A hand-held turning device

A kind of turning device, hand-held technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of multiple manpower, material resources and time, low maintenance efficiency, etc., to reduce the workload of disassembly and assembly, and prolong the use. Longevity, easy to move and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the accompanying drawings.

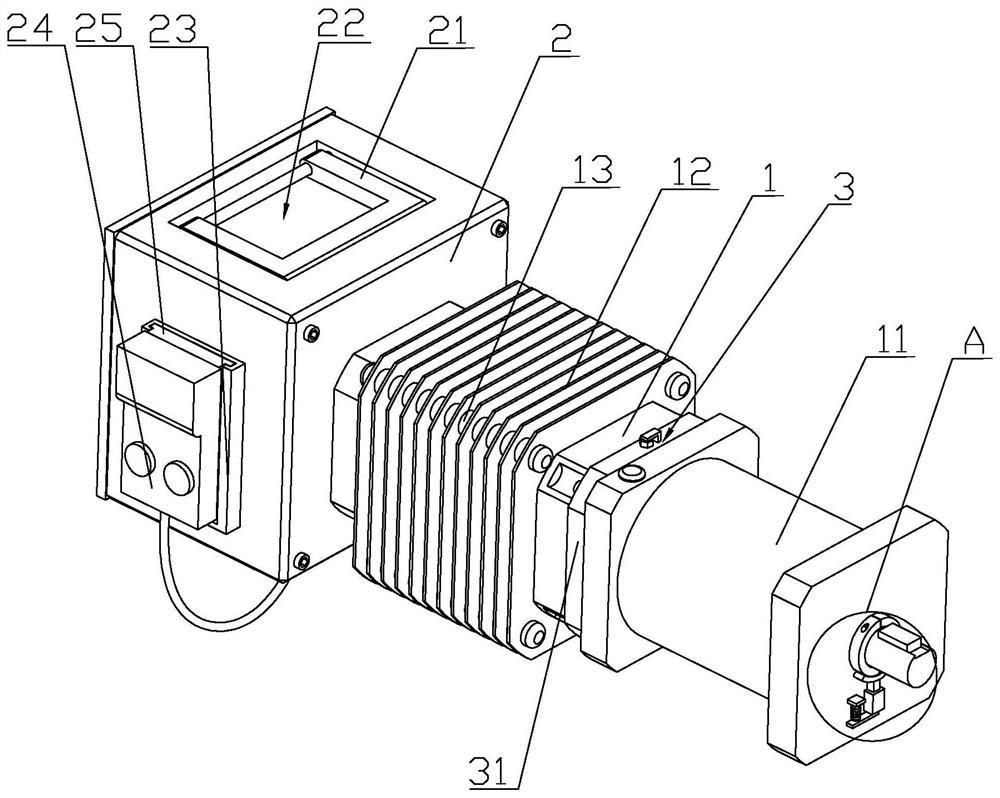

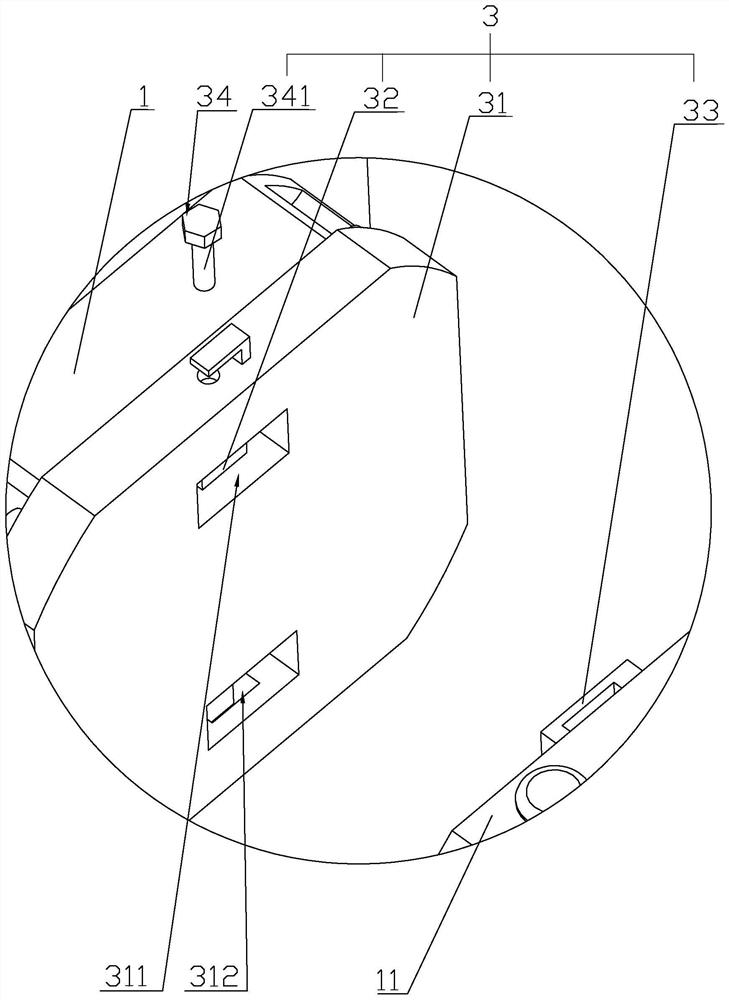

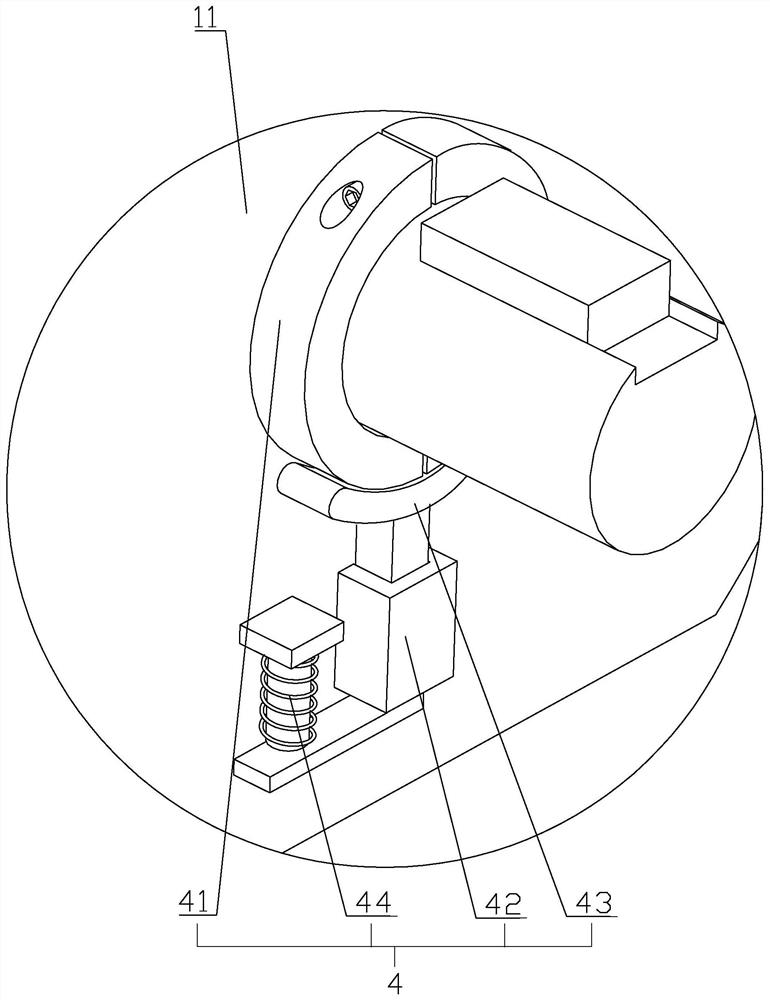

[0037] Refer figure 1 For a hand-held disk vehicle device disclosed in the present invention, a motor 1, a driver 2 disposed on the motor 1, is electrically connected to the driver 2 to control the handle 24 in which the motor 1 is inversion, and is disposed on the side of the motor 1. Used to increase the reducer 11 of the motor 1 to output torque. The reducer 11 is fixed with the output shaft of the motor 1, and the mounting mechanism 3 is provided between the motor 1 and the reducer 11. The driver 2 is electrically connected to the motor 1 to power the motor 1, and the motor 1 employs a servo motor 1 having a positive inversion function, and the handle 24 is electrically connected to the driver 2 to control the motor 1 is inversion. The reducer 11 employs the PRF90-L1 model, by reducing the speed of the motor 1 to increase the torque output by the speed reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com