Method and test device for mechanically controlling object surface/interface adhesion strength

A technology of interface adhesion and test device, applied in the direction of using mechanical devices, measuring devices, viscosity control, etc., can solve the problems of high pre-pressure, poor versatility, and no benefit to human beings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

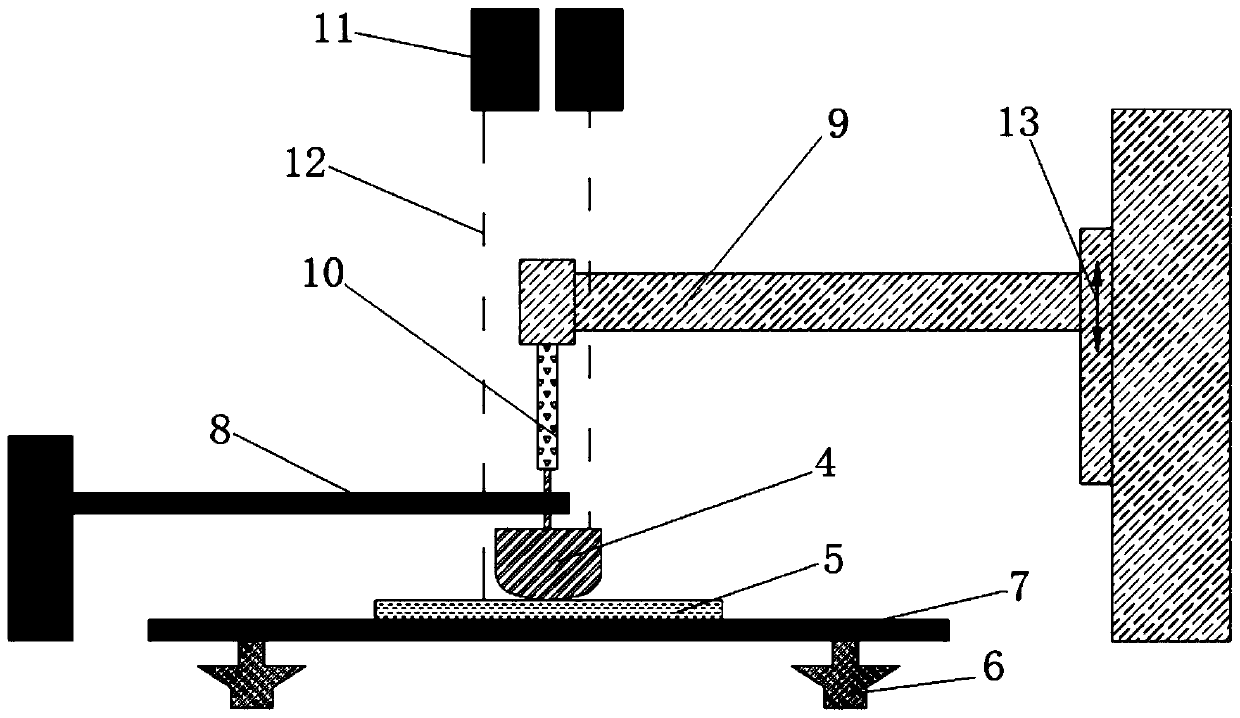

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

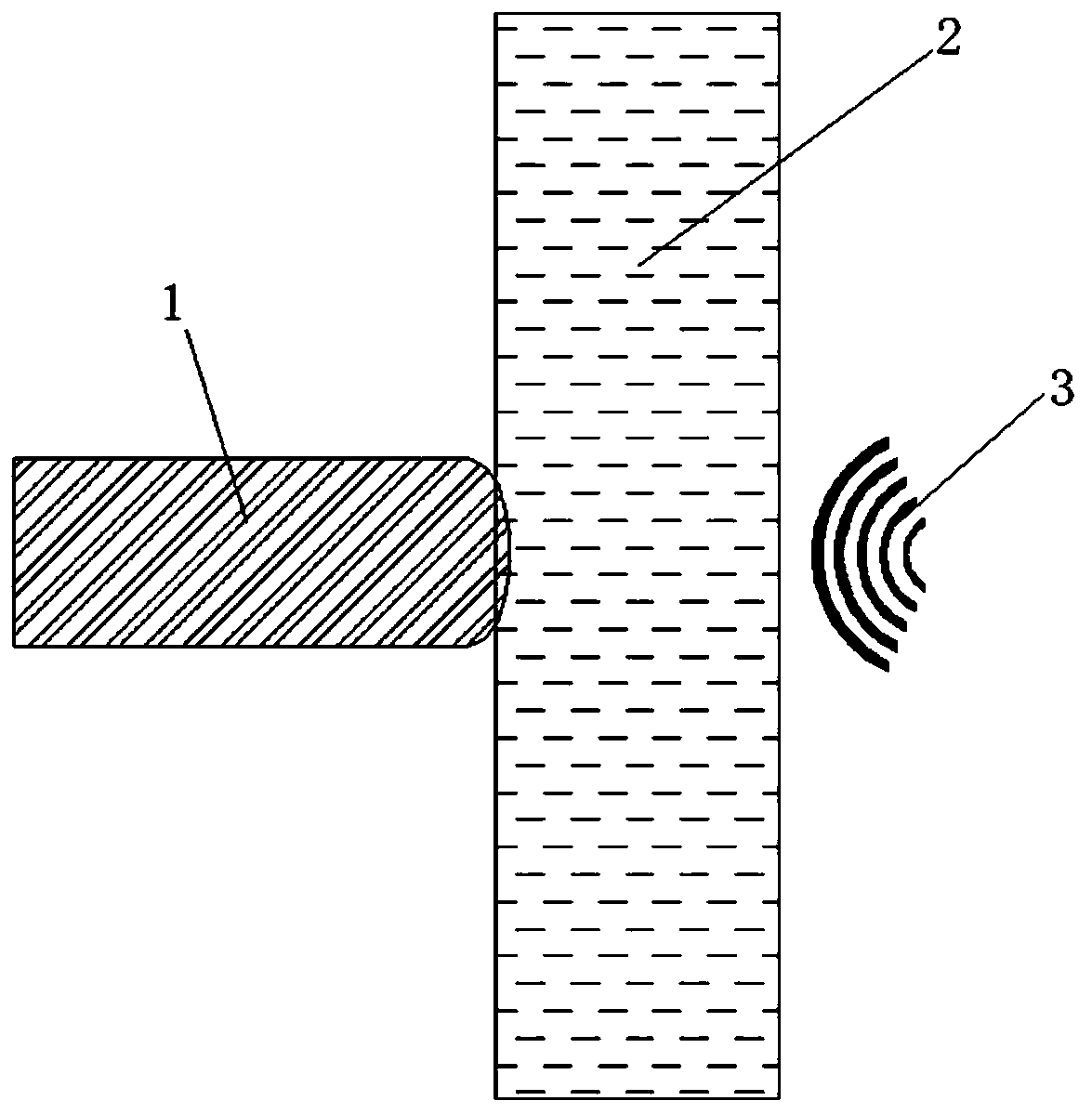

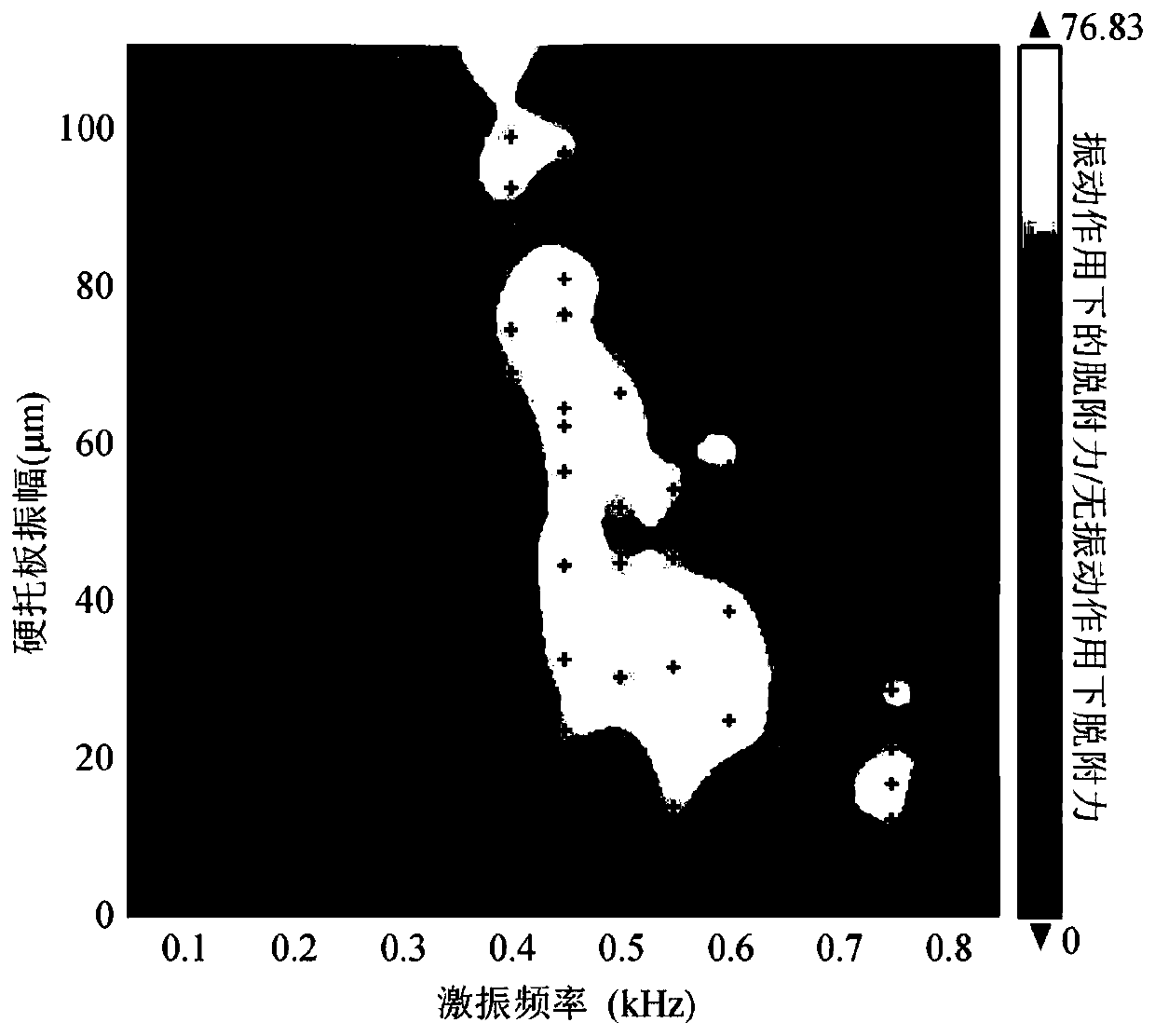

[0024] A method of mechanically regulating the surface / interface adhesion strength of an object. On the premise of not relying on the microstructure of the object surface, the surfaces of two sticky objects are brought into contact to form a contact pair (such as figure 1 The surfaces of object 1 and object 2 are in contact together to form a contact pair), and the two objects in the contact pair are excited to perform relative mechanical vibration, so that the contact area of the contact pair changes with time, and the object is regulated by changing the excitation frequency or amplitude Surface / interface adhesion strength.

[0025] The definition of adhesion strength includes not only the real strength—the ratio of the interface contact force to the real contact area, but also the apparent strength—the interface contact force and a certain character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com