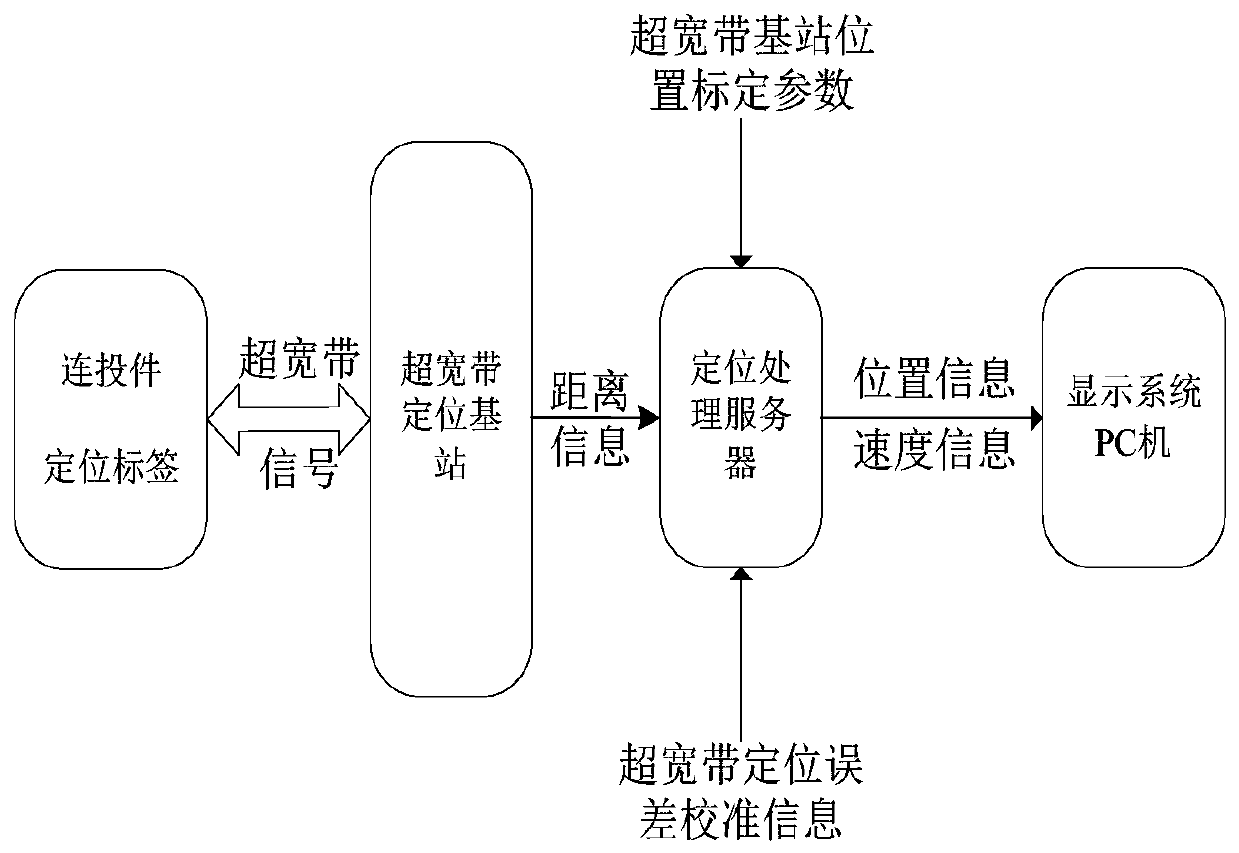

[0048] figure 1 It is a schematic flow chart of the method for real-time measurement of the out-of-chamber speed of continuous casting pieces according to an embodiment of the present invention.

[0049] Such as figure 1 As shown, the method may include the following steps:

[0050] Calibrate the spatial position and positioning error in the body coordinate system of the UWB base station;

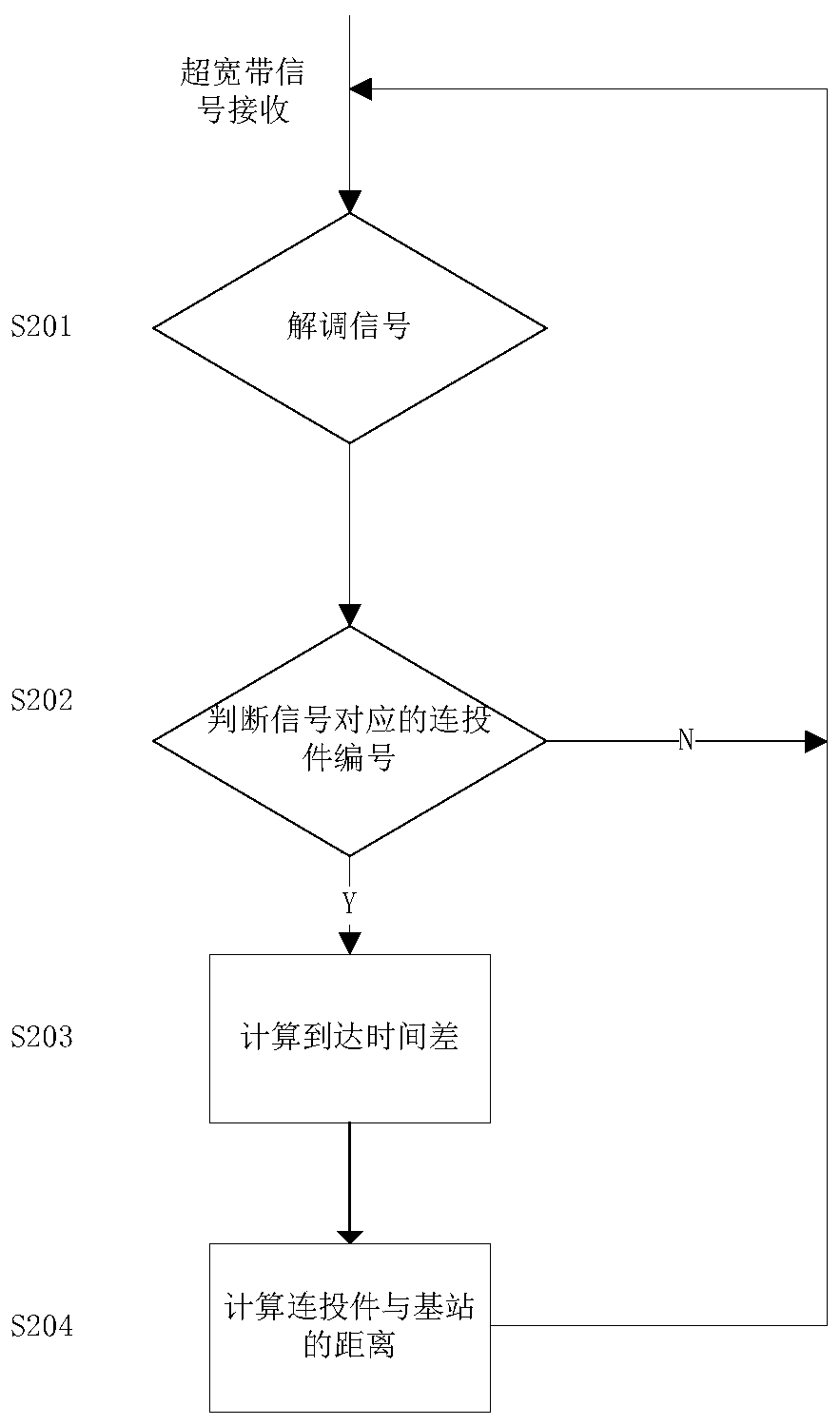

[0051] The ultra-wideband base station receives the ultra-wideband signal fed back by the positioning tag on the continuous delivery piece in real time, and calculates the real-time distance between the continuous delivery piece and the positioning base station;

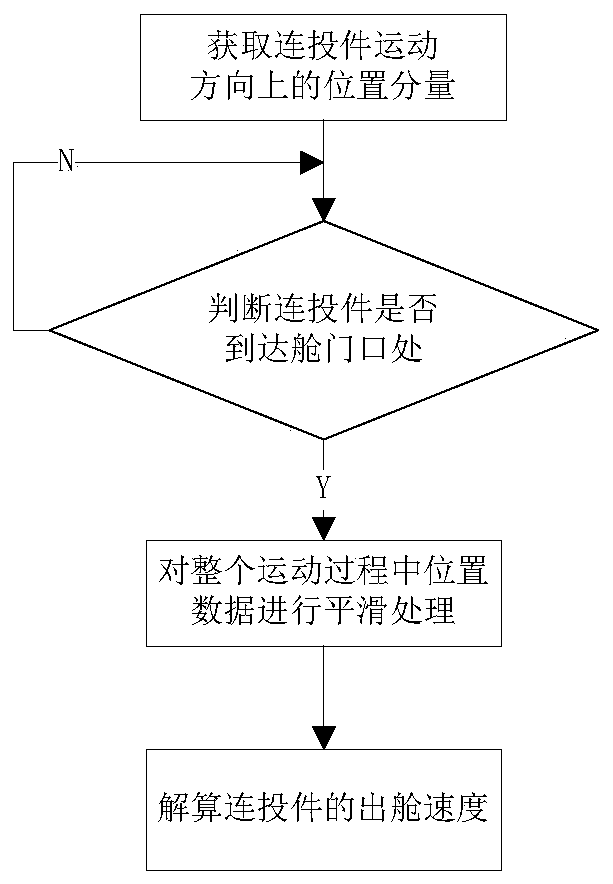

[0052] The positioning server obtains the distance information of the positioning base station, and according to the calibration and calibration information, obtains the position component of the continuous casting part in the moving direction;

[0053] Smoothing the position component and calculating the velocity;

[0054] Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com