Dolomite gravel soil roadbed filler based on orthogonal test design, and construction process thereof

An orthogonal test method, a technology of crushed stone, applied in the directions of roads, roads, buildings, etc., can solve the problems of not necessarily good gradation, the quality of roadbed cannot be guaranteed, and the composition of natural crushed stone soil is complex, etc. Alleviate financial pressure and reduce the effect of land acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention is a dolomite gravel mixture designed based on an orthogonal test method. The material is prepared from dolomite gravel, soil samples, mud and water, and the mass ratio of each component is: dolomite gravel : soil: mud content: water content = 1: 0.429: 0.014: 0.144.

[0025] In this embodiment, the maximum particle size of the dolomite gravel is 60mm.

[0026] In this embodiment, the soil sample is silty clay.

[0027] According to such scheme, the preparation method of described dolomite gravel soil may further comprise the steps:

[0028] 1), mix dry materials such as dolomite gravel, soil samples, mud at room temperature;

[0029] 2) Add water to the dry mixture mixed in 1), and stir quickly.

Embodiment 2

[0031] A kind of construction technique based on the earth-rock mixture of the dolomite crushed stone described in above-mentioned embodiment 1 design by orthogonal test method, comprises the following steps:

[0032] 1) Excavation of earth and stone: transport the dolomite gravel and silty clay that meet the requirements from the excavation area to the construction operation section on site;

[0033] 2) Mix dolomite gravel with silty clay in proportion and stir evenly, wherein the proportion of soil and rock is 60% to 80%, and the mud content in the soil is 1% to 3%;

[0034] 3) After drying the soil and flattening it, first measure whether the water content of the filler is within the range of the optimal water content ± 2%, otherwise it should be spread out to dry or add water evenly until the water content is within the range of the optimal water content ± 2%, and Stir well again;

[0035] 4) Filling, leveling and rolling.

Embodiment 3

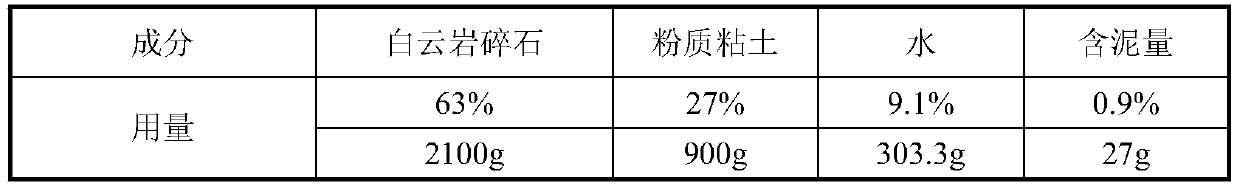

[0037]

[0038] According to the composition ratio in the above table, the construction process is carried out according to the construction process of Example 2. In this example, the CBR value of dolomite gravel soil is 23.4, the roadbed has high bearing capacity, small deformation, strength meets the requirements of roadbed filling, and good durability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com