Shield tunneling machine capable of measuring water content of muck, and water content measurement method

A technology of moisture content and shield machine, applied in the field of shield machine, can solve the problems of poor integration of shield machine, affecting the driving efficiency, unable to monitor the situation of dregs in real time, etc., to achieve good integration, improve construction efficiency and construction safety. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

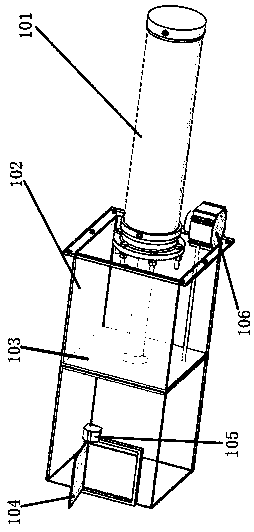

[0038] Example 2, such as image 3 As shown, a shield machine that can measure the moisture content of slag, the slag feeding mechanism 1 includes a feed bin 102, the feed bin 102 is sealed with the pressurization bin body 210 of the pressurizing device 2, and the feed bin 102 communicates with the pressurized bin body 210 through the second gate 201, that is, the muck in the feeding bin enters the muck bin through the second gate. A first push plate 103 is arranged inside the feed bin 102, and the area of the first push plate 103 is similar to the cross-sectional area of the feed bin, and its area can be set as S2. The first push plate 103 is connected with the drive mechanism 101 that is arranged on the side wall of the feed bin 102, and the drive mechanism 101 promotes the first push plate 103 to move in the feed bin 102. When the muck bin needs to enter the slag, the second The gate is opened, the driving mechanism is stretched out, and the muck is pushed into the muc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com