Preparation method of 3D flexible tin disulfide/graphene gas sensor for nitrogen dioxide detection

A gas sensor and nitrogen dioxide technology, applied in instruments, measuring devices, scientific instruments, etc., to achieve the effect of improving the overall detection performance and reducing the resistance value of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

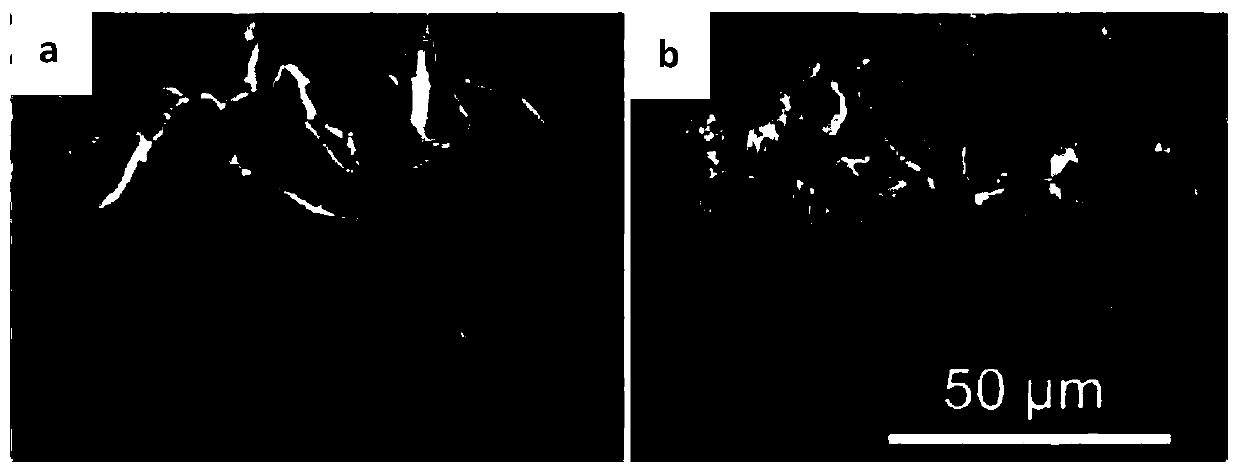

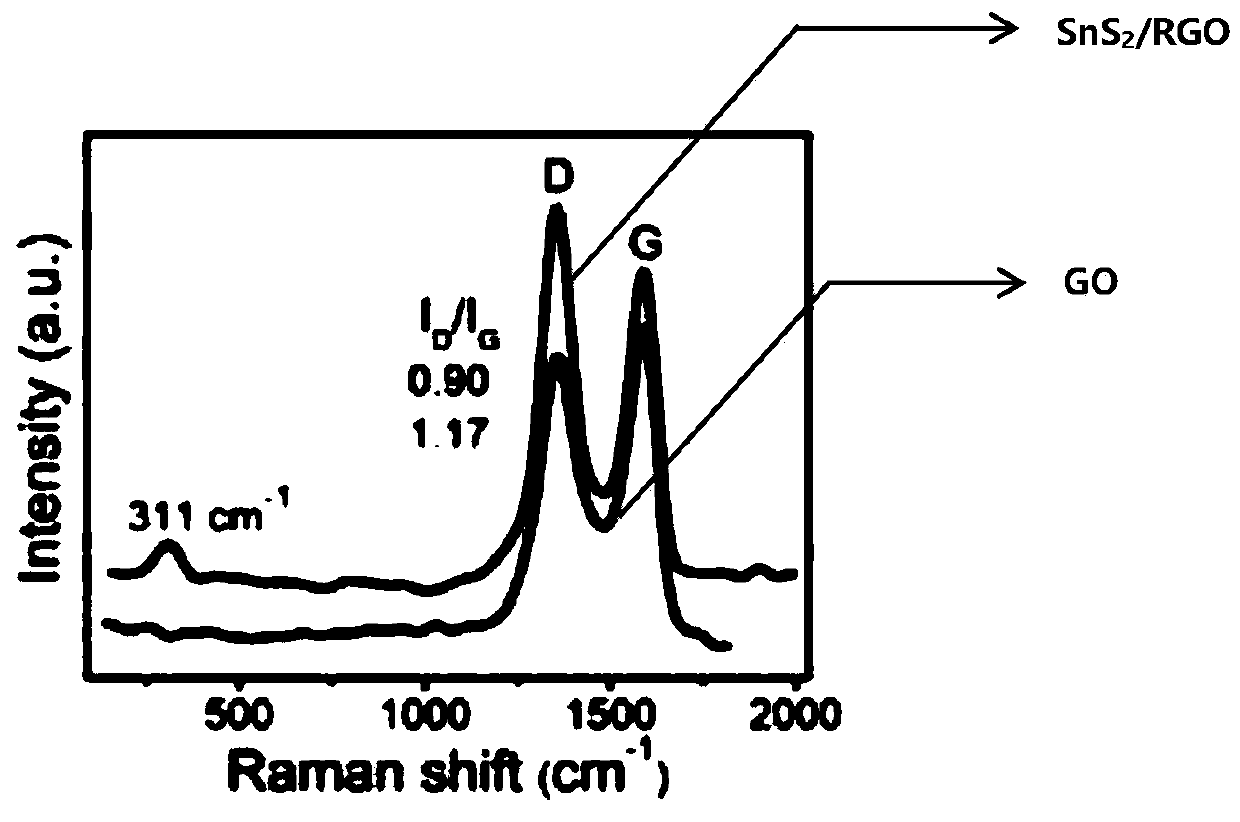

[0052] 3D Flexible SnS 2 Preparation of / RGO gas sensor:

[0053] (1) 3D SnS 2 / Preparation of RGO

[0054] Under continuous stirring conditions, add 0.30g of thioacetamide and 0.35g of tin chloride pentahydrate into 20mL of graphene oxide solution with a concentration of 0.2mg / mL, and the resulting mixture is ultrasonically dissolved and then transferred to a reaction kettle at 180°C After heating for 11 h, the resulting product was centrifuged and washed with deionized water to obtain solid SnS 2 / RGO product.

[0055] (2)SnS 2 Preparation of / RGO gas sensor

[0056] Use a photoresist to bind a double-sided copper-clad LCP film on a silicon wafer with a thickness of 300 μm, remove the exposed copper layer on the surface of the LCP film by etching, and spin-coat a photoresist layer with a thickness of 5 μm on the surface. Sputtering 8nm Cr / 280nm Au layer, using lift-off technology to process interdigitated electrodes on the LCP substrate, the solid SnS prepared in the ...

Embodiment 2

[0059] 3D Flexible SnS 2 Preparation of / RGO gas sensor:

[0060] (1) 3D SnS 2 / Preparation of RGO

[0061] Under the condition of continuous stirring, add 0.60g of thioacetamide and 0.70g of tin chloride pentahydrate into 40mL of graphene oxide solution with a concentration of 0.2mg / mL. After heating for 10 h, the resulting product was centrifuged and washed with deionized water to obtain solid SnS 2 / RGO product.

[0062] (2)SnS 2 Preparation of / RGO gas sensor

[0063] Use a photoresist to bind a double-sided copper-clad LCP film on a silicon wafer with a thickness of 300 μm, remove the exposed copper layer on the surface of the LCP film by etching, and spin-coat a photoresist layer with a thickness of 5 μm on the surface. Sputtering 8nm Cr / 280nm Au layer, using lift-off technology to process interdigitated electrodes on the LCP substrate, the solid SnS prepared in the step S1 2 / RGO was re-dispersed in deionized water to prepare an aqueous dispersion with a concent...

Embodiment 3

[0065] 3D Flexible SnS 2 Preparation of / RGO gas sensor:

[0066] (1) 3D SnS 2 / Preparation of RGO

[0067] Under the condition of continuous stirring, add 0.90g of thioacetamide and 1.05g of tin chloride pentahydrate into 60mL of graphene oxide solution with a concentration of 0.2mg / mL. After heating for 12 h, the resulting product was centrifuged and washed with deionized water to obtain solid SnS 2 / RGO product.

[0068] (2)SnS 2 Preparation of / RGO gas sensor

[0069] Use a photoresist to bind a double-sided copper-clad LCP film on a silicon wafer with a thickness of 300 μm, remove the exposed copper layer on the surface of the LCP film by etching, and spin-coat a photoresist layer with a thickness of 5 μm on the surface. Sputtering 8nm Cr / 280nm Au layer, using lift-off technology to process interdigitated electrodes on the LCP substrate, the solid SnS prepared in the step S1 2 / RGO was re-dispersed in deionized water to prepare an aqueous dispersion with a concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com