Graphite negative-pressure feeding device

A feeding device and negative pressure technology, applied in the field of graphite negative pressure feeding device, can solve the problems of increase of finished products, energy waste, intermittent feeding, etc., and achieve the effect of stable and continuous feeding, easy smooth transportation, and reduced blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

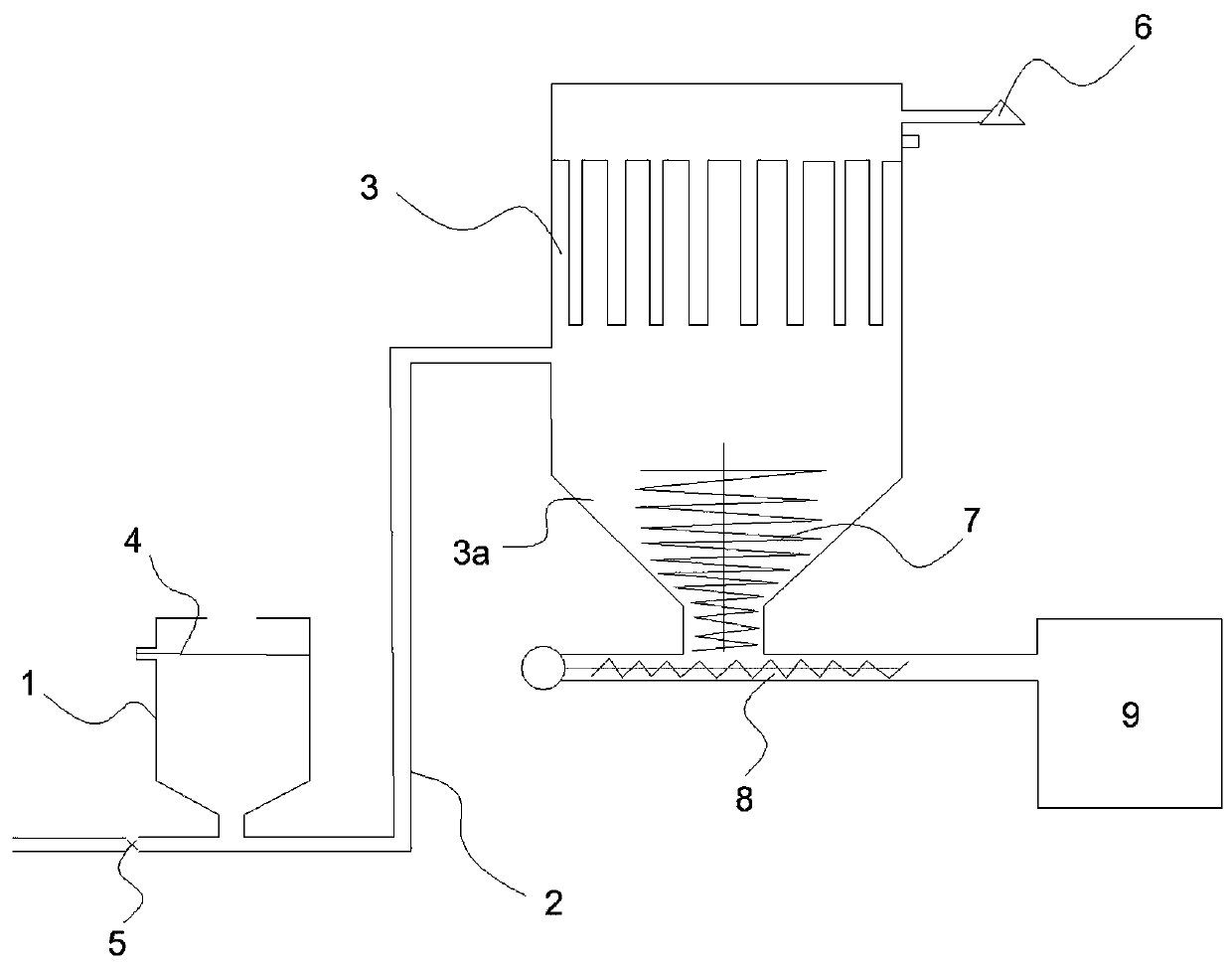

[0012] Such as figure 1 As shown, the present invention provides a graphite negative pressure feeding device, comprising a feed bin 1, a feed air duct 2 and a pulse type dust collector 3, the top of the feed bin 1 is provided with a sieve plate 4; It is horizontally arranged under the feeding bin 1, and the side wall of the feeding air pipe 2 is connected with the bottom of the feeding bin 1; one end of the feeding air pipe 2 is the air inlet, and the other end is connected with the pulse dust collector 3; The pipeline of the air duct 2 is also provided with a flow regulating valve 5;

[0013] The air outlet of the pulse dust collector 3 is connected to the induced draft fan 6, and the hopper 3a of the pulse dust collector 3 is vertically provided with a screw feeder 7, and the bottom of the hopper 3a of the pulse dust collector 3 is horizontally provided with a screw feeder 8 , the outlet of the screw feeder 8 is connected with the graphite negative pressure feeding system 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com