Light flexible wing with variable-camber trailing edge

A flexible, trailing edge technology used in the aerospace field to improve overall aerodynamic performance, increase flight time and range, and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in conjunction with accompanying drawing.

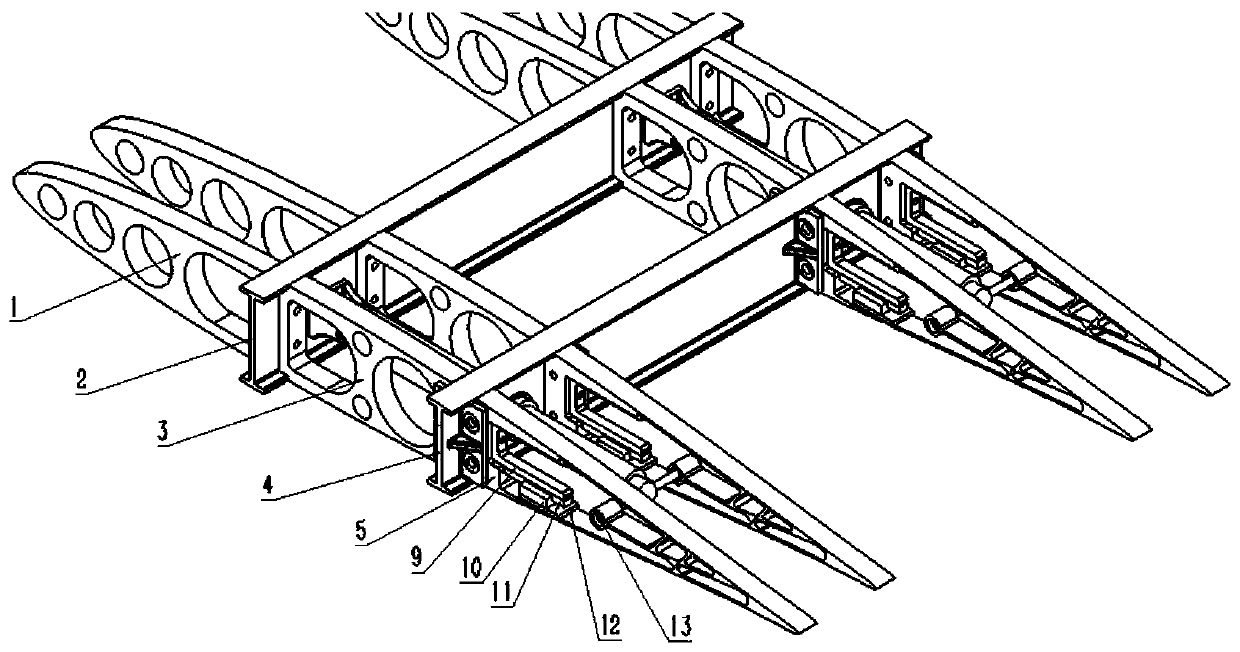

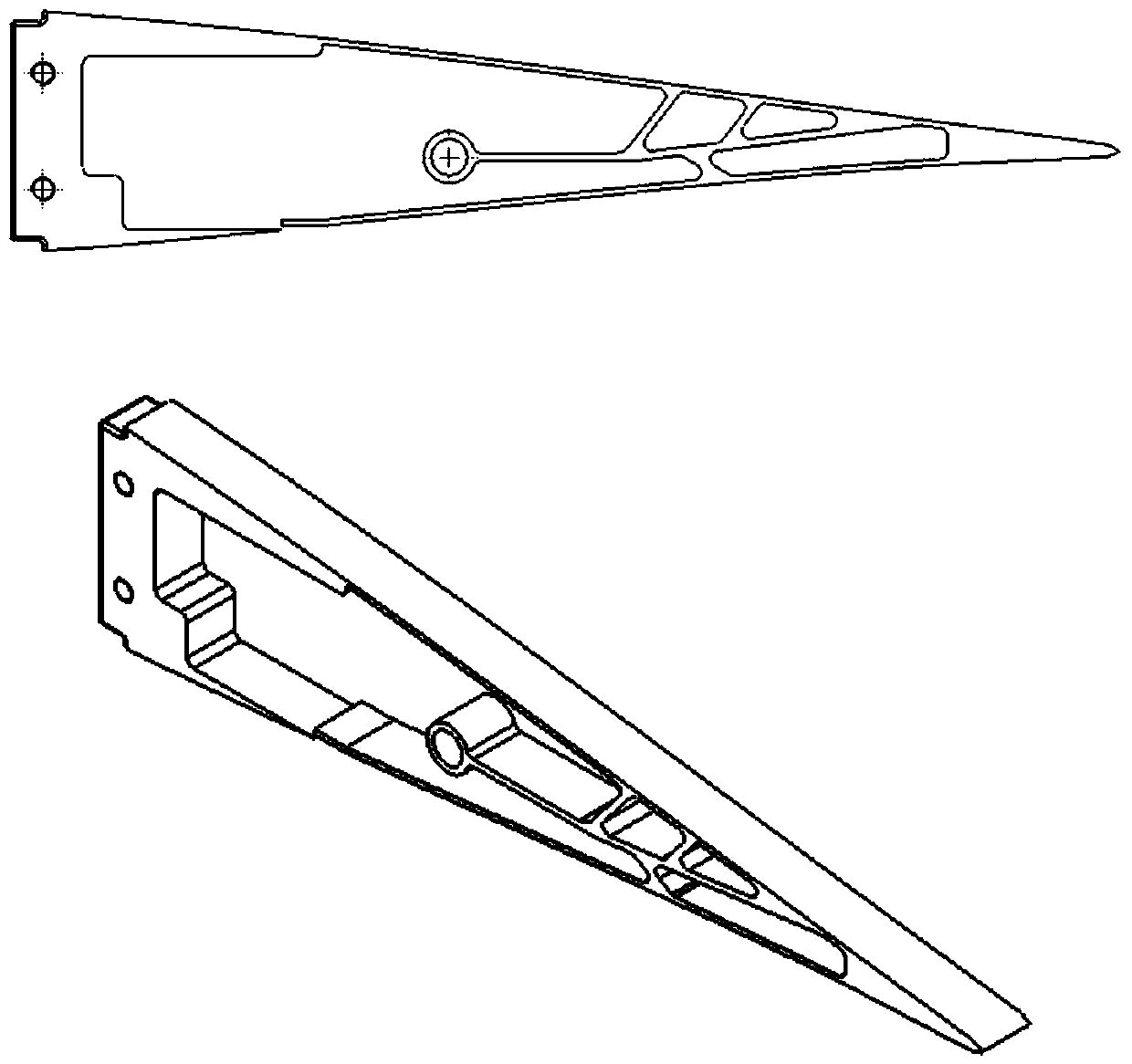

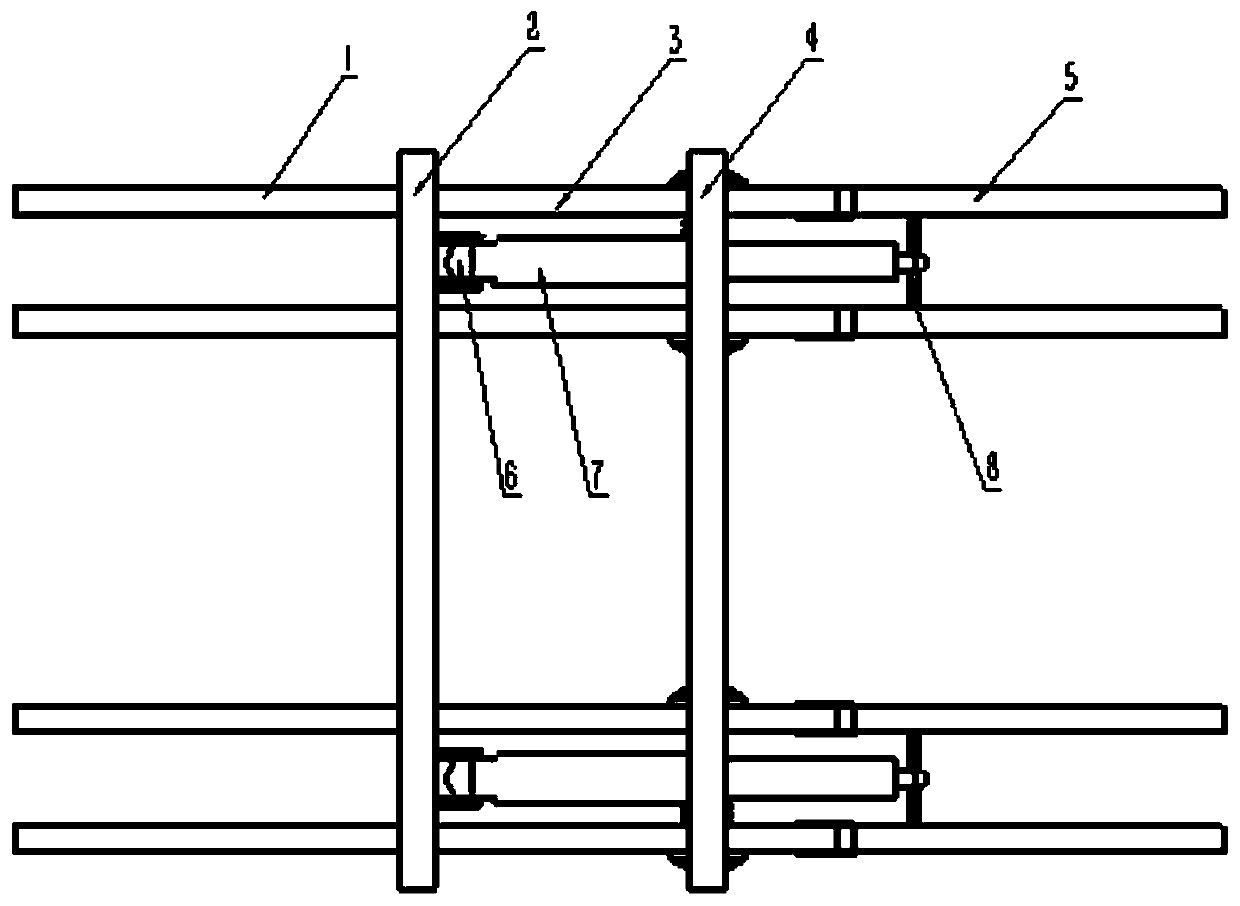

[0033] Such as Figure 1-5 As shown, the present invention provides a lightweight flexible variable trailing edge camber wing, comprising a leading edge rib 1, a front spar 2, a middle rib 3, a rear spar 4, a flexible trailing edge 5, and a motor support 6. Linear motor 7, motor and flexible trailing edge connecting rod 8, flexible trailing edge and guide rail connecting plate 9, slider 10, guide rail 11, slider and flexible trailing edge connecting plate 12, pull ring 13, skin;

[0034] The front rib 1 and the middle rib 3 are connected by the front spar 2 and fixed together; the middle rib 3 and the flexible trailing edge 5 are connected by the rear spar 4 and fixed together; the front end of the linear motor 7 is connected by the motor The support 6 is fixed on the front spar 2, and the rear end passes through the rear spar 4 and is connected to the pull ring 13 through the flexible rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com