Model test device for the influence of double tunnel excavation on pile foundations that can realize multi-directional adjustment

A model test device, multi-directional technology, applied in the direction of basic structure test, measurement device, optical device, etc., can solve the problems of difficult to obtain soil parameters, damage, delay monitoring, etc., and achieve the effect of reducing boundary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

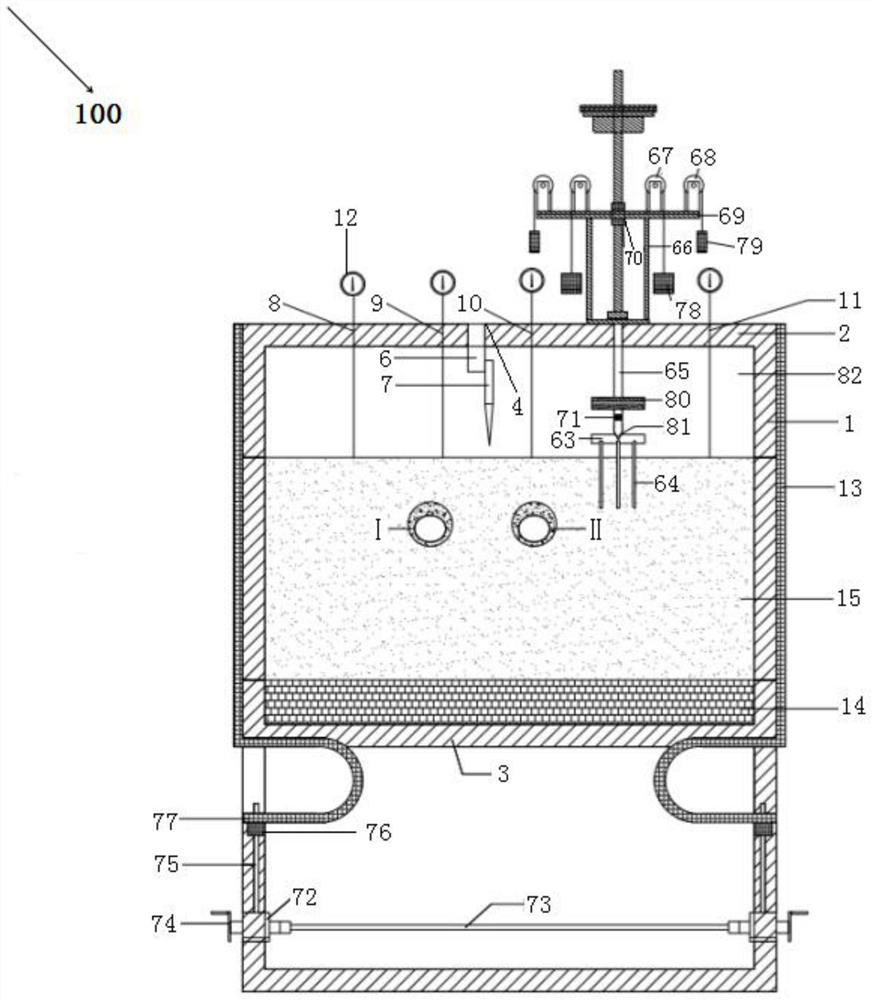

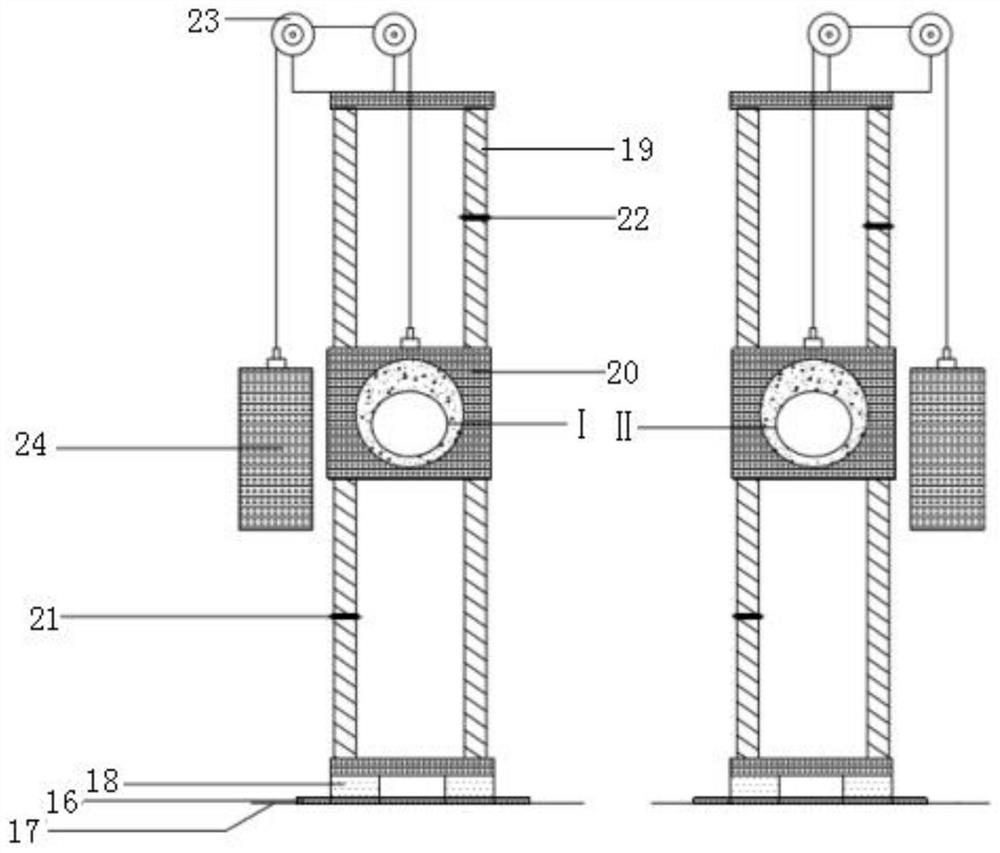

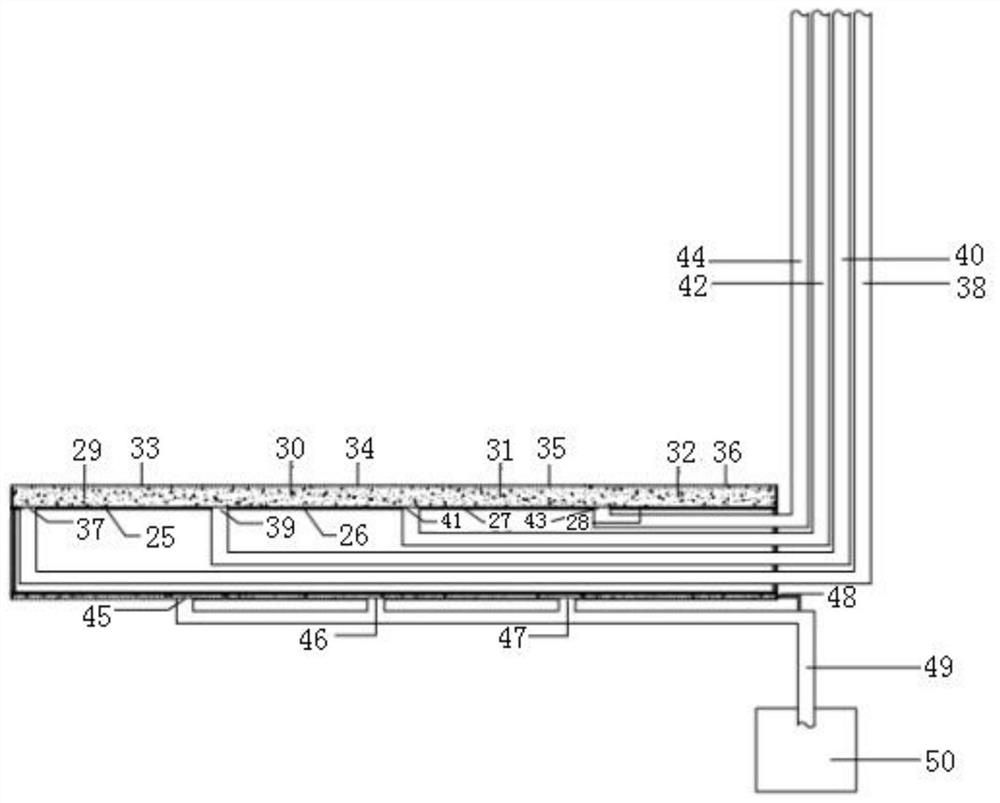

[0057] The adjustment of the relative position of the double-line tunnel is realized through the position control unit of the double-line tunnel. After adjusting the position of the double-line tunnel at the same horizontal position, tighten the stop screw 43 and the stop screw 45 to fix it, and fill in a certain height of aluminum rod 15 for simulation. Strata. Embed the pile group model on the simulated ground, and transfer the load through the contact between the pointed loading rod 65 in the pile group top concentrated load application device on the first crossbeam 2 and the center of the pile group model, and the concentrated load at the top of the pile group The load sensor 71 in the applying unit can measure the load value. Shaking the handle 74 makes the second aluminum plate 14 move slightly in the vertical direction through the transmission block 72, and adjusts the earth pressure distribution around the tunnel by reading the computer readings of twelve earth pressur...

Embodiment 2

[0059] The adjustment of the relative position of the double-line tunnel is realized through the position control unit of the double-line tunnel. After adjusting the position of the double-line tunnel at the same vertical position, tighten the stop screw 43 and the stop screw 45 to fix it, and fill in a certain height aluminum rod 15 Simulated strata. Embed the pile group model on the simulated stratum, and transmit the load through the contact between the pointed loading rod 65 in the pile group pile top concentrated load application unit on the first crossbeam 2 and the center of the pile group model, and the pile group pile top concentrates the load The load sensor 71 in the applying unit can measure the load value. Shaking the handle 74 makes the second aluminum plate 14 move slightly in the vertical direction through the transmission block 72, and adjusts the earth pressure distribution around the tunnel by reading the computer readings of twelve earth pressure sensors. ...

Embodiment 3

[0061] The adjustment of the relative position of the double-line tunnel is realized through the position control unit of the double-line tunnel. After the position of the double-line tunnel can be adjusted in an oblique position, the stop screw 43 and the stop screw 45 are fixed and fixed, and the aluminum rod 15 of a certain height is filled in. Simulated strata. Embed the pile group model on the simulated stratum, and transmit the load through the contact between the pointed loading rod 65 in the pile group pile top concentrated load application unit on the first crossbeam 2 and the center of the pile group model, and the pile group pile top concentrates the load The load sensor 71 in the applying unit can measure the load value. Shaking the handle 74 makes the second aluminum plate 14 move slightly in the vertical direction through the transmission block 72, and adjusts the earth pressure distribution around the tunnel by reading the computer readings of twelve earth press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com