Handset silkscreen butt pasting machine

A wire mesh and earpiece technology, applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of human error, safe operation, and low rate of good products, and achieve improved controllability, convenient installation and debugging, and convenient and effective return. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

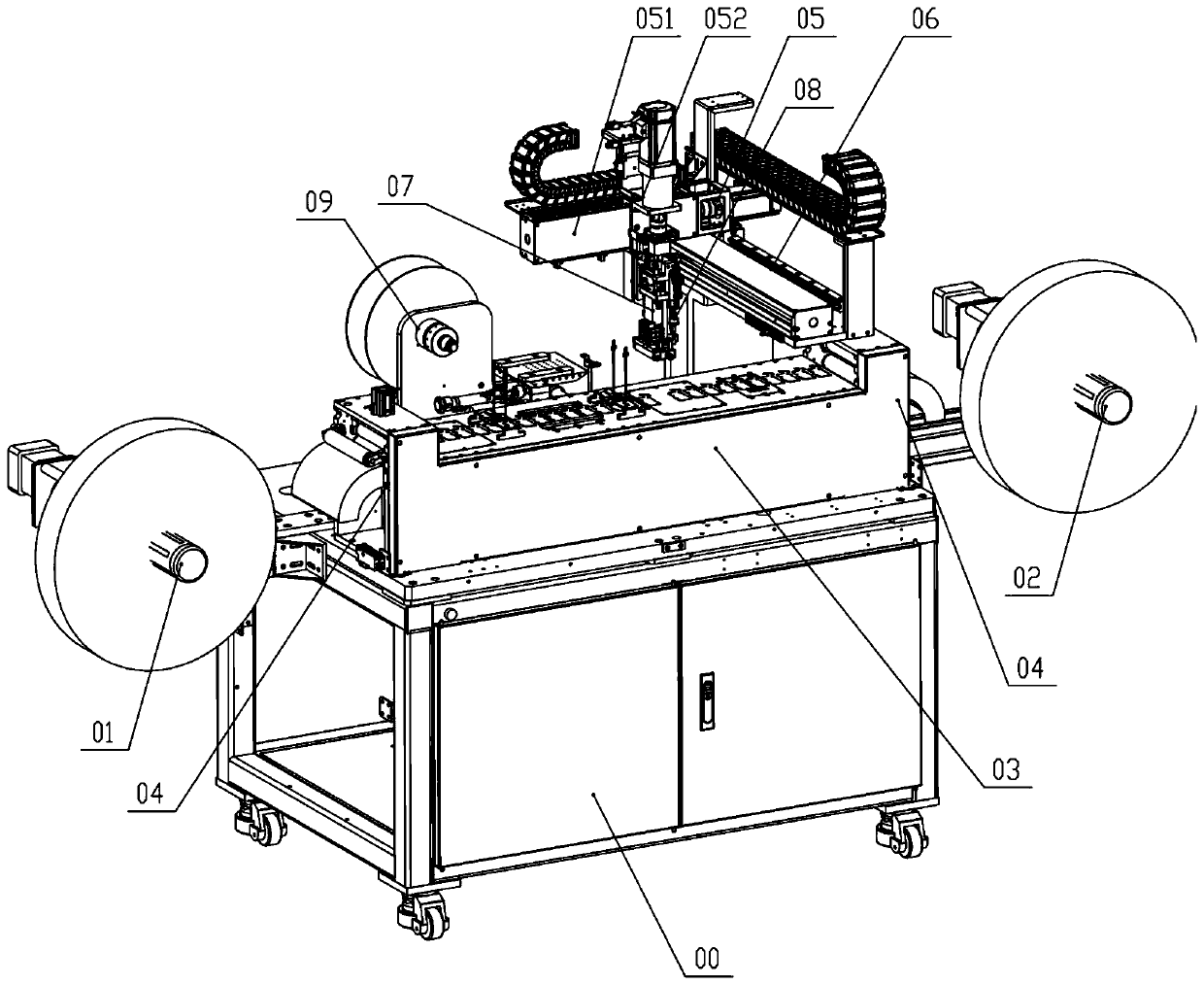

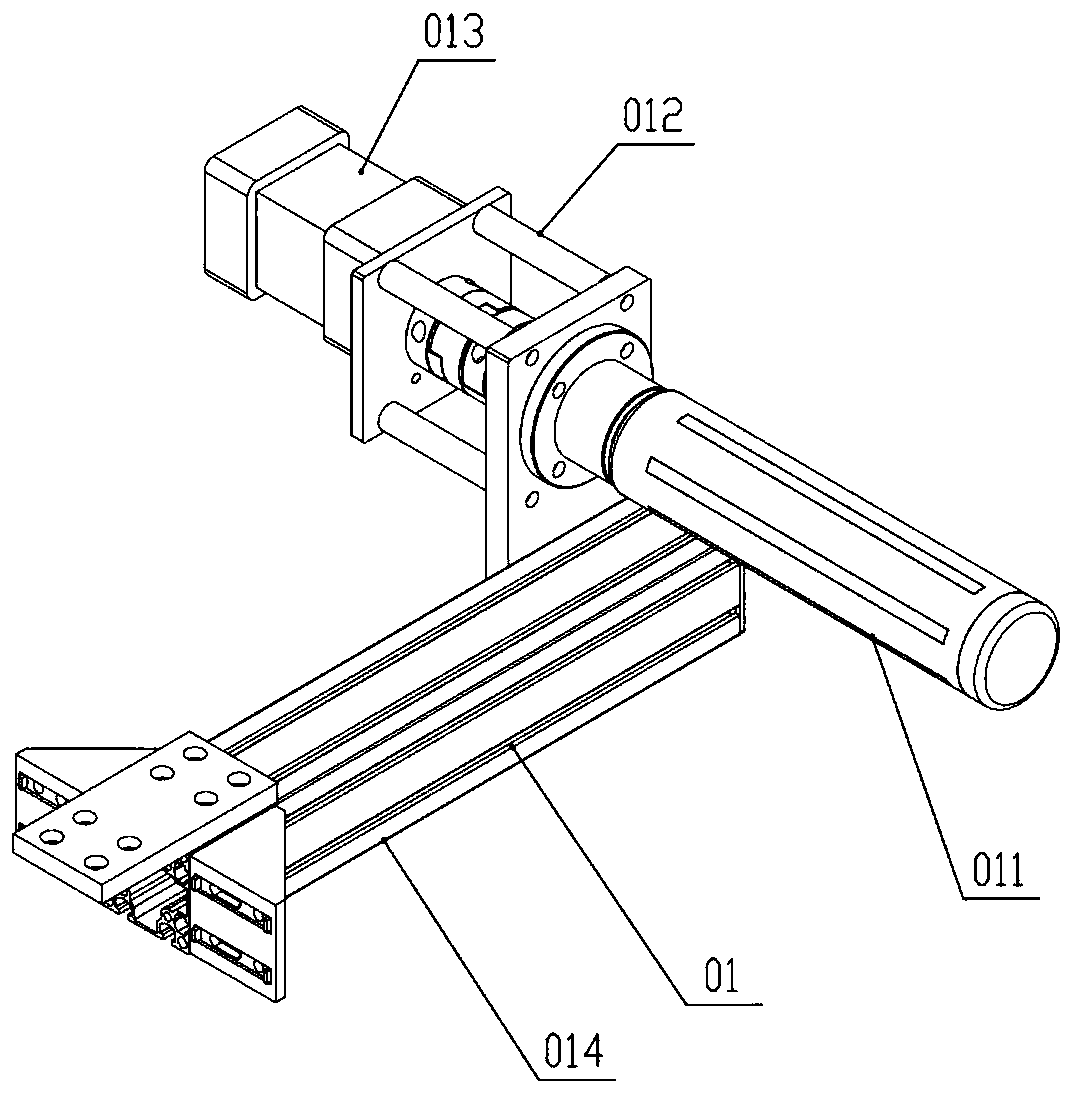

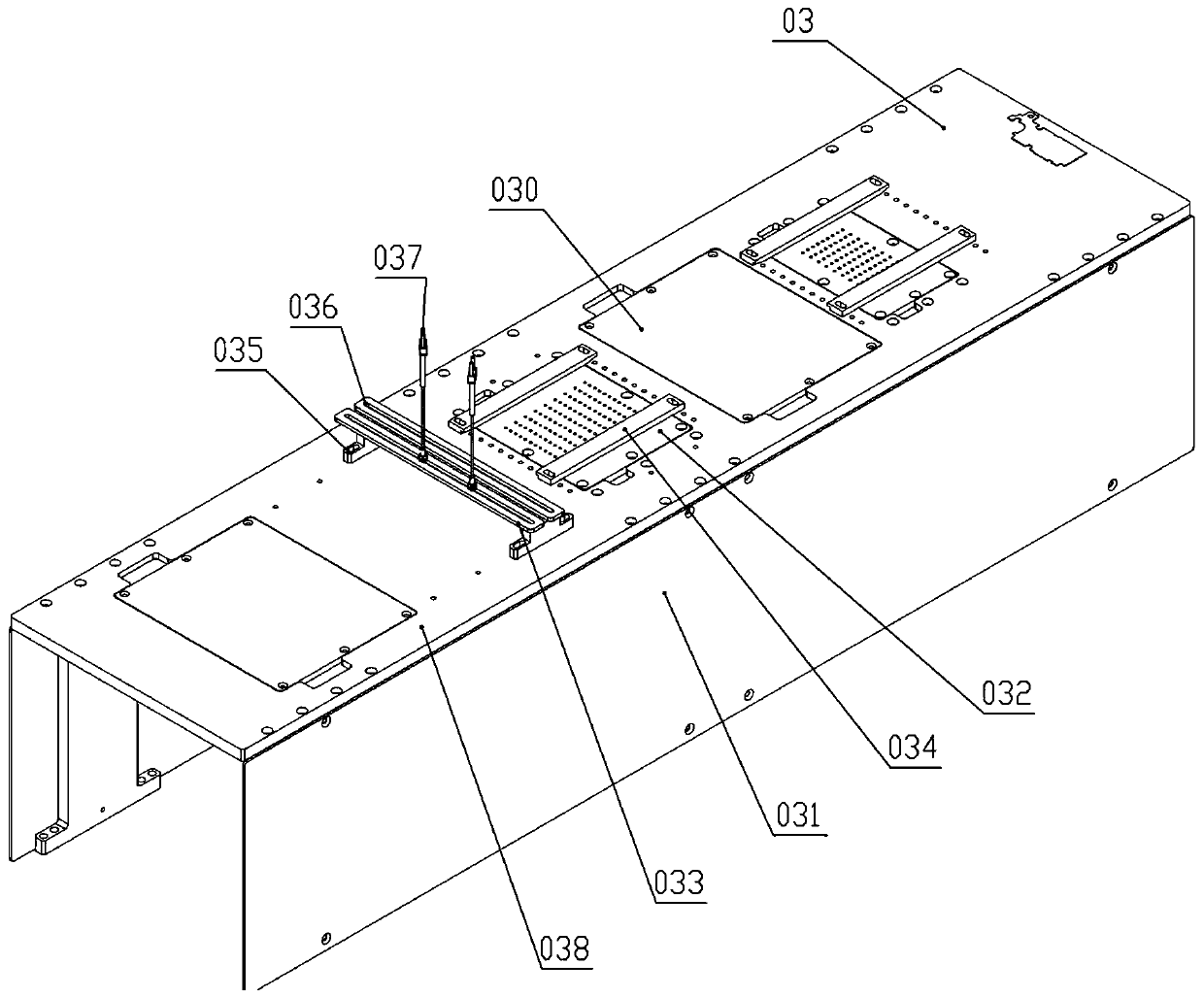

[0059] Figure 1 to Figure 18 It schematically shows an earpiece screen bonding machine according to an embodiment of the present invention. As shown in the figure, the device includes a frame 00, the left end of the frame 00 is equipped with a discharge module 01 and the right end is equipped with a material receiving module 02, the front end of the frame 00 is equipped with a reposting station 03, and the upper rear end of the frame 00 is installed on the left side. The stripping machine 09 is equipped with a four-axis manipulator 05 on the right side, and the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com