Equipotential control device and method for plasma heating of continuous casting tundish

A continuous casting tundish and control device technology, which is applied to casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of difficult to ensure the stability of molten metal temperature, and achieve the effect of ensuring heating, ensuring stability, and ensuring effective changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

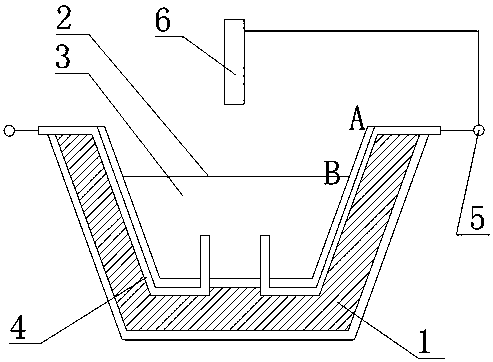

[0028] Such as figure 1 As shown, an equipotential control device for plasma heating of a continuous casting tundish, the device is controlled by a PLC control system, the tundish 1 contains a slag layer 2 and molten steel 3, including pre-buried between the refractory material layers of the tundish 1 The steel wire 4 is connected to the zero potential sampling point of the PLC control system. One end of the steel wire 4 leaks about 3~5mm from the bottom of the tundish 1, and the other end of the steel wire 4 is connected to a galvanized round steel 5. And it is reliably connected with the shell of the tundish 1, the galvanized round steel 5 is connected with an insulated flexible wire, the insulated flexible wire is connected with an electrode 6, the electrode 6 is installed on the lifting device, and the PLC control system is connected to and controls the lifting device.

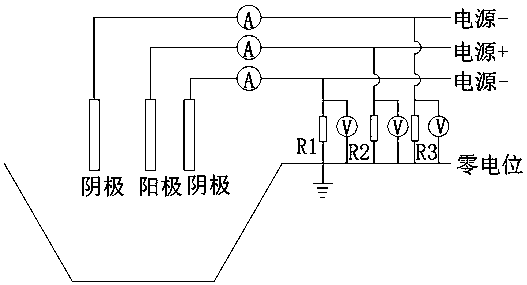

[0029] The electrode 6 includes an anode and a cathode. The electrode 6 is connected to an external pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com