Hydrogen production method and device of non-electric heating quick-start hydrogen storage material

A hydrogen storage material and quick-start technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., to achieve the effects of low cost, simple and easy preparation process, and high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

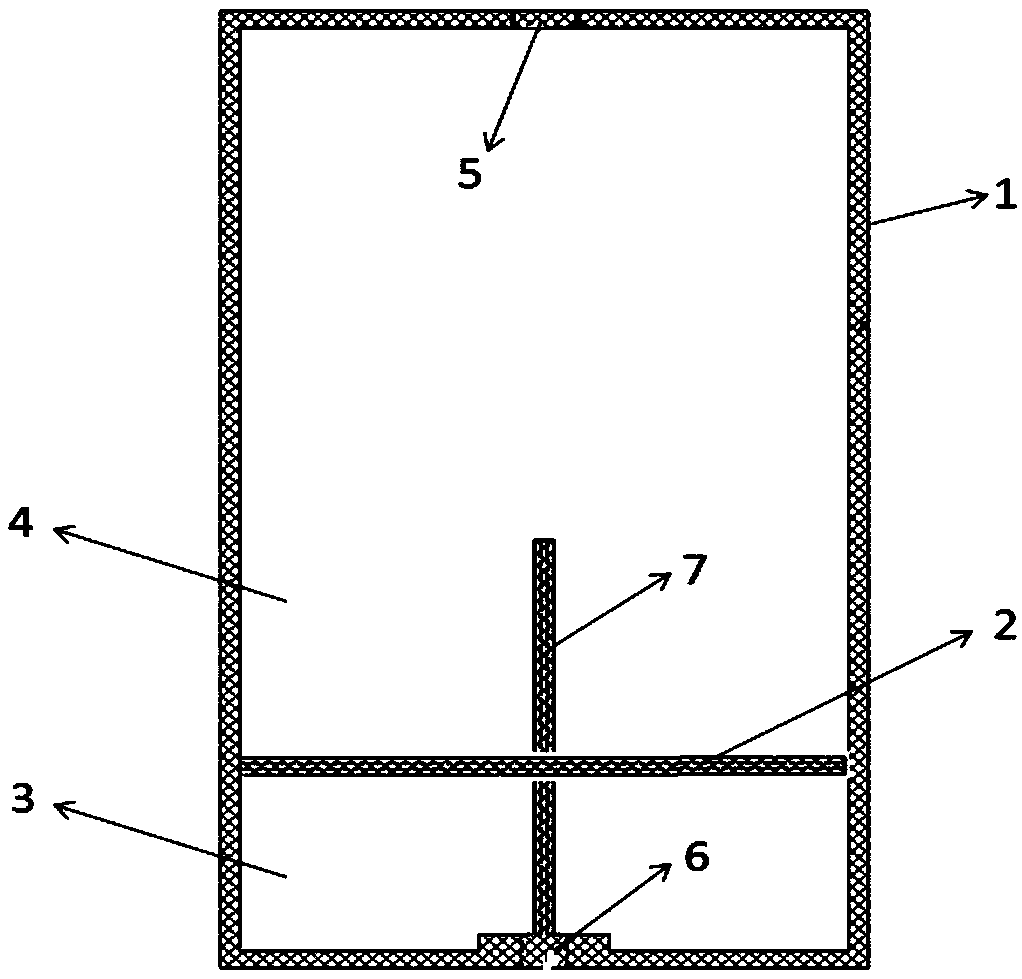

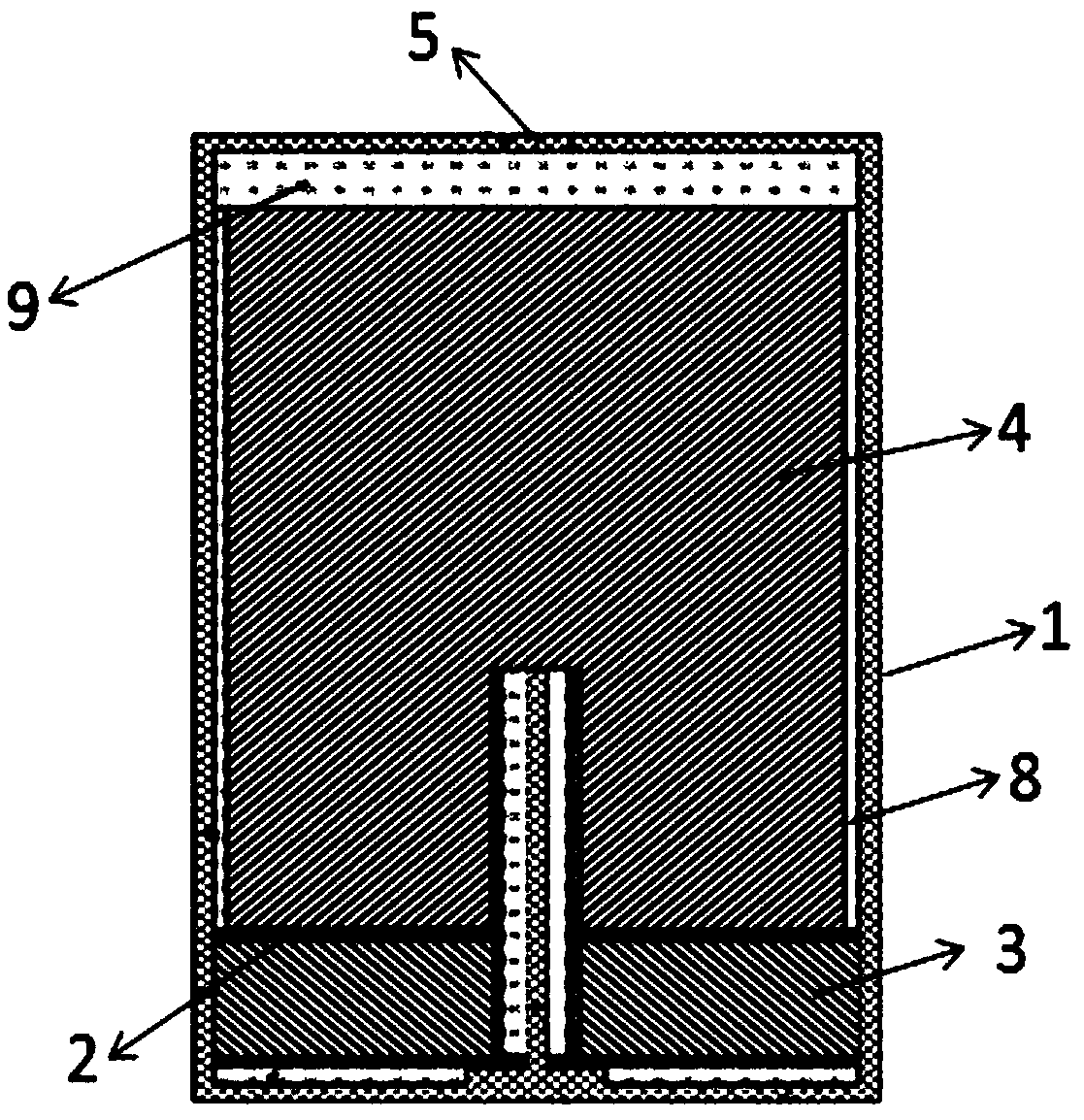

[0040] Such as figure 2 As shown, the present invention provides a device for quickly starting hydrogen production from hydrogen storage materials without electric heating, which includes a hollow shell 1, and a layer of isolation net 2 is horizontally arranged in the housing 1, and the isolation net 2 is preferably 0.3mm Thick nickel mesh, the isolation mesh 2 divides the internal space of the housing 1 into the reaction powder A storage room 3 in the lower part and the reaction powder B storage room 4 in the upper part, and the upper top of the housing 1 is provided with The air outlet 5 and the bottom are provided with a water inlet 6, the air outlet 5 communicates with the reaction powder B storage room 4, and the water inlet 6 is connected to the reaction powder A storage room through a vertical water inlet distribution pipe 7. 3 and the reaction powder B storage chamber 4 to deliver water, the housing 1 is provided with a water supply assembly connected with the water i...

Embodiment 2

[0044] The reaction powder A storage chamber and the reaction powder B storage chamber of the hydrogen production device provided in Example 1 are respectively filled with the reaction powder A and the reaction powder B, and the mass ratio of the mass of the reaction powder A to the reaction powder B after filling can be 0.0001-1:1 (specifically 0.25:1 in this embodiment, put 10g of reaction powder A into the storage room of reaction powder A, and put 40g of reaction powder B into the storage room of reaction powder B).

[0045] The above reaction powder A is a mixed powder of aluminum powder and calcium oxide, and the mass ratio of aluminum powder and calcium oxide powder can be 0.01-200:1 (specifically 3:2 in this embodiment).

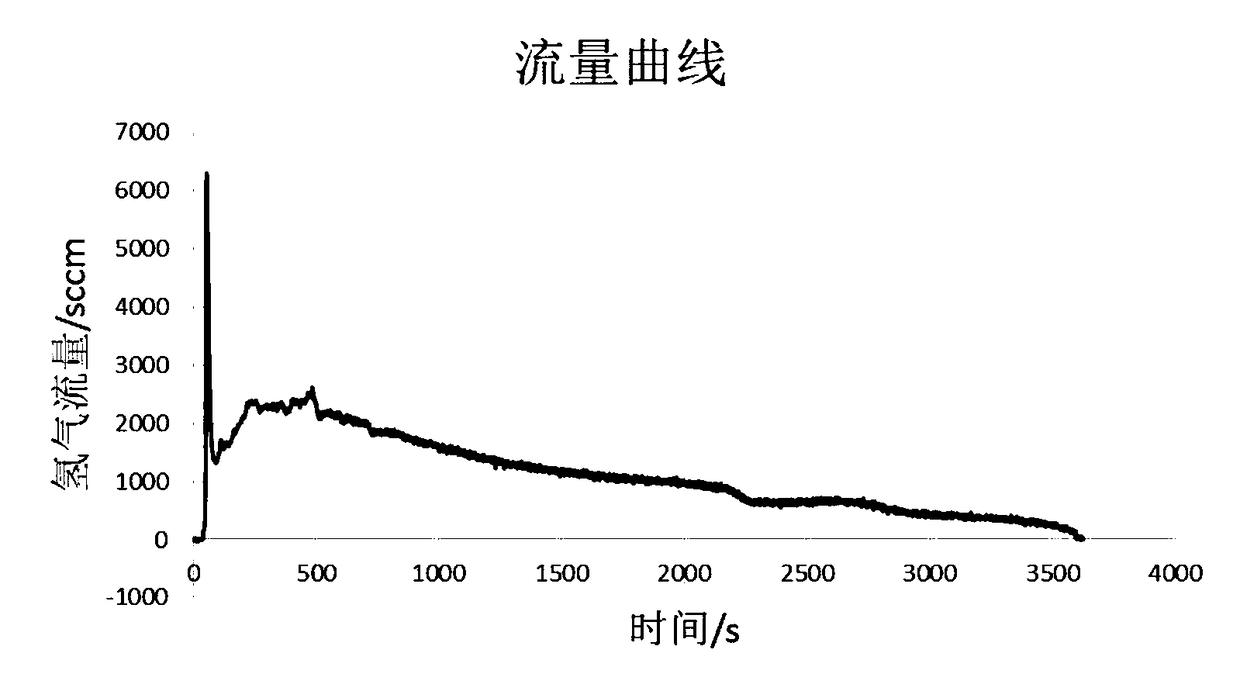

[0046] The above-mentioned reaction powder B is a mixed powder of sodium hydroxide and magnesium hydride, the mass ratio of sodium hydroxide and magnesium hydride can be 0.01-0.1:1 (specifically 0.1:1 in this embodiment), and it is mixed under nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com