Double-sided double-arc back-gouging-free welding method of Q460 corrosion-resistant and fire-resistant steel plates

A double-sided, double-arc, welding method technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as smoke, dust pollution, reduced welding efficiency, and increased heat-affected zone width, so as to improve comprehensiveness, Balance the distribution of heat sources and reduce the effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

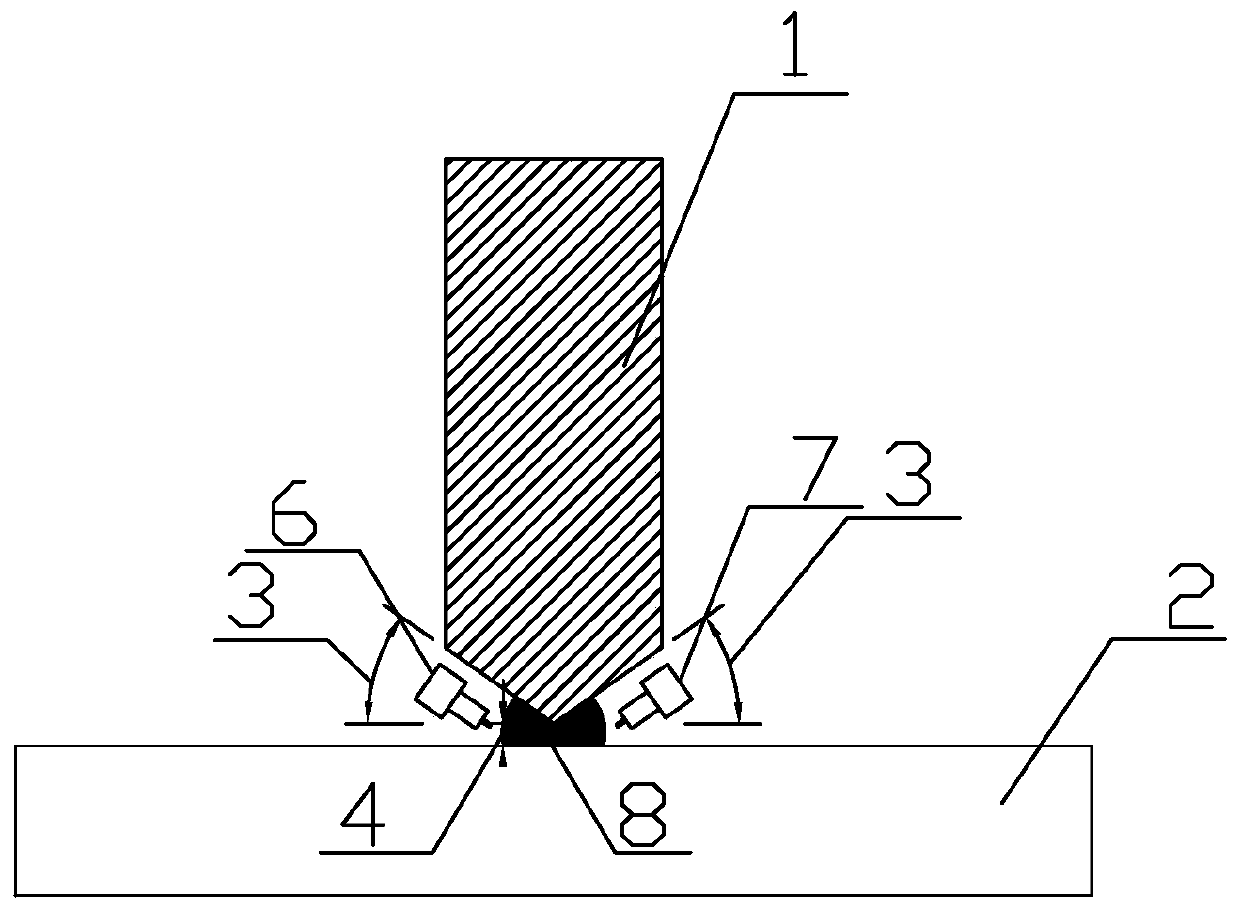

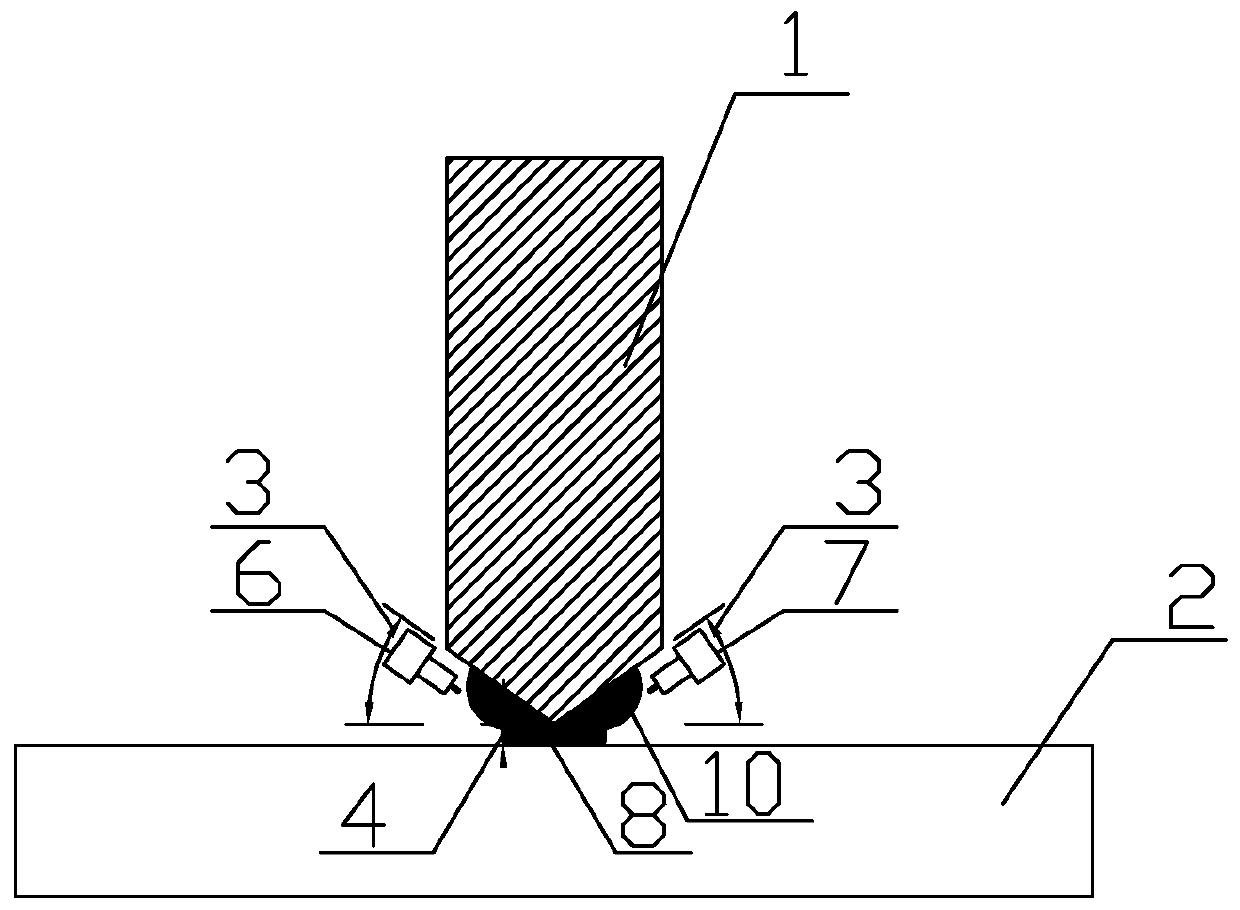

[0025] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1-5 As shown, what the present invention discloses is a double-sided double-arc welding method for Q460 corrosion-resistant and refractory steel plates, so that the welding process of SQ460FRW steel plates can be as much as possible while ensuring the welding quality. Shorten the welding time, reduce the amount of weld deposition, and greatly improve the overall welding efficiency.

[0027] A double-sided double-arc unclear-root welding method for Q460 corrosion-resistant and refractory steel plates, specifically comprising the following steps:

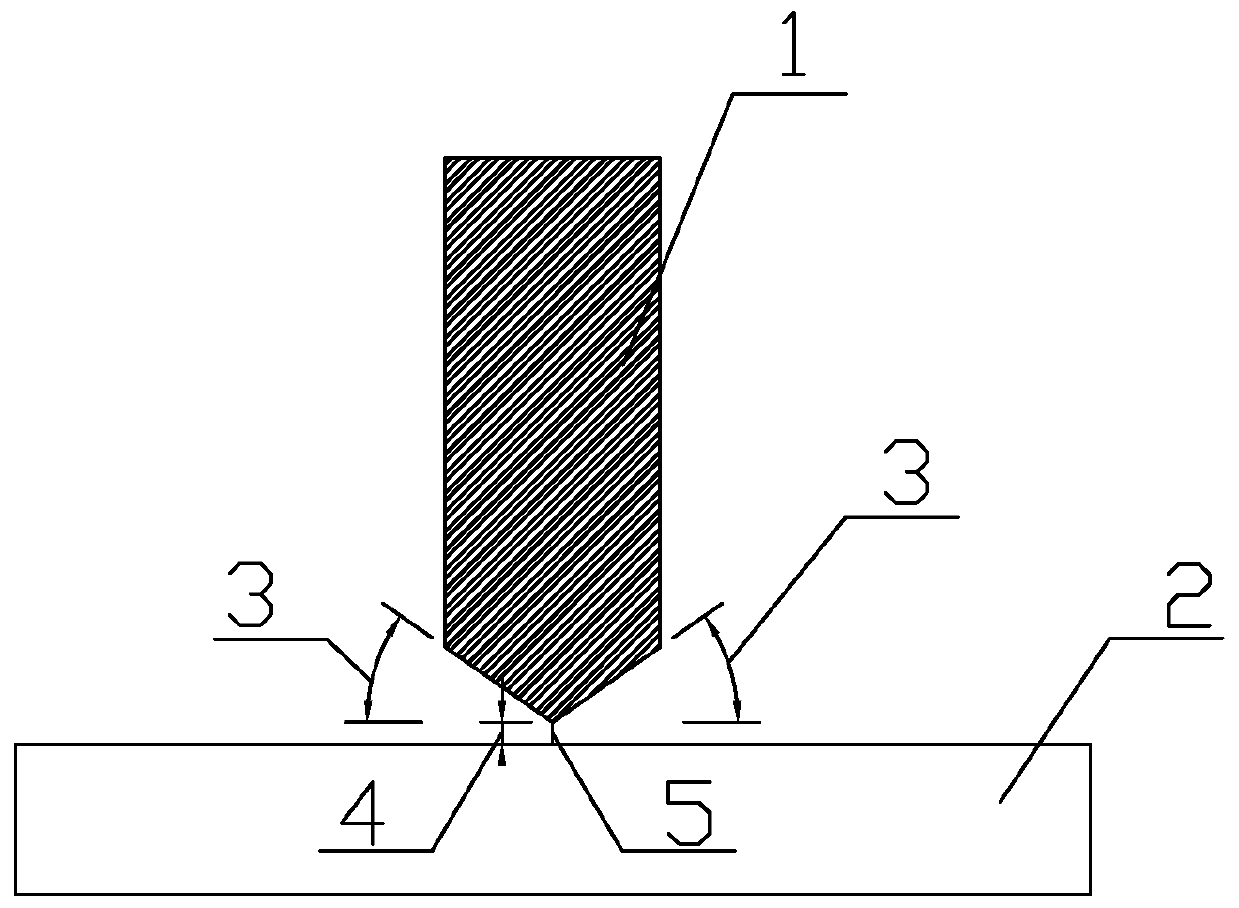

[0028] a), combined figure 1 As shown, the SQ460FRW steel plate is processed into the required vertical plate 1 and horizontal plate 2 to be welded by plasma arc cutting, and the connection end of the vertical plate 1 to be welded is made into a double-sided symme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com