A gas circuit contact and an electrical connector with the gas circuit contact

A contact piece and gas circuit technology, which is applied to connections with fluid cut-off devices, pipes/pipe joints/fittings, passing components, etc., can solve the problem that gas circuit holes cannot be closed, affect gas transmission, and gas medium volume flow is small and other problems, to achieve the effect of convenient and quick pipeline connection, large cross-sectional area of gas path, and easy installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

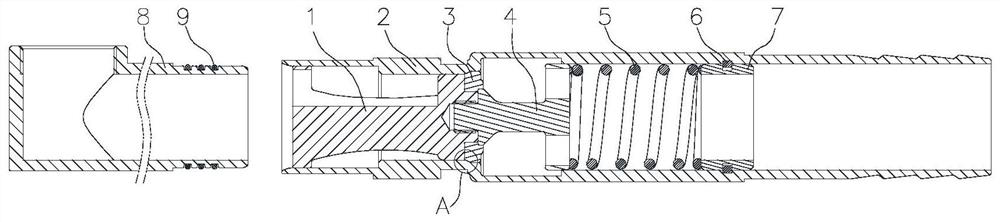

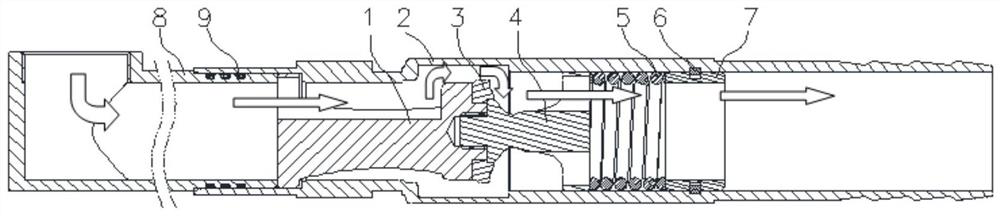

[0059] like Figure 1 to Figure 12 As shown, a gas path contact piece includes a gas path pin 8 and a gas path jack 2. Both the gas path pin 8 and the gas path jack 2 are provided with a through hole to form a gas medium transmission channel. The inner hole of the hole 2 is provided with a valve body 1, a sealing body 3, a valve seat 4 and a return spring 5, wherein the valve body 1 and the valve seat 4 are fixedly connected by threads, and a sealing body is arranged between the valve body 1 and the valve seat 4 3. The sealing body 3 is attached to the inner hole wall of the gas passage socket 2, so that a seal is formed between the inside of the gas passage socket 2 and the external environment. One end of the return spring 5 is in contact with the valve seat 4, and the other end of the return spring 5 is fixed on the In the inner hole of the gas path socket 2 , the return spring 5 can provide elastic force to ensure that the sealing body 3 fits with the inner hole of the gas...

Embodiment 2

[0081] like Figures 13 to 15 As shown, on the basis of the structure of the first embodiment, the following changes are made:

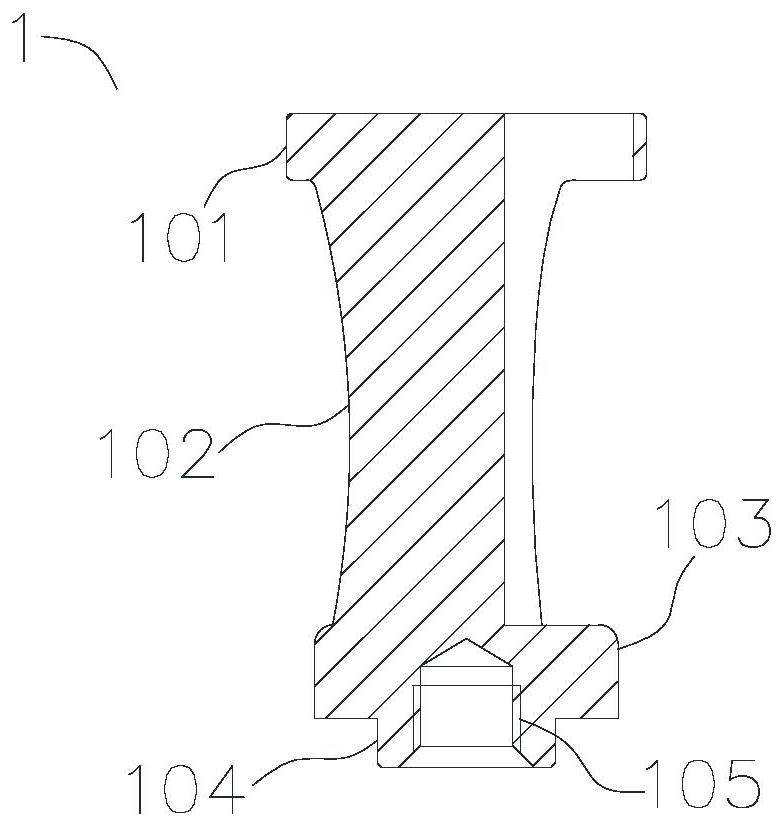

[0082] The connecting strut 102 is a cylinder with rounded corners at both ends of the cylinder to increase the structural strength of the valve body. Compared with the special-shaped strut structure in Example 1, the cylindrical structure is easy to process, but the special-shaped strut ensures that the cross-sectional area of the gas path is greater than Under the condition that it is equal to the cross-sectional area of the inner hole of the air passage jack 8, it has higher structural strength.

[0083] The middle of the fourth section hole 204 is provided with a ring groove 206, the ring groove 206 is provided with a retaining ring 10, the retaining ring 10 is fixed in the ring groove 206 by its own elastic force, the inner ring of the retaining ring 10 extends out of the ring groove 206, and the retaining ring 10 is in contact with the ret...

Embodiment 3

[0087] like Figure 16 to Figure 18 As shown, on the basis of the structure of the first embodiment, the following changes are made:

[0088] Increase the size of the outer diameter of the third hole 203, increase the clearance between the third hole 203 and the valve body 1, the sealing body 3 and the valve seat 4, increase the air path, and increase the air path at the minimum cross section (sealing body 3 and valve seat 4). The ratio of the gap between the holes 203 in the third section) to the cross-sectional area of the inner hole of the air passage jack 8 can also reach 1:1, that is, any cross-sectional area of the inner hole of the air passage jack 2 is greater than or equal to the inner hole of the air passage jack 8 The cross-sectional area ensures the smooth transmission of the gas medium and meets the cooling requirements.

[0089] The first sealing surface 205 is a tapered surface, the second sealing surface 302 is a tapered surface, and the seal formed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com