On-line monitoring system for noise and vibration of transformer

A technology for monitoring systems and transformers, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems such as errors, impact of diagnostic results, mechanical failures, and control circuit failures that cannot be reflected in time, and achieve comprehensive monitoring and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

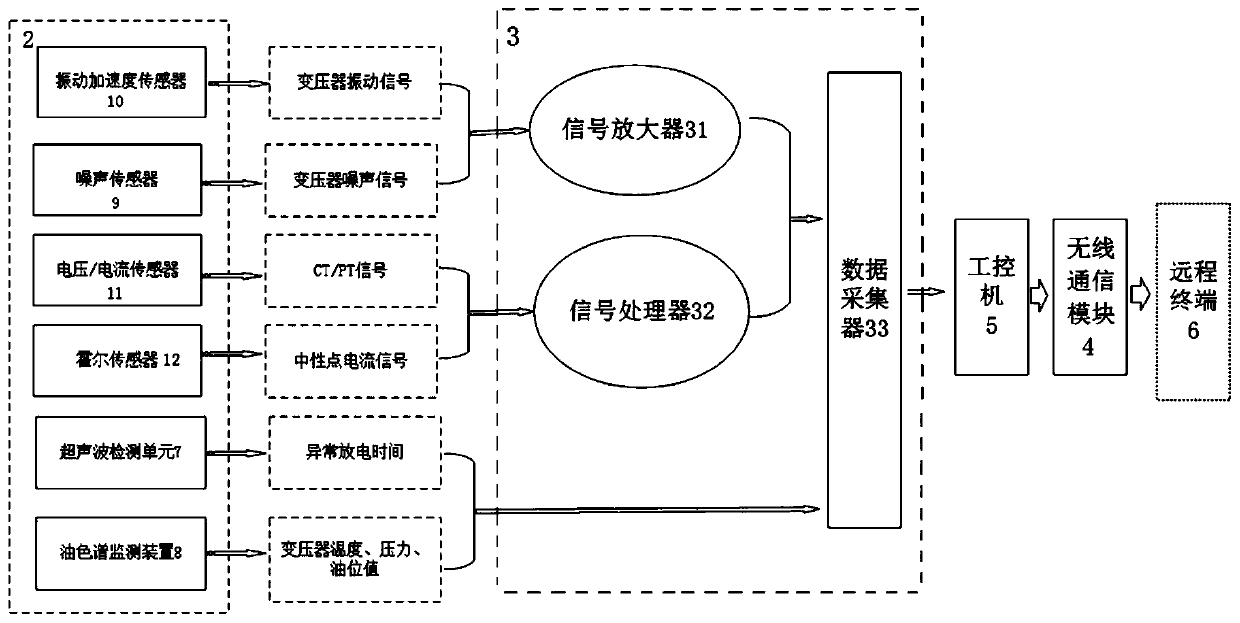

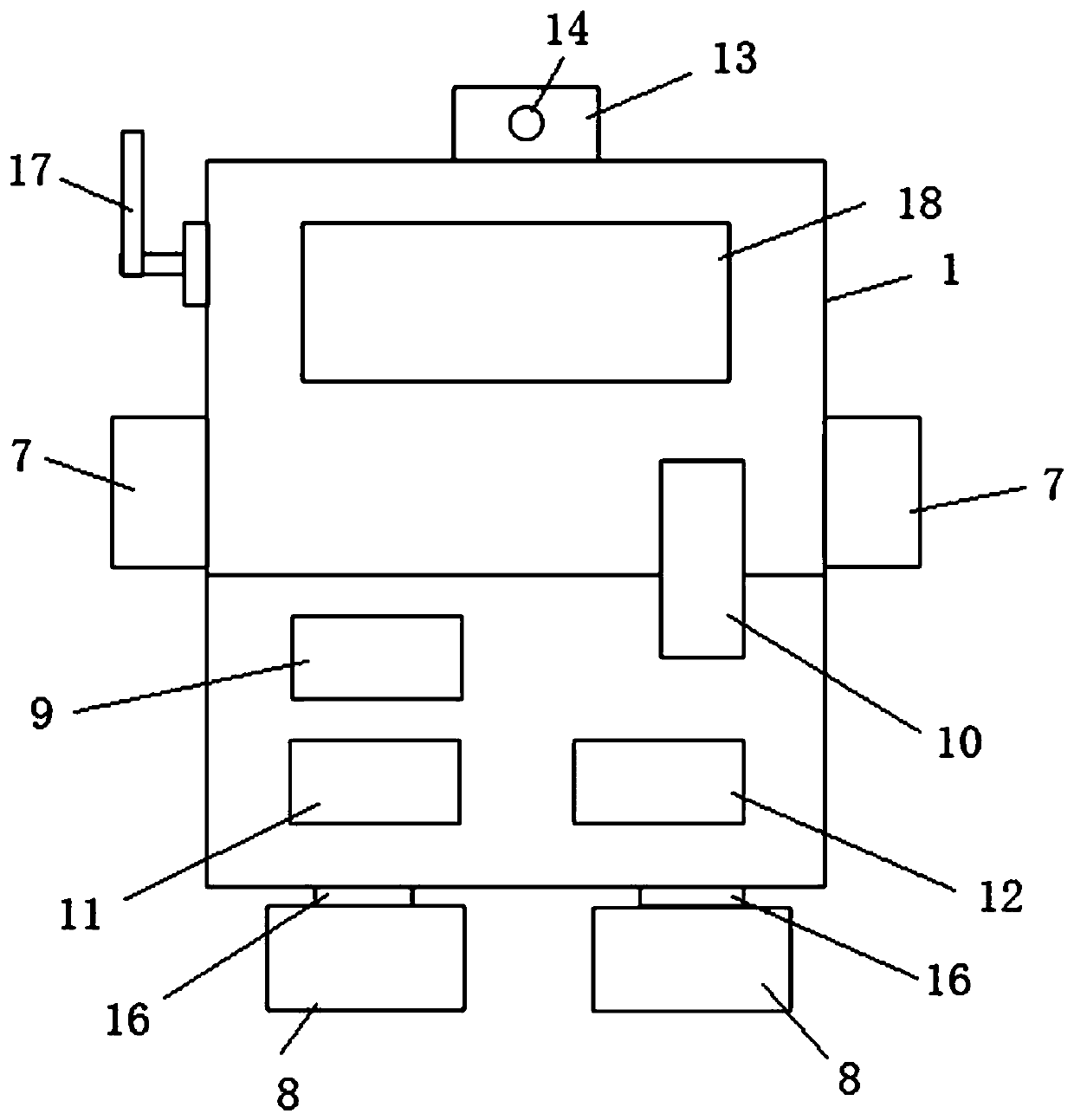

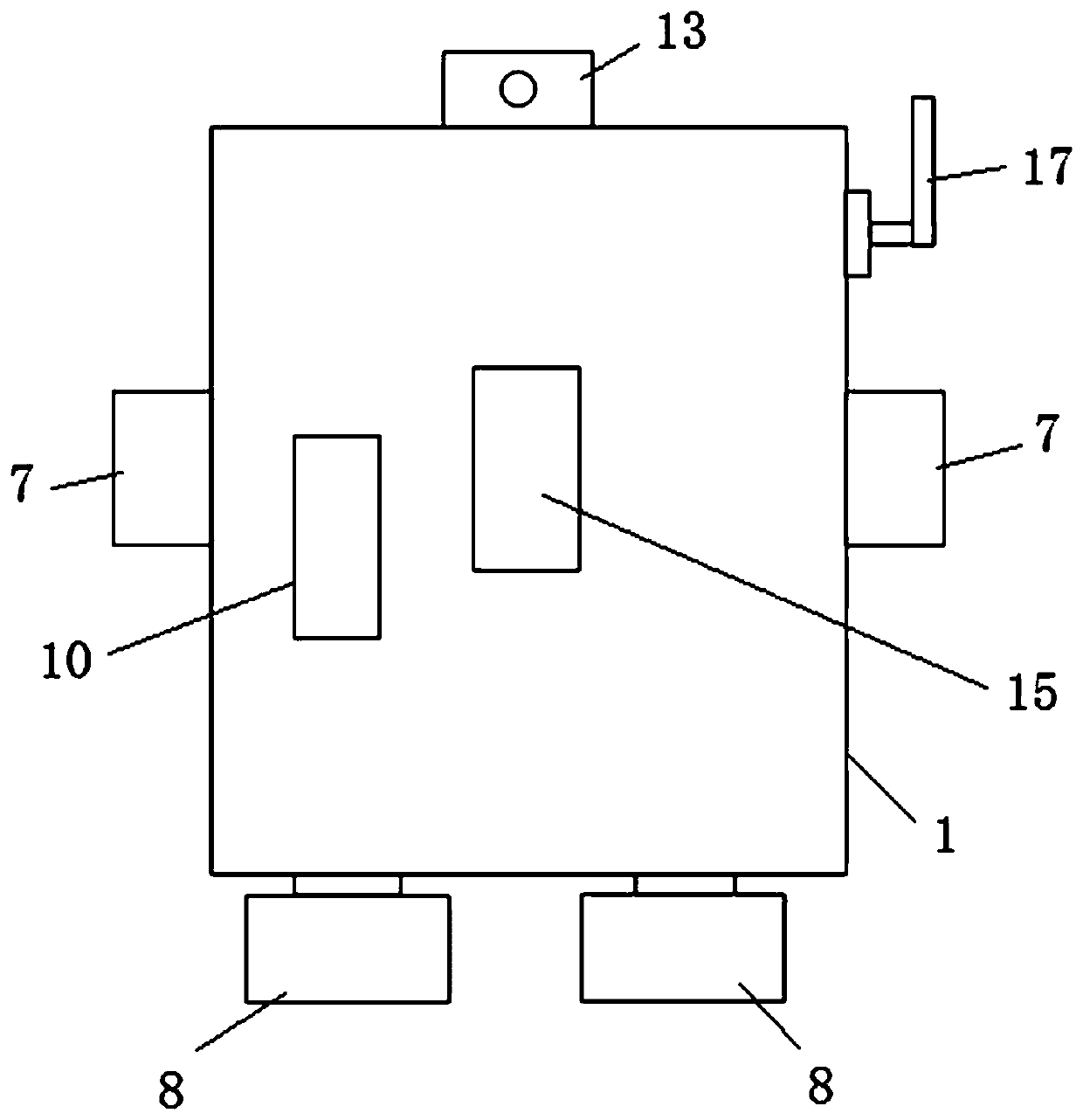

[0038] The invention relates to an online transformer noise and vibration monitoring system, which includes a transformer signal acquisition module 2 , a data acquisition module 3 , a wireless communication module 4 , an industrial computer 5 and a remote terminal 6 . The transformer signal acquisition module 2 is concentrated on a box body 1 . The data acquisition module 3 and the industrial computer 5 are arranged in the box body 1 . The transformer signal acquisition module 2 is connected to the data acquisition module 3 , the data acquisition module 3 is connected to the industrial computer 5 , and the industrial computer 5 is connected to the remote terminal 6 through the wireless communication module 4 .

[0039] Such as figure 2 As shown, the transformer signal acquisition module 2 includes an ultrasonic detection unit 7 , an oil chromatography monitoring device 8 , a noise sensor 9 , a vibration acceleration sensor 10 , a voltage / current sensor 11 , and a Hall sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com