Novel aluminum alloy profile tailor-welded side wall structure and assembly welding process thereof

A technology of aluminum alloy profiles and side wall structures, applied in metal processing, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of waste of profile materials, complicated process, high cost, etc., to ensure welding quality and economy Strong, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

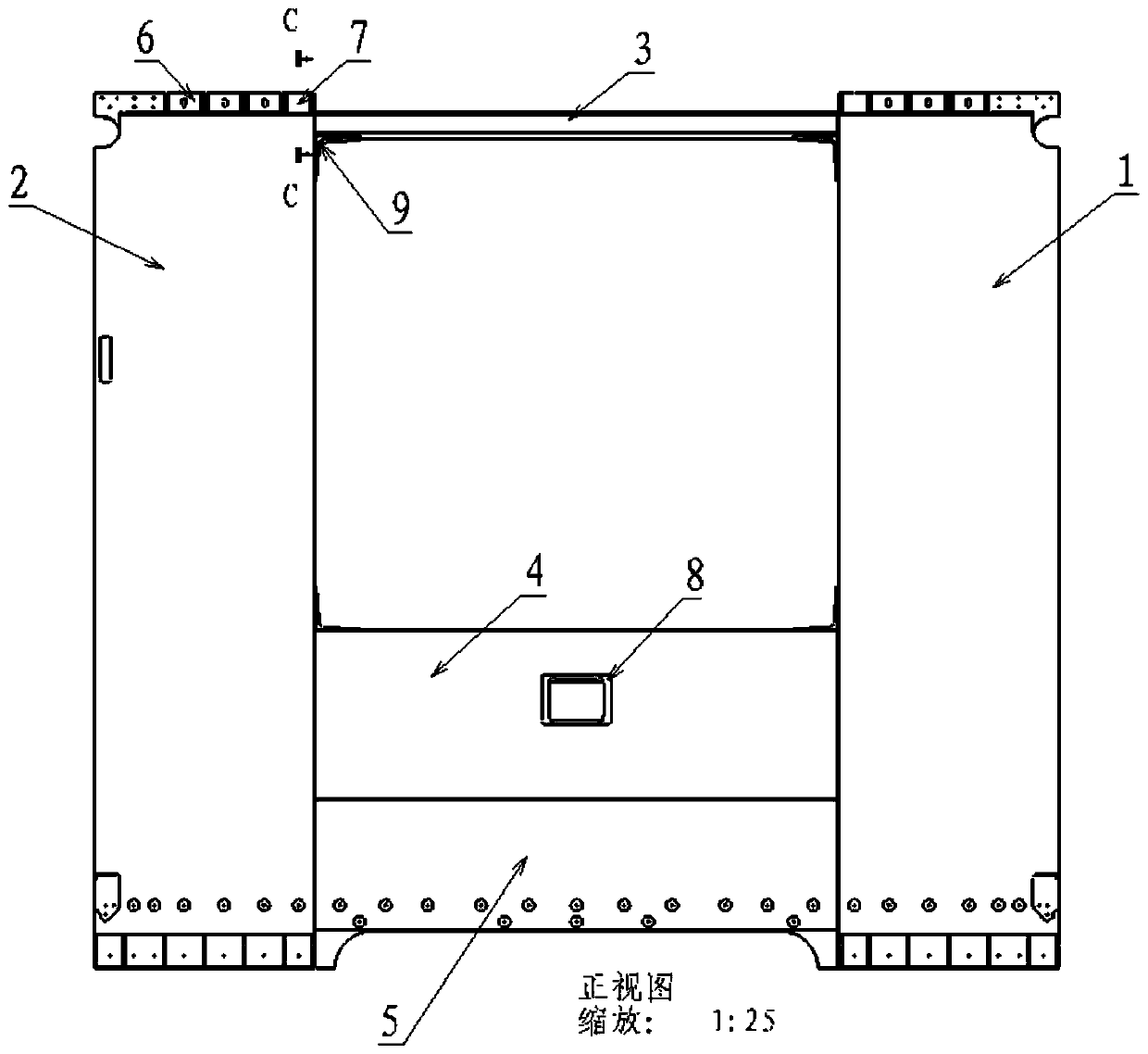

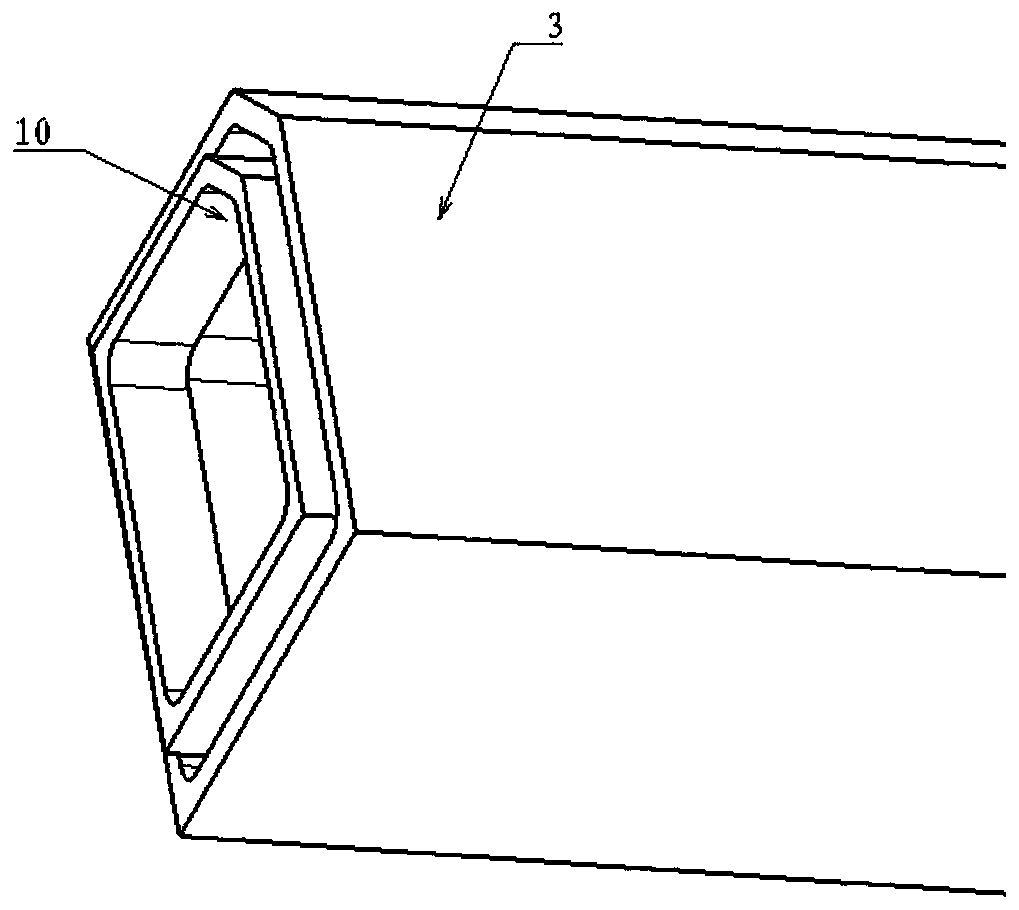

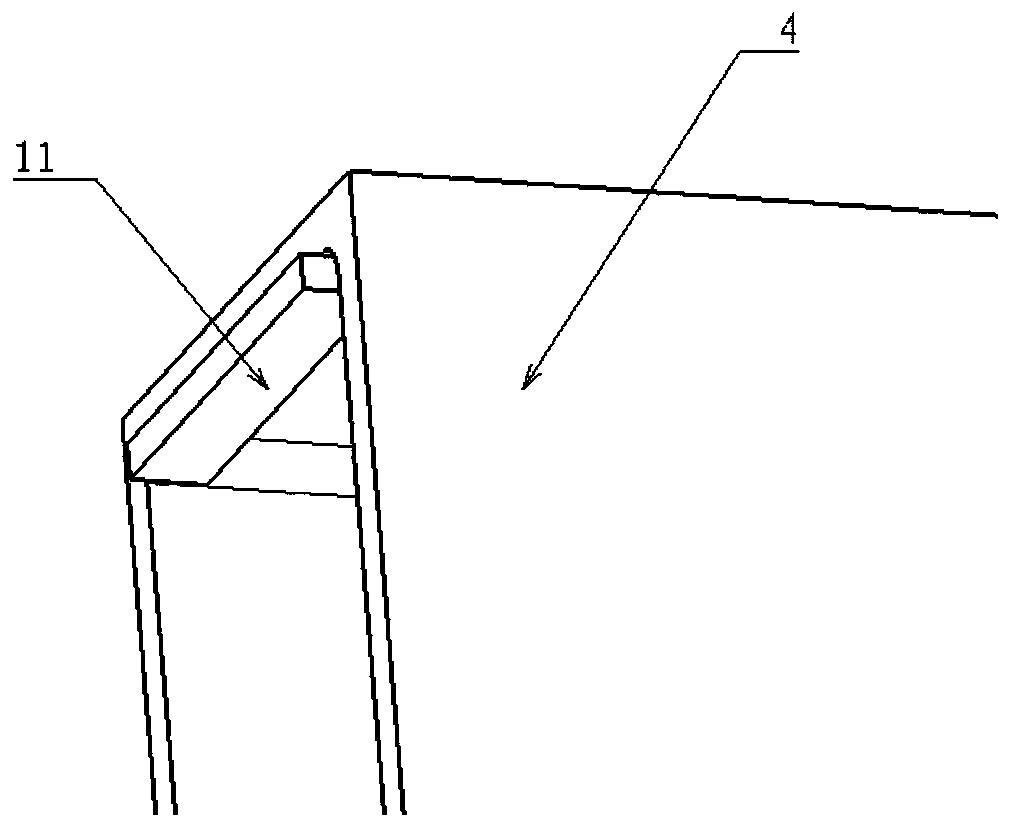

[0031] Such as figure 1 The side wall structure of the new aluminum alloy profile tailor welding shown is made of multiple aluminum alloy profile tailor welding, including the first column 1, the second column 2, the upper part of the window frame 3, the upper panel 4, the lower panel 5, The backing plate 6, the bending backing plate 7 and the mounting plate 8, the first column 1 and the second column 2 are vertically arranged on both sides of the side wall structure, and the upper part of the window frame 3 and the upper panel are arranged horizontally between the two 4 and the lower panel 5, a window is provided between the upper part of the window frame 3 and the upper panel 4 for later installation of the window frame, the upper panel 4 and the lower panel 5 are connected and welded to each other, and the upper panel 4 is provided with a square hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com