automatic conditioning machine

A cooking machine and automatic technology, which is applied to cooking utensils, timing control ignition mechanisms, cooking utensil lids, etc., can solve the problems of high personnel turnover in the catering industry and difficulty in improving the catering industry, so as to improve cooking efficiency and avoid The effect of wasting food and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The embodiments of the present invention will be described below with reference to the related drawings. In the drawings, the same reference numbers refer to the same or similar elements or method flows.

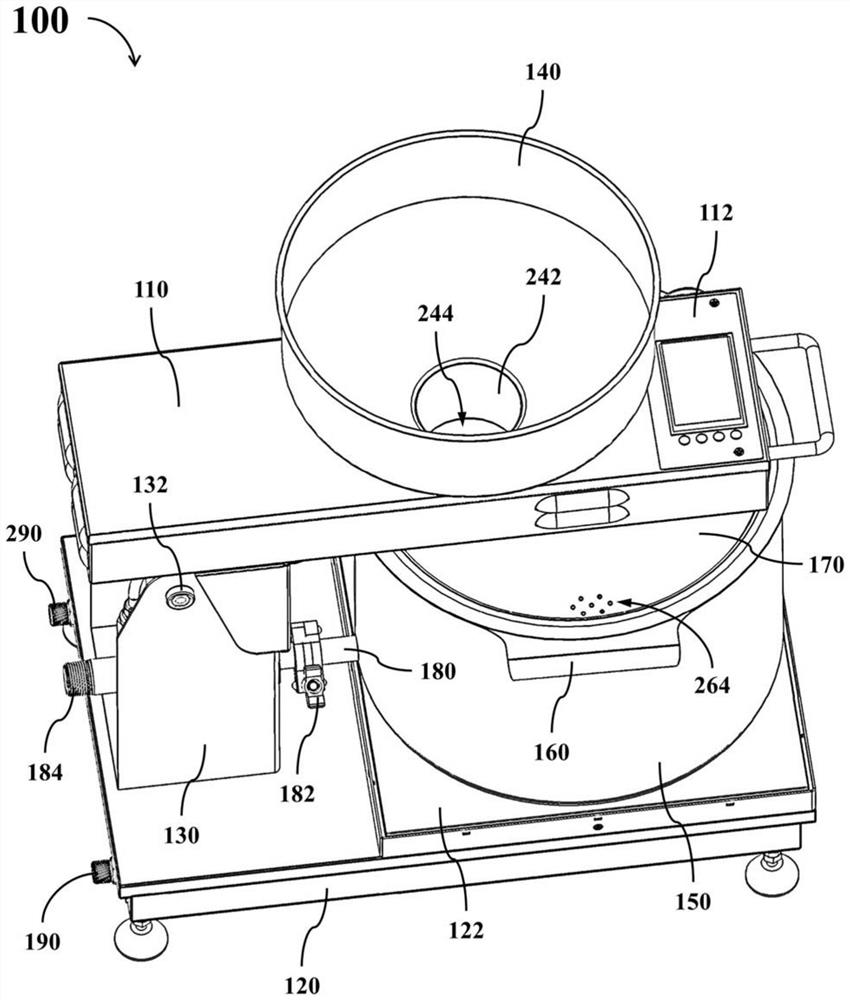

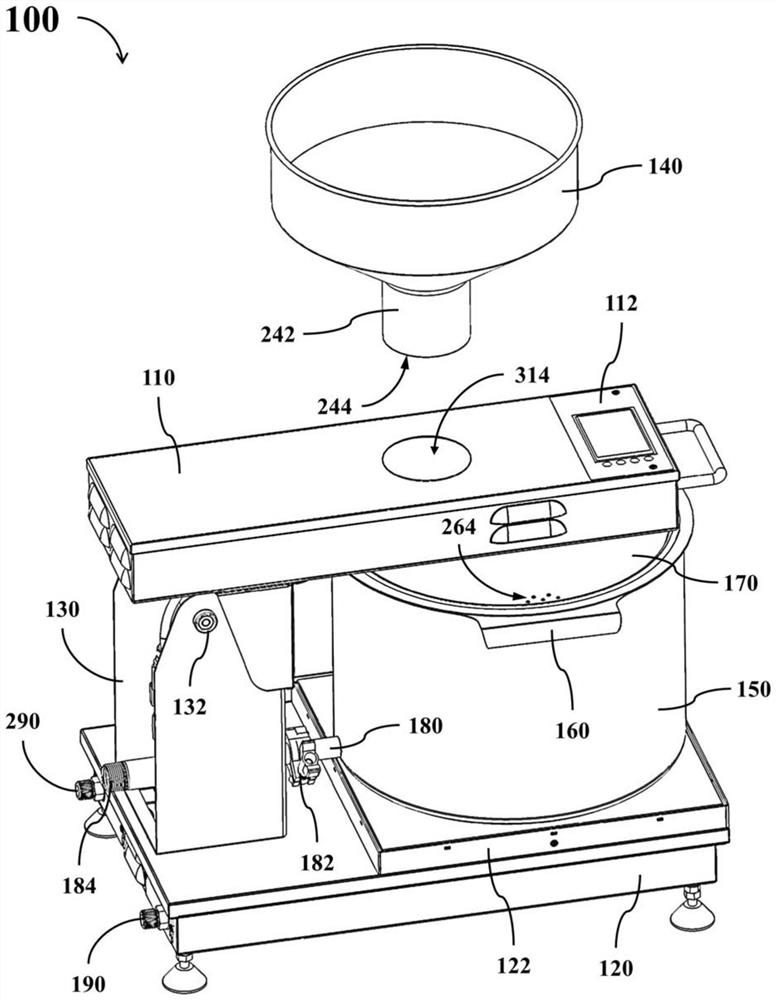

[0085] Please refer to Figure 1 to Figure 3 . figure 1 and figure 2 It is a simplified schematic diagram of the appearance of the automatic conditioning machine 100 from different viewing angles according to an embodiment of the present invention. image 3 It is a schematic view of the appearance of the automatic conditioner 100 of the present invention when the feeder 140 is separated. The automatic cooking machine 100 can provide the function of automatically controlling the cooking process of the ingredients.

[0086] like Figure 1 to Figure 3 As shown, the automatic conditioner 100 includes a top 110 , a base 120 , a support 130 , a pivot 132 , a heater 122 , a feeder 140 , a cooking pot 150 , a colander 160 , a lid 170 , a drain 180 , and a drain 184 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com