Aluminum oxide plant decomposer stirring motor dual-power-supply on-site box power supply method

A technology of stirring motor and alumina plant, which is applied in emergency power supply arrangement, AC motor control, control of multiple AC motors, etc., can solve the problems of inability to supply power to the stirring motor of the decomposition tank, unable to supply power to the stirring motor of the decomposition tank, etc., to achieve flexibility. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

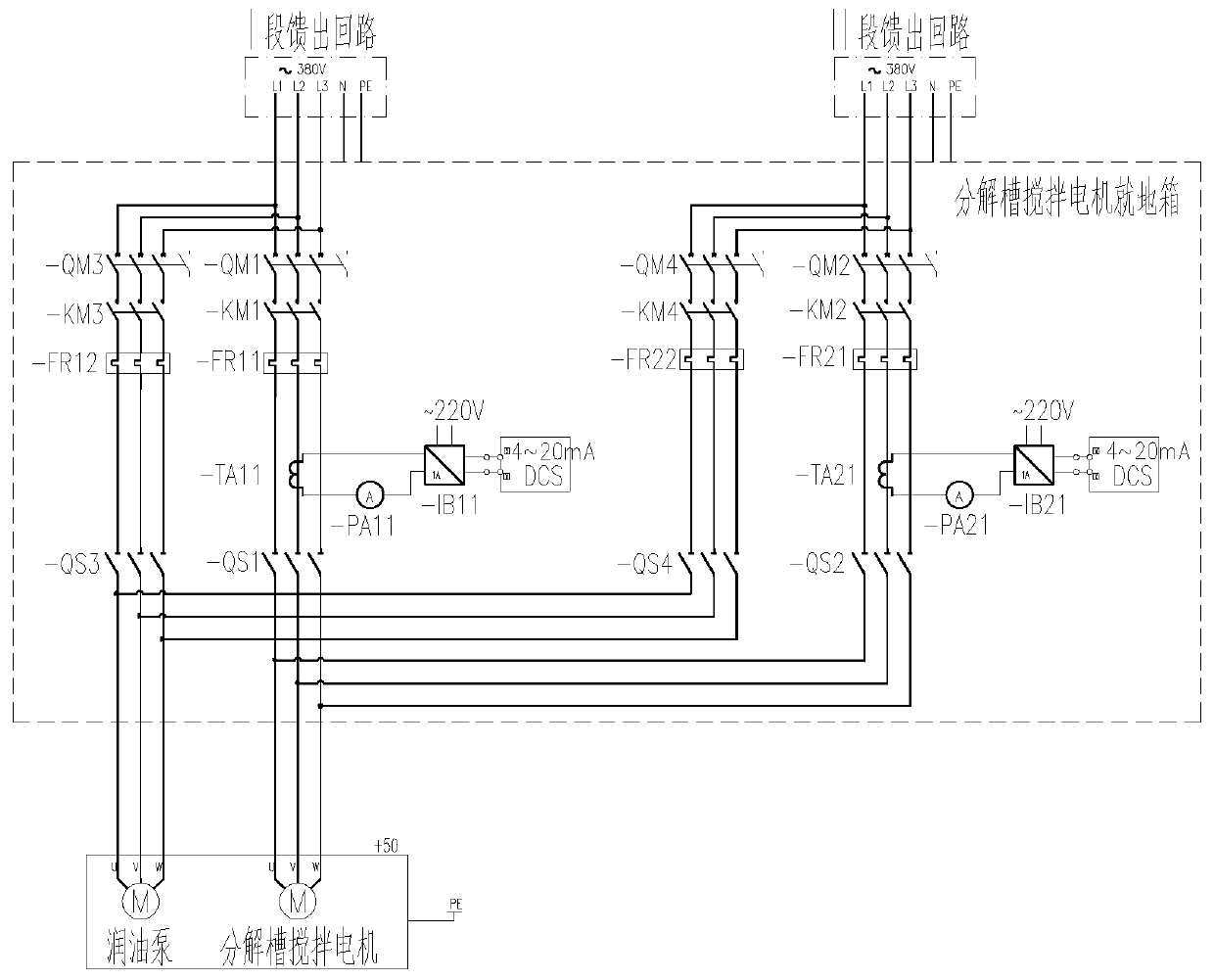

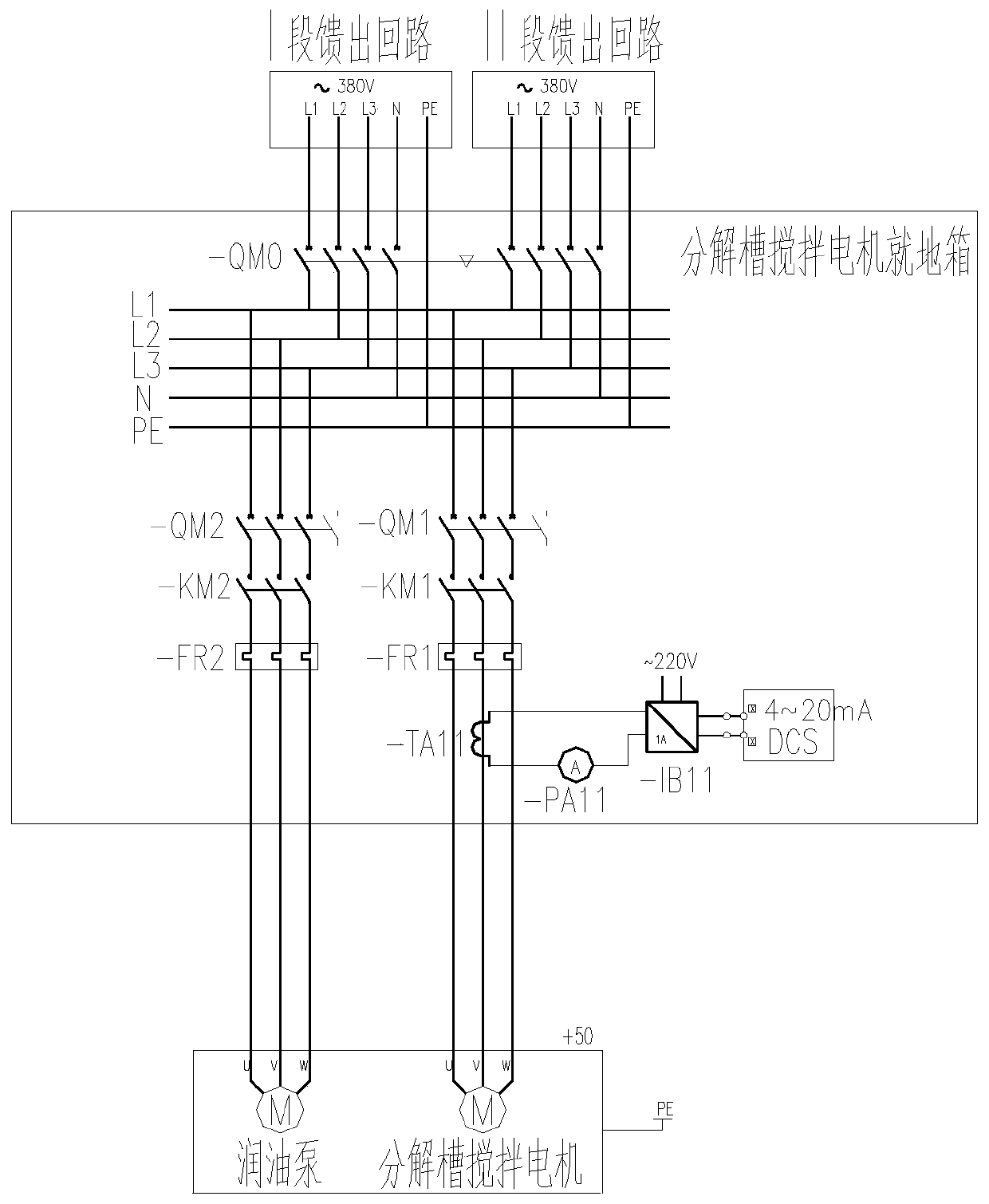

[0018] Decomposition tank mixing motor dual power supply on-site box can be modified from an outdoor anti-corrosion power box. The overall dimensions of the box are 1000 wide, 400 deep, and 1200 high. The lower part is fixed and installed with No. 8 channel steel. .

[0019] The internal electrical components are: QM1 to QM4 automatic switch, KM1 to KM4 contactor, FR11, FR21, FR12, FR22 thermal relay, QS1 to QS4 isolating knife switch, TA11, TA21 single-phase current transformer, PA11, PA21 ammeter, IB11, IB21 current transmitter, etc. All of the above can be selected according to the power of the decomposition tank stirring motor and lubricating oil pump. For details, see "Industrial and Civil Power Distribution Design Manual". It is a standard design. The electrical components are standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com