Electric vehicle temperature control system

A temperature control system, a technology for electric vehicles, applied in battery temperature control, circuits, electrical components, etc., can solve the problems of low battery cooling efficiency, battery temperature control within an ideal range, low battery ambient temperature, etc., to improve energy utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

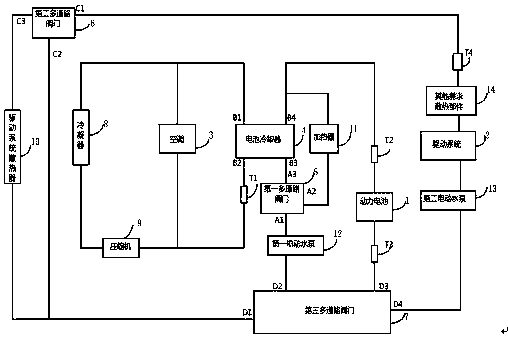

[0028] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

[0029] Please refer to figure 1 As shown, the present invention provides a temperature control system for electric vehicles, including: power battery 1, drive system 2, air conditioner 3, battery cooler 4, first multi-channel valve 5, second multi-channel valve 6, third multi-channel valve Valve 7, wherein the power battery 1 is connected between the first multi-channel valve 5 and the third multi-channel valve 7, the driving system 2 is connected between the second multi-channel valve 6 and the third multi-channel valve 7, and the driving system 2 , the second multi-channel valve 6, the third multi-channel valve 7, the first multi-channel valve 5 and the power battery 1 form a first heating circuit; the battery cooler 4 is connected in parallel to the air-conditioning refrigeration circuit for batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com