A kind of polyamide composite material and preparation method thereof

A composite material and polyamide technology, which is applied in the field of polyamide composite materials and its preparation, can solve problems such as poor laser transmittance, influence of laser welding effect, weak welding strength, etc., to improve appearance defects and seams Continuity Problems, Improved Laser Welding Performance, Effect of Improving Continuity Problems

Active Publication Date: 2022-06-07

SHANGHAI KINGFA SCI & TECH +3

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the choice of resin will also have varying degrees of impact on the laser welding effect

According to the welding effect, the defects of laser welding include: 1) weak welding strength; 2) unsatisfactory appearance

The reasons for the weakening of the welding strength are: the thickness of the part through the laser is too high or the laser transmittance is not good, so that the laser energy cannot fully reach the welding interface; there is a resin interface that is not fully melted and connected at the joint to generate heat. Mass conduction, or there is a gas cavity formed by the decomposition of laser ablation at the junction

Moreover, through laser welding, flashing will also occur: there are several reasons for flashing: 1. The fluidity of the material is too high, and the melting point or plasticizing temperature is low, that is, it is easy to overflow; 2. The gas generated by the decomposition of the material promotes melting Partial overflow; 3. High transmittance or high input laser power of the equipment, which promotes the occurrence of points 1 and 2

[0004] DuPont and BASF are looking for ways to improve laser welding from the aspect of pigments. For example, CN01804783 and WO2017EP052758 disclose the use of 2:1 type azo metal complexes, which do not solve the impact of components other than pigments on laser welding, and it is possible to add other pigments It will lead to an increase in cost, a decrease in some performance and a decrease in durability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

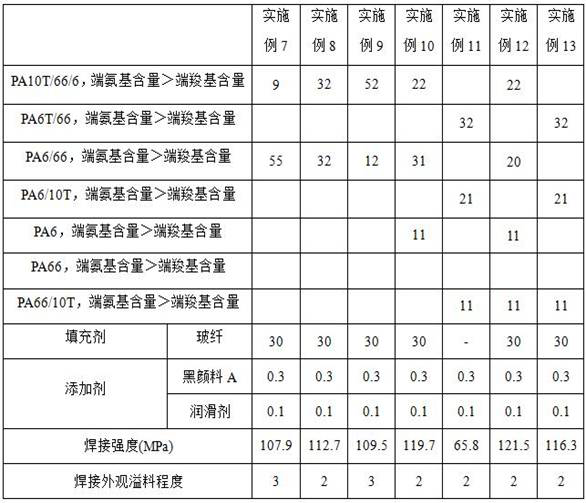

[0054] The preparation method of embodiment and comparative example polyamide composite material: According to the proportioning of table 1, all components are dried to moisture content lower than 1500ppm; Mixed, and then extruded, cooled and pelletized through a twin-screw extruder to obtain a polyamide composite material.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a polyamide composite material, which comprises the following components in parts by weight: A) 20-80 parts of at least one polyamide E and at least one of polyamide I, polyamide II and polyamide III compounding; the polyamide-terminated ammonia E, polyamide I, polyamide II, and polyamide III group content > carboxyl-terminated content; B) 0-35 parts of filler. The polyamide composite material of the invention has the advantages of good laser welding effect and the like.

Description

technical field [0001] The invention relates to the technical field of polymer materials, in particular to a polyamide composite material and a preparation method thereof. Background technique [0002] Due to its excellent mechanical properties, chemical resistance, ease of processing, and fatigue creep resistance, polyamide materials are often used in electronic appliances, power tools, and motor vehicle industries that require harsh working environments. In the automotive industry, polyamide materials are also widely used in interior and exterior trim parts, functional parts and structural parts. Lightweight as the development trend of automotive materials, there are more and more plastic parts under the hood of automobiles. In order to obtain auto parts with high structural strength, most of the polyamide composite materials used in vehicles are now laser welded, and the obtained parts have small seams, high strength and long service life. Laser welding parts generally ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L77/06C08L77/02C08K7/14

CPCC08L77/06C08L77/02C08L2205/025C08L2205/035C08K7/14

Inventor 林洁龙丁正亚杨波张超肖军华陈延安孙刚罗忠富叶士兵冯嘉春卢先博张勇

Owner SHANGHAI KINGFA SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com