Power-saving control system and method for gypsum board production line

A technology of power-saving control and gypsum board, applied in general control system, control/regulation system, electrical program control, etc., can solve the problems of low power-saving work efficiency in production lines, improve equipment management level, avoid human intervention, The effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

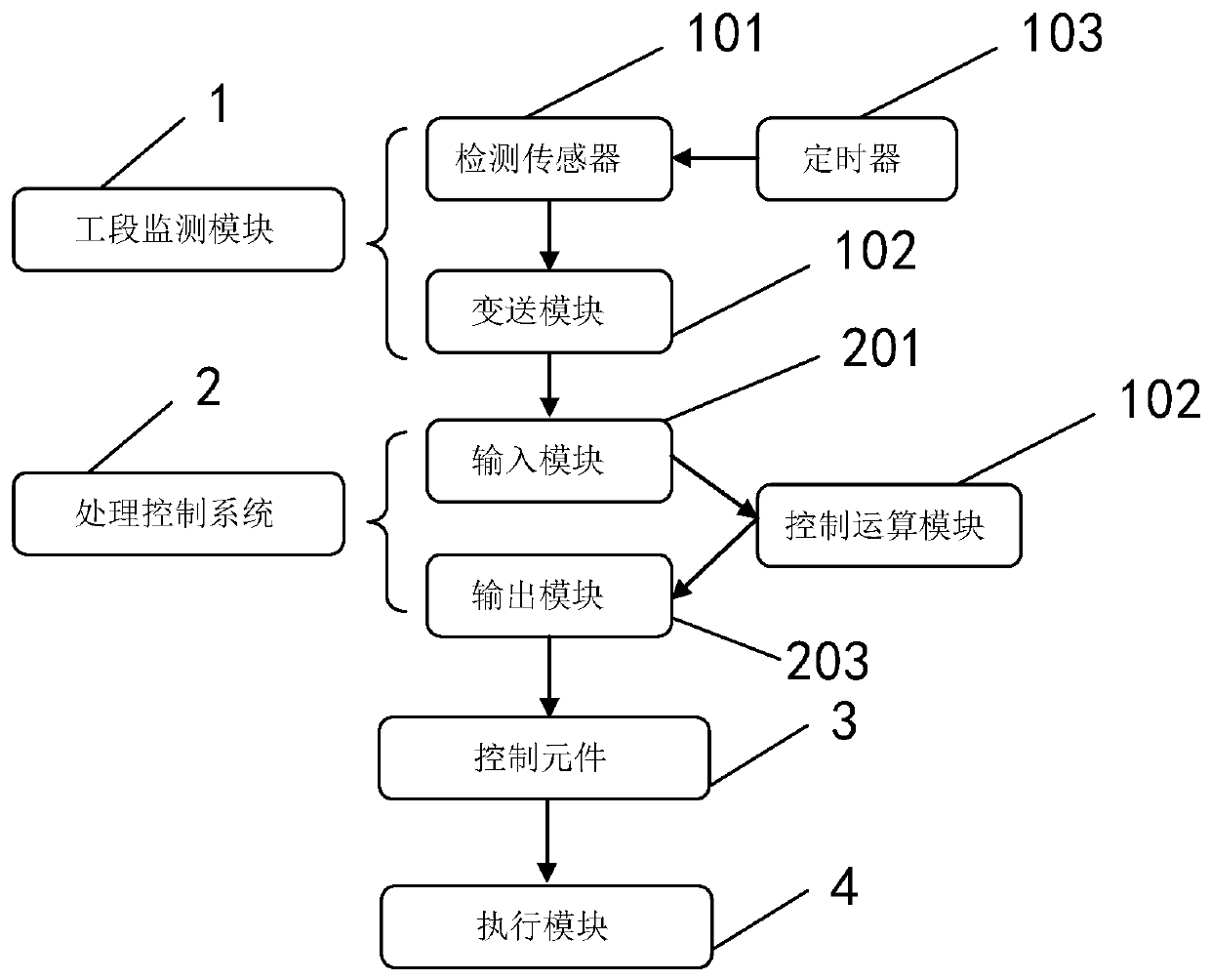

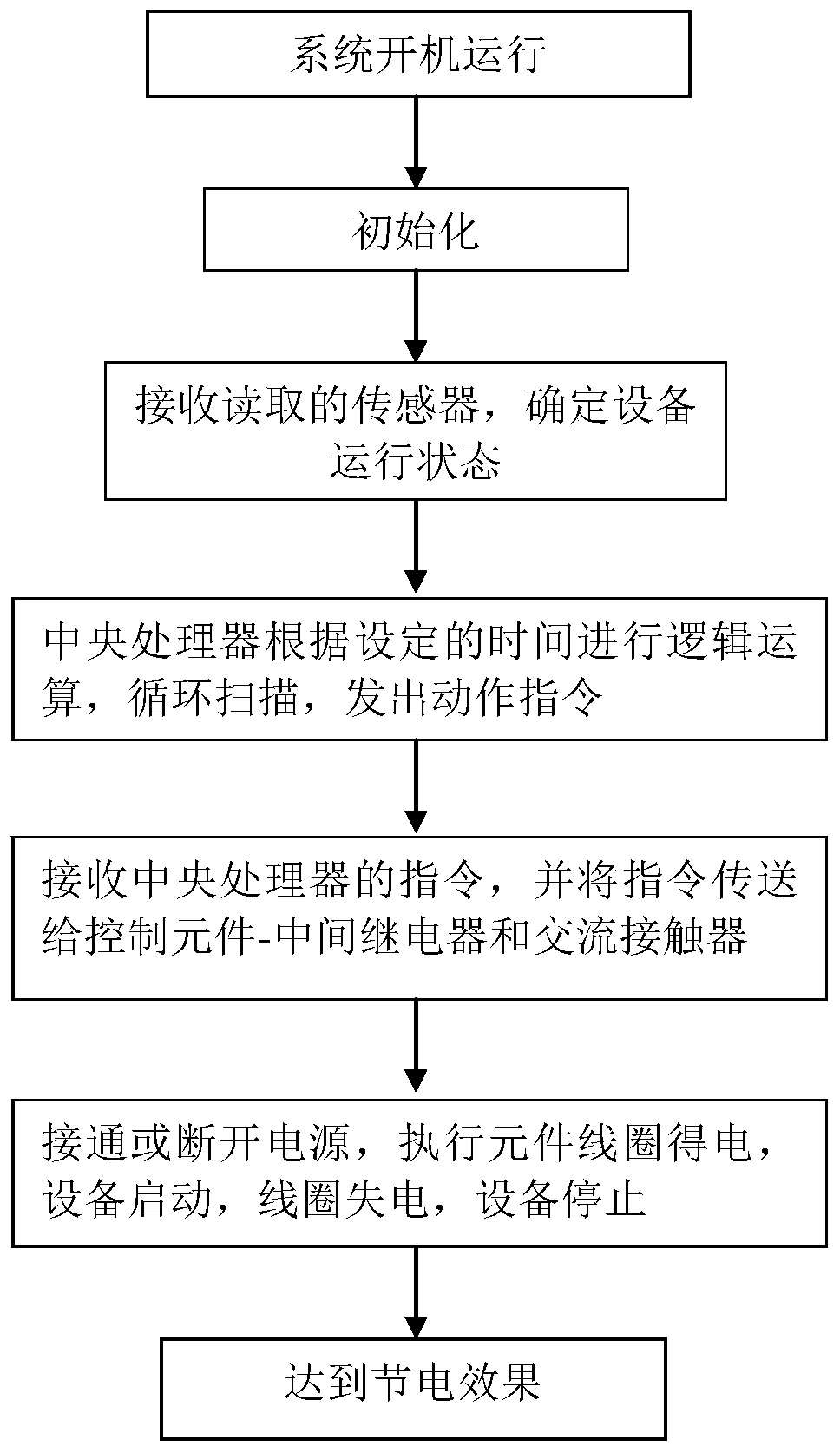

[0039] like figure 1 and figure 2 As shown, the present invention provides a power-saving control system for a gypsum board production line. This embodiment obtains the working data of multiple operating sections by monitoring the working status of multiple operating sections on the gypsum board production line. In the event of failure or failure, timely control the operation section to stop working, so as to effectively control the start and stop of the operation section according to the specific use of the equipment in the operation section, greatly improving the utilization rate of equipment and reducing power consumption.

[0040] At the same time, the energy-saving control system of this embodiment obtains the parameters of different operating sections through different detection sensors, completely avoids human intervention, improves the level of automation and equipment management, avoids economic losses caused by equipment failures, and achieves the expected energy-sa...

Embodiment 2

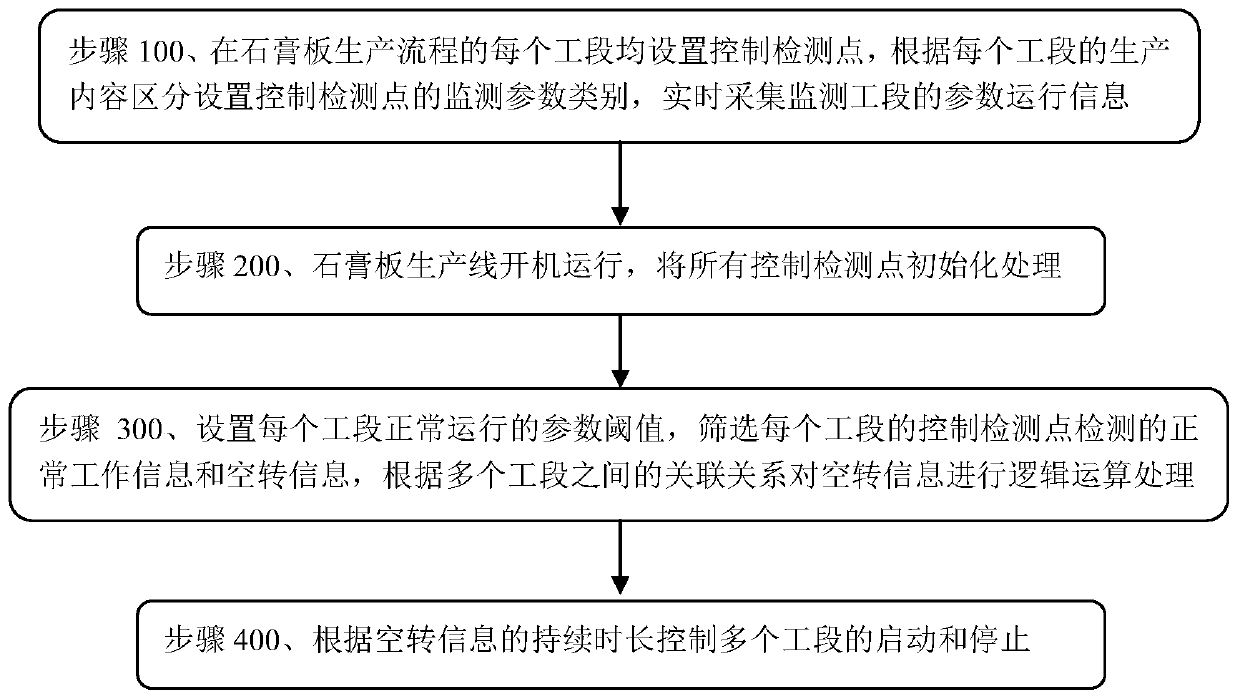

[0052] like image 3 As shown, in order to avoid idling on the gypsum board production line when the material supply on the conveyor belt is not timely, the present invention provides a power-saving control method for the gypsum board production line, which increases each operating section of the gypsum board production line At the material detection point, when there is no material delivery within the threshold time, it is considered that the current gypsum board production line is idling, and the movement of the gypsum board production line is suspended, thereby avoiding the waste of resources caused by the continuous idling of the production line.

[0053] Specifically include the following steps:

[0054] First of all, control detection points are set in each operation section of the gypsum board production process, and the monitoring parameter categories of the control inspection points are set according to the production content of each operation section, and the paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com