Telescopic settlement pipe, and settlement deformation monitoring system and method

A deformation monitoring and settlement monitoring technology, which is applied in the field of settlement deformation monitoring system and telescopic settlement tube, can solve the problems of easy degaussing of the electromagnetic settlement ring, high requirements for embedding accuracy, and failure of normal observation of the settlement tube, etc., and achieve the effect of clear marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

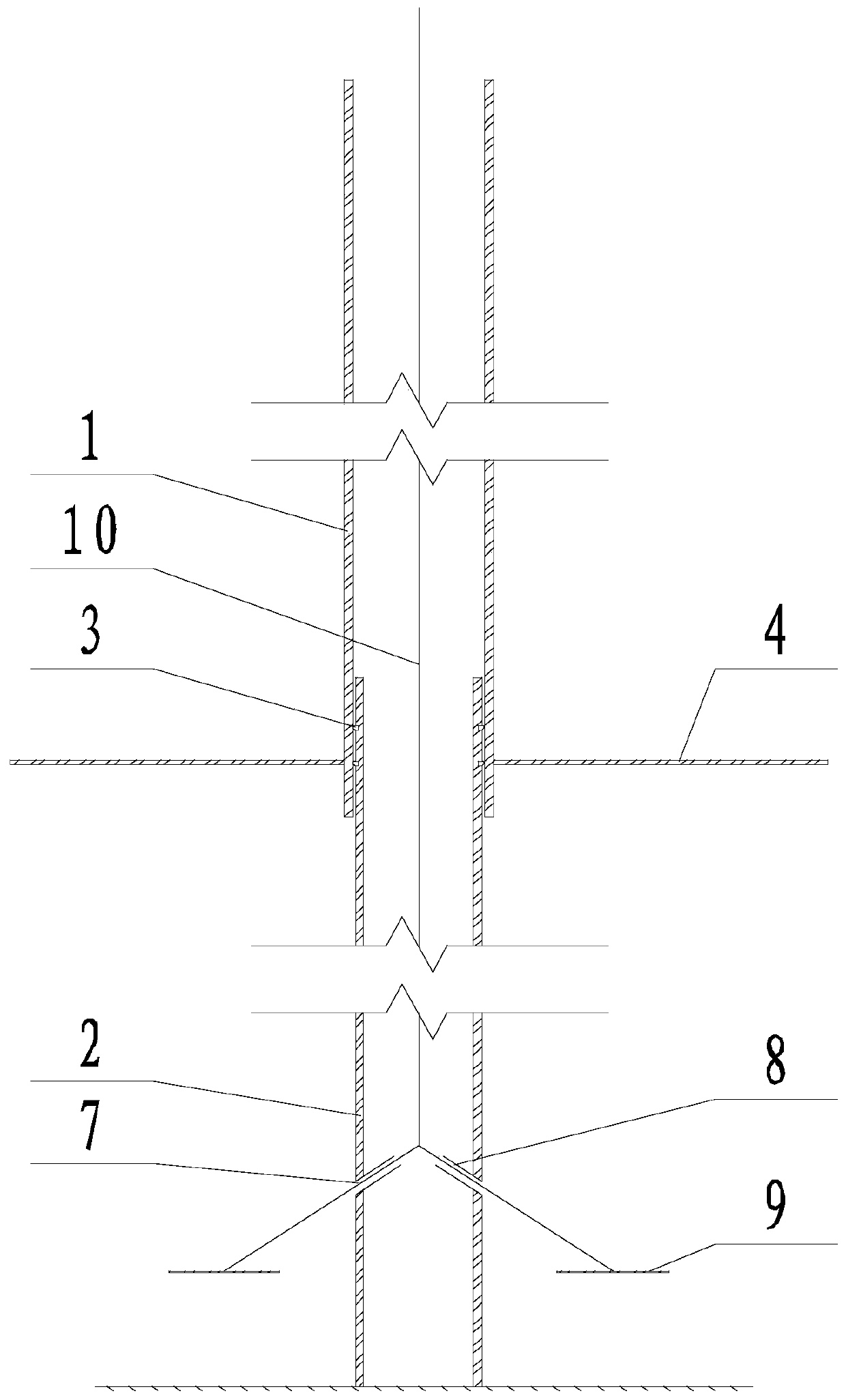

[0047] Such as figure 1 The telescopic settling tube shown includes a first pipe 1 and a second pipe 2 that are inserted into each other, the first pipe 1 is located above the second pipe 2, and the connection between the first pipe 1 and the second pipe 2 The sealing member 3 is stuffed in the gap; the lower periphery of the first pipeline 1 is provided with a transverse plate 4 , and the transverse plate 4 is perpendicular to the axis of the first pipeline 1 . In this embodiment, the inner diameter of the upper first pipeline 1 is larger than the outer diameter of the second pipeline 2 . The sealing member 3 in this embodiment is preferably several rubber sealing rings.

Embodiment 2

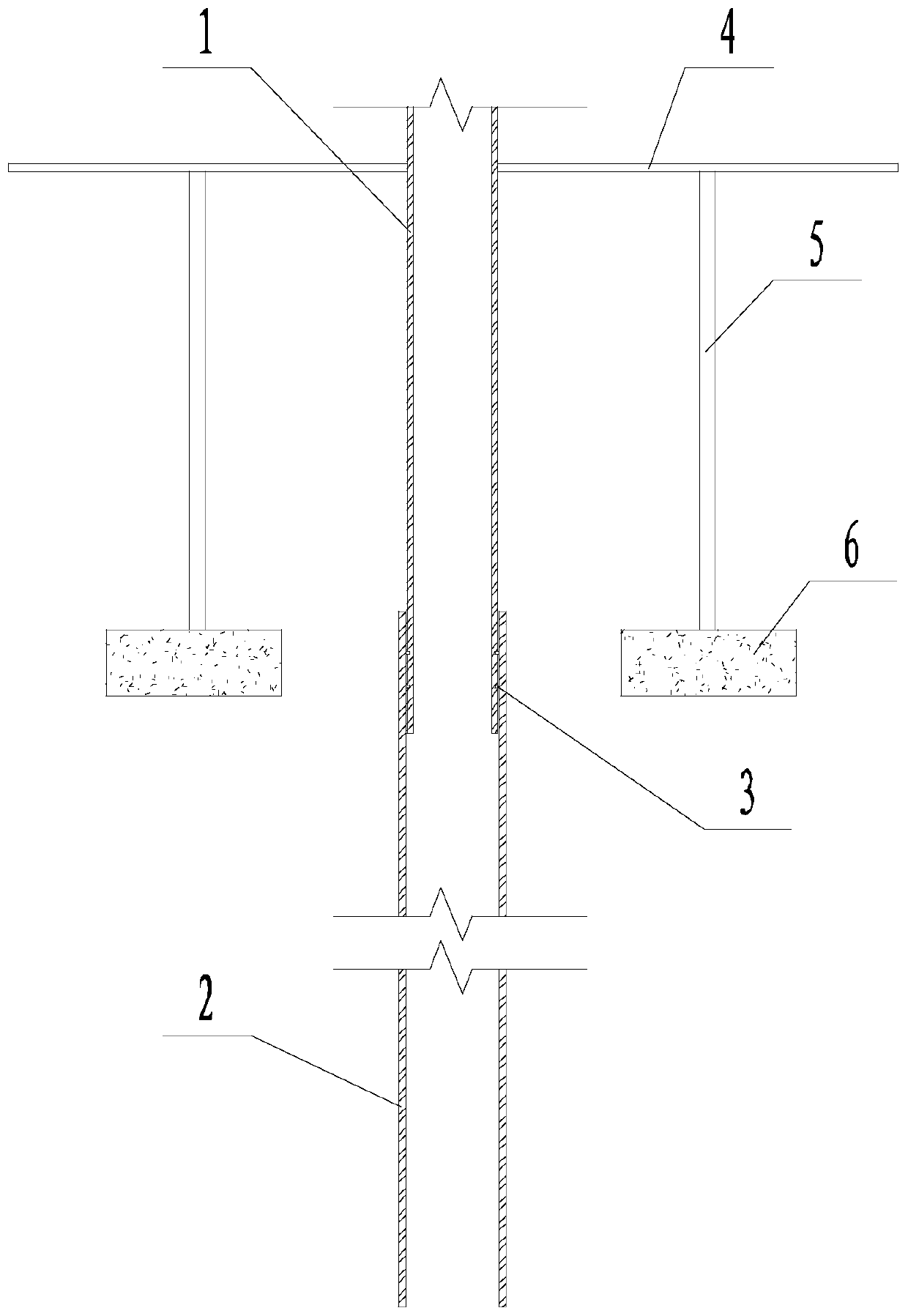

[0049] Such as figure 2 In the telescopic settling tube shown, on the basis of Embodiment 1, the bottom of the transverse plate 4 is connected to the support plate 6 through the connecting rod 5 . The first pipeline 1 and / or the second pipeline 2 are provided with several wire passing holes 7 . The inner wall of the first pipe 1 and / or the second pipe 2 is provided with a ferrule 8 communicating with the wire passing hole 7 , and the ferrule 8 is inclined from inside to outside and downward along the radial direction. Both the first pipeline 1 and the second pipeline 2 are seamless steel pipes. In this embodiment, the outer diameter of the upper first pipeline 1 is smaller than the inner diameter of the second pipeline 2 .

Embodiment 3

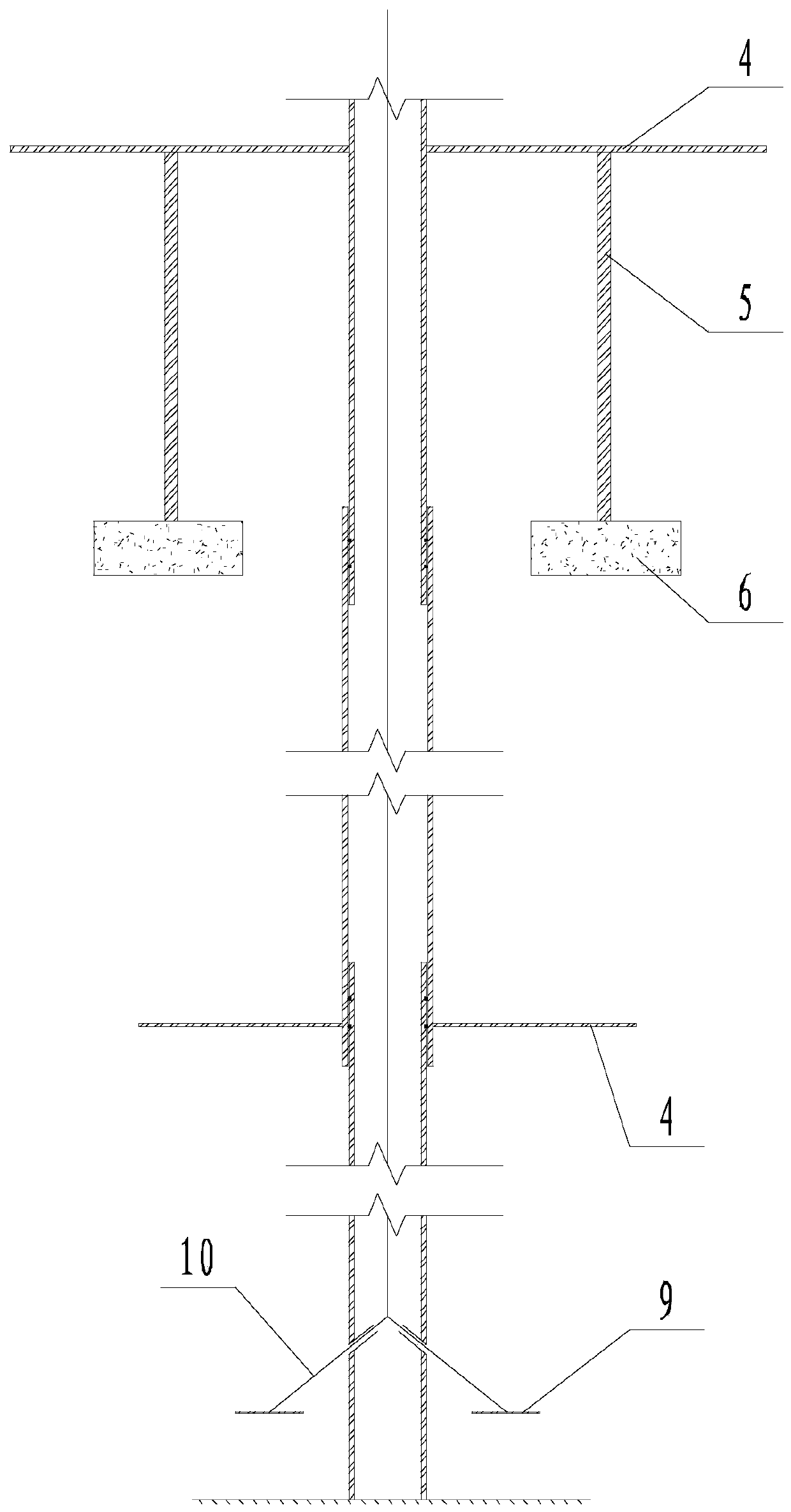

[0051] In this embodiment, the telescopic settling pipe is formed by inserting several sections sequentially, such as image 3 There are three sections of pipelines shown in total, the middle section is the thicker first pipeline, and the upper and lower sides are the second pipelines. By analogy, the gradual insertion of the telescopic settlement pipe from the river bed foundation to the dam surface can be realized. This embodiment fully considers the high internal confining pressure of the core wall of the high rockfill dam, and the characteristics that the pipes traditionally connected by welding are not suitable for deformation, and the buried pipes are connected by sockets. The design takes advantage of the difference in diameter between two adjacent sections of pipelines. The small-diameter pipeline is inserted into the large-diameter pipeline for a certain length. Rubber and other materials with good sealing performance are used between the two pipelines to achieve a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com