Coating process of multi-color plate

A coating process and multi-color technology, which is applied to the surface coating liquid device, coating, pre-treatment surface, etc., can solve the problems of inability to meet diversified customer needs, single color, short service life of products, etc. , to achieve the effect of improving artistic sense and applicability, reducing spillage and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

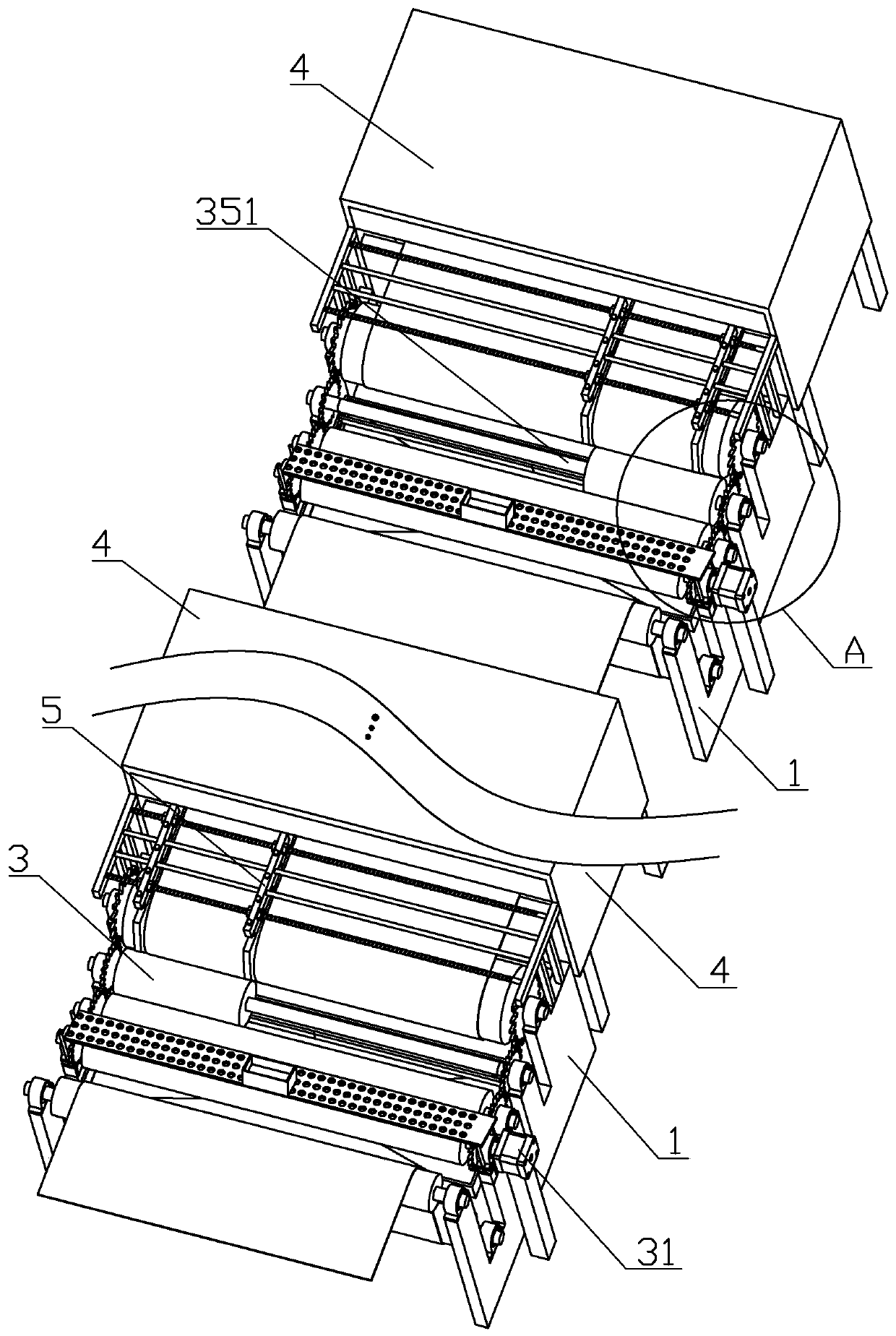

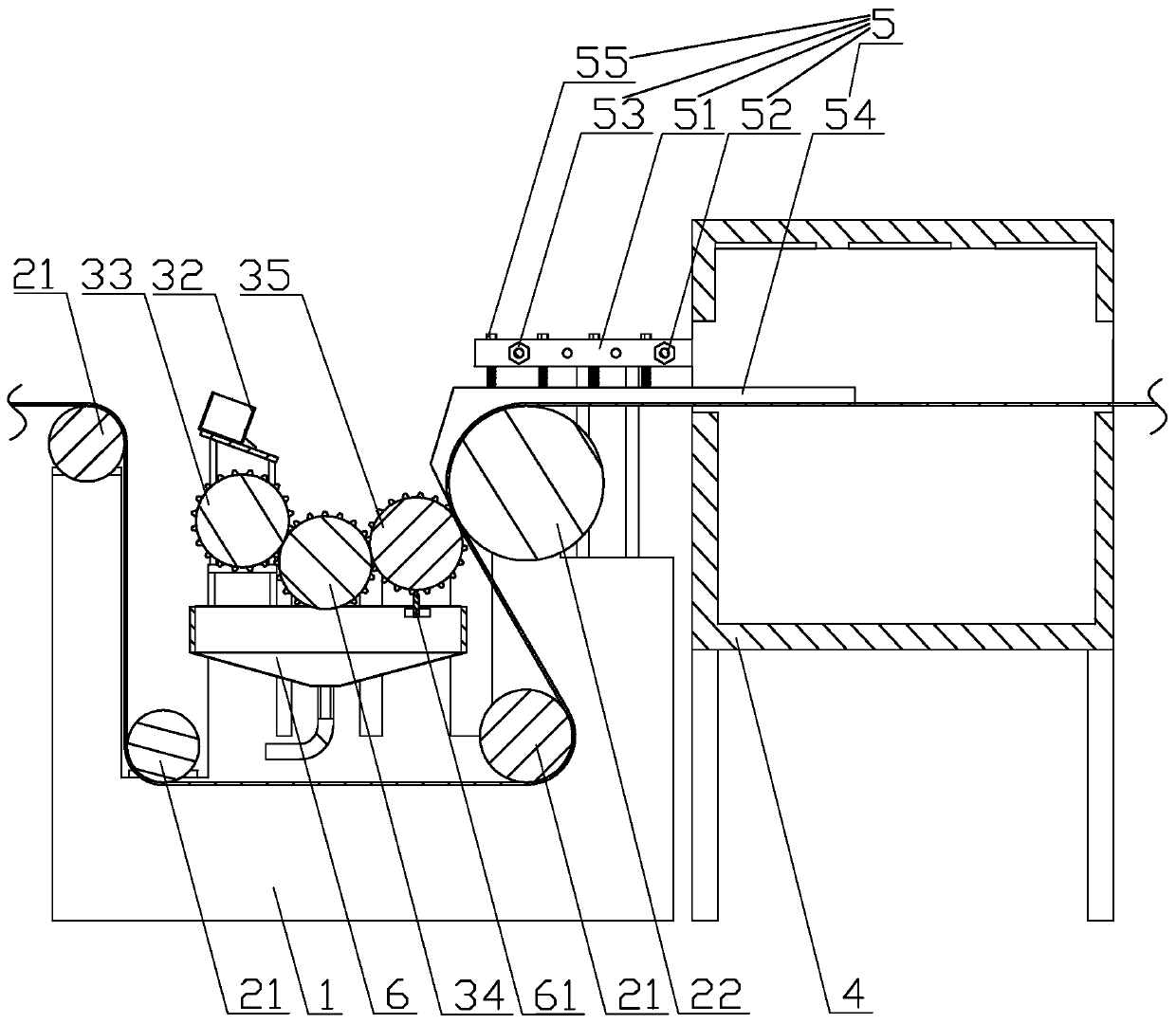

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

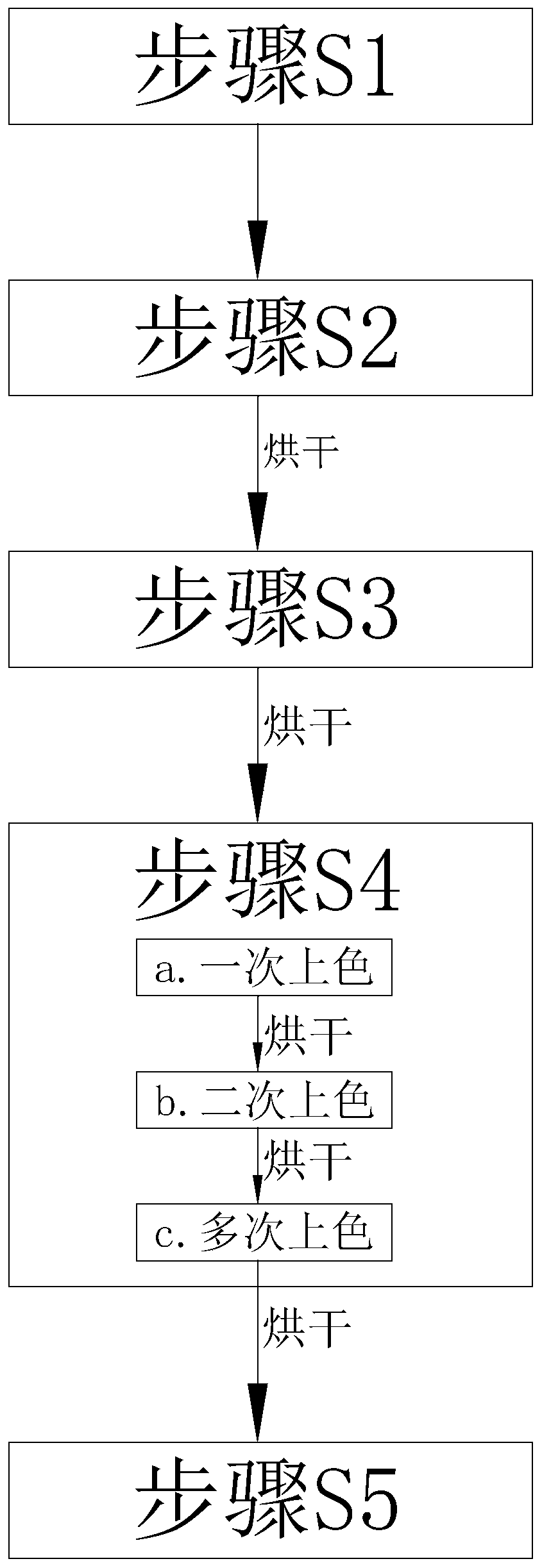

[0047] Such as figure 1 , figure 2 Shown, a kind of multi-color plate coating process comprises the following steps:

[0048] Step S1. Pre-treatment: Unwind the rolled base material, wash and dry;

[0049] Step S2. Roller coating of the primer layer: transfer the color plate to the primer roller coater for roller coating of the primer layer, and dry after the roller coating is completed;

[0050] Step S3. Roller coating intermediate coating: transfer the color plate coated with the primer layer to the intermediate coating roller coater for roller coating of the intermediate coating, and dry after the roller coating is completed;

[0051] Step S4. Roller coating of the topcoat layer: the color plate after the intermediate coating is applied is transferred to the topcoat roller coating unit for roller coating of the multi-color topcoat layer. The topcoat ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com