Stove burner

A technology for burners and cookers, which is applied in the field of cookers, can solve problems such as limited secondary air area, and achieve the effects of simple structure, good heat dissipation effect and strong ejection ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

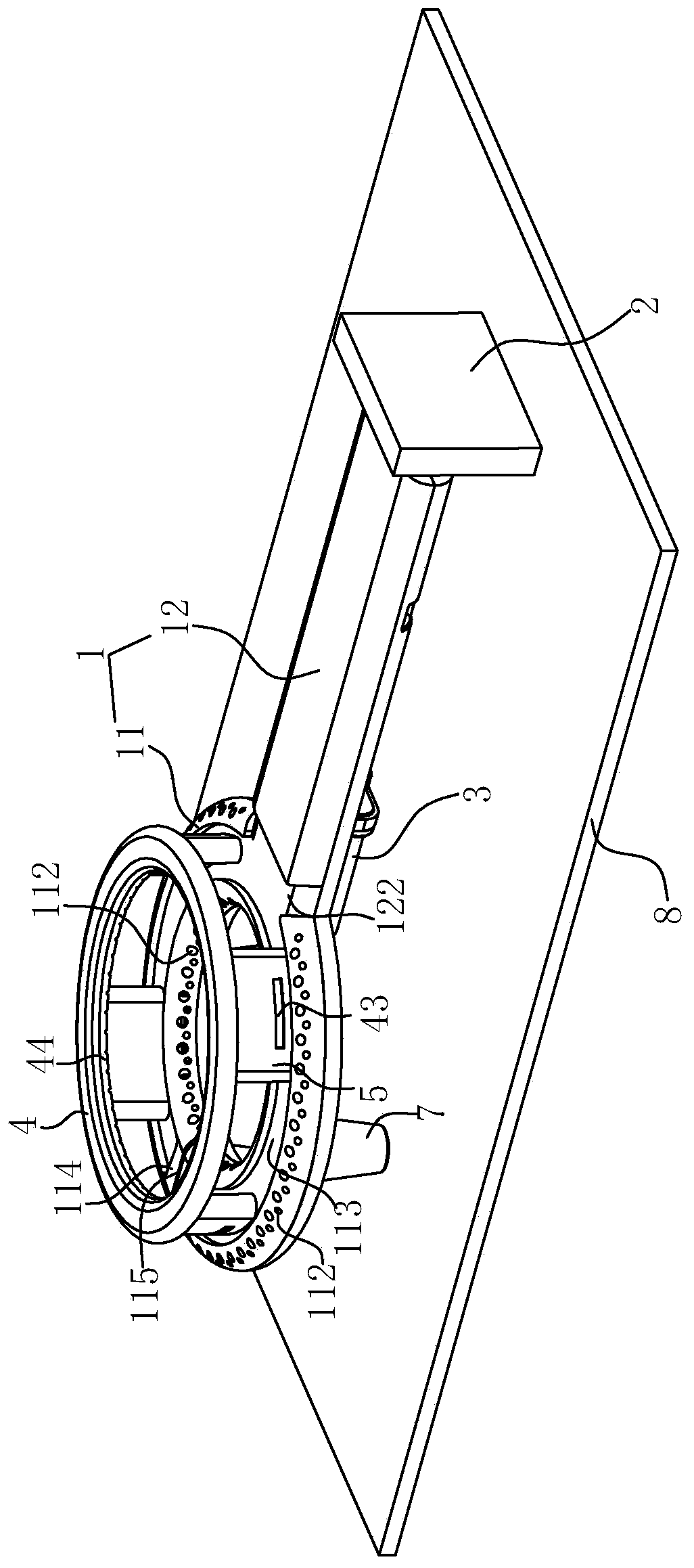

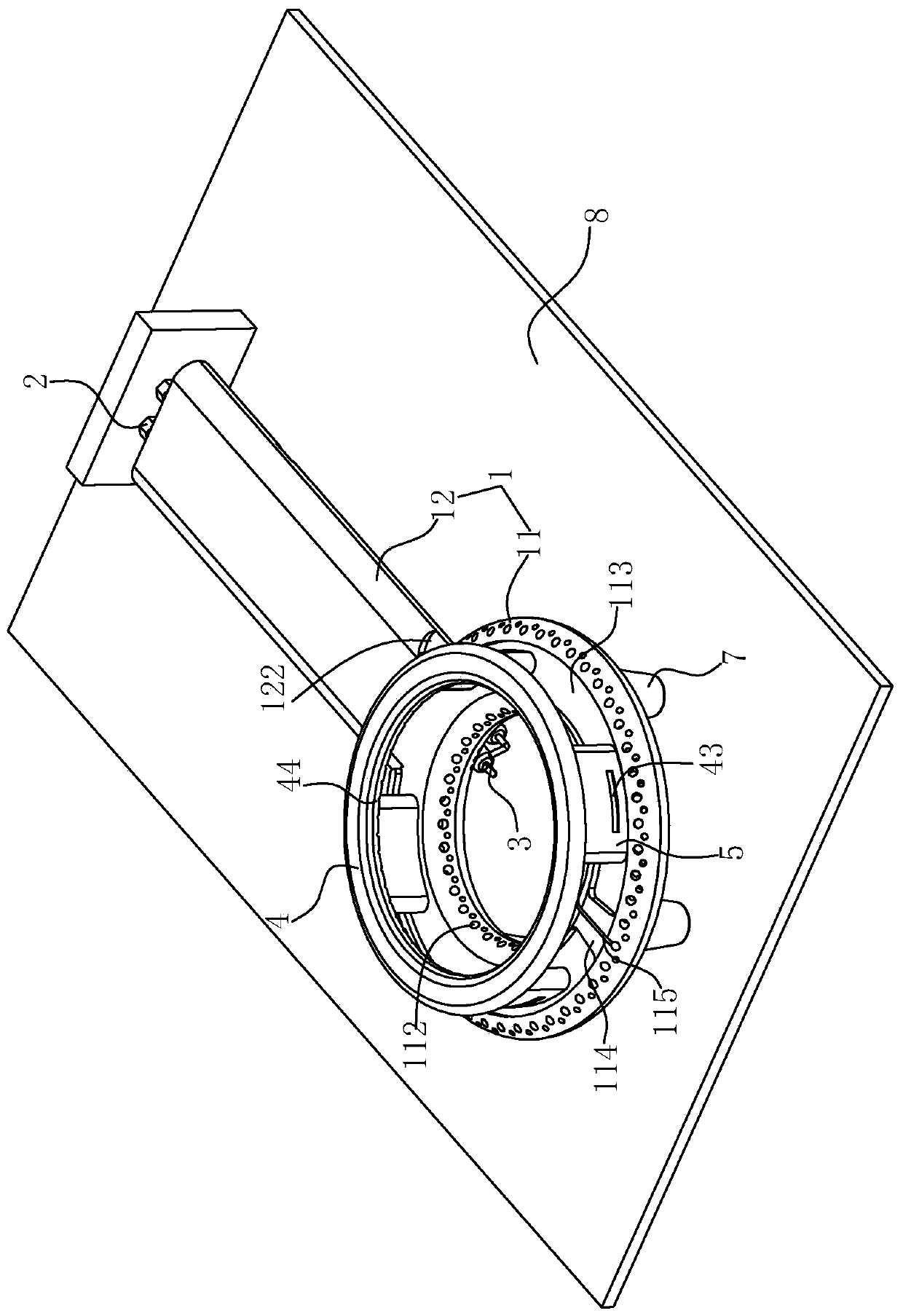

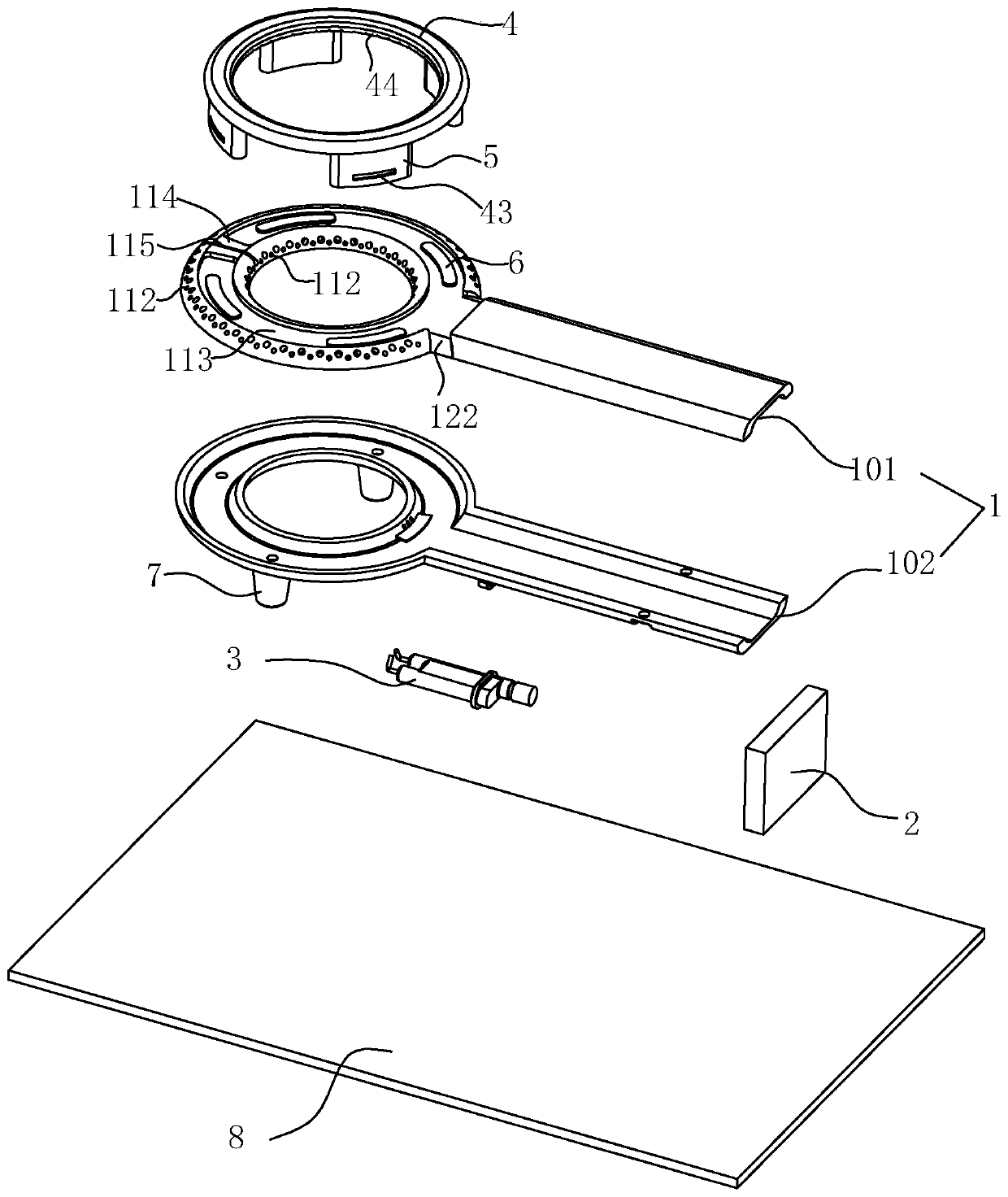

[0036] Such as Figure 1 to Figure 5 As shown, a cooker burner in this embodiment includes a base 1 , a nozzle 2 , an ignition pin 3 , and a pot support 4 .

[0037] Wherein the base body 1 has the gas mixing part 11 and the injection part 12 which are connected and arranged horizontally. According to the structural requirements, the gas mixing part 11 and the injection part 12 of the base body 1 are integrally connected or separately connected. When the gas mixing part of the base body 1 11 and the injection part 12 are integrally connected, the structure is simple, the installation is convenient, and the sealing of the structure is excellent. However, the gas mixing part 11 and the injection part 12 connected separately can reduce the packaging volume during packaging and facilitate transportation.

[0038] The substrate 1 in this embodime...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap