High-alcohol, high-bitterness hop-flavored IPA beer and preparation method thereof

A technology of alcohol content and bitterness, which is applied in the field of hop-flavored IPA beer, which can solve the problems of uncomfortable and stimulating aroma, bitterness and astringency, and achieve the effect of simple and easy-to-operate brewing method, obvious bitterness and high alcohol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

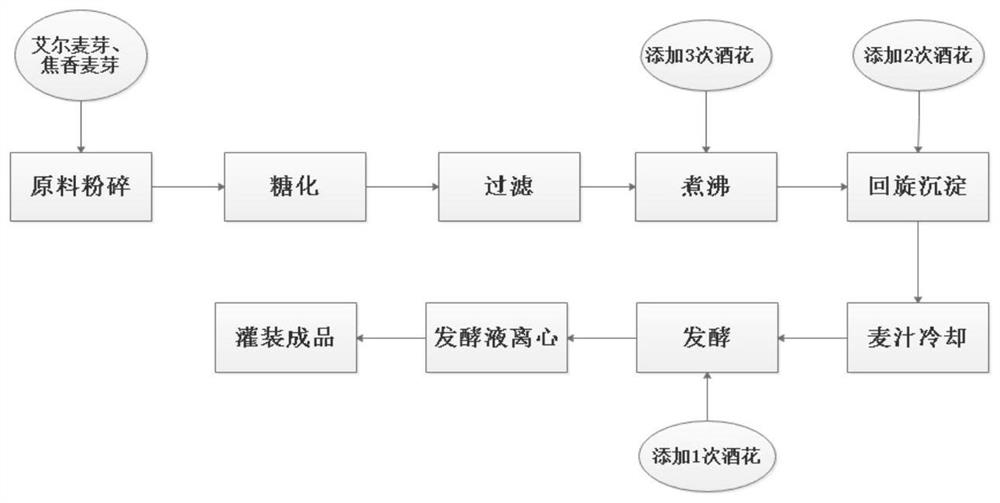

[0033] The embodiment of the present invention also provides a kind of preparation method of hop fragrance IPA beer, comprises the following steps:

[0034] S1: Choose ale malt and caramel malt as the main raw materials. After crushing the raw materials, add them to the mash pot, then add water, and mix them at a ratio of 1:3-1:4. Carry out two-stage saccharification process;

[0035] In the above steps, the ratio of material to water is mixed according to the ratio of 1:3-1:4, wherein the ratio can be selected as 1:3, 1:4 or any value within the limited range; the method of two-stage saccharification is selected. , including the first stage of saccharification at 48-52°C for 20-40 minutes and the second stage of saccharification at 63-68°C for 60-70 minutes. The advantage of the two-stage saccharification method is that it can ensure the full decomposition of starch.

[0036] S2: After the saccharification is completed, after the iodine test is passed, the temperature is rai...

Embodiment 1

[0045] like figure 1 Shown, the preparation method of the hop fragrance IPA beer of high alcohol content, high bitter quality, specifically comprises the following steps:

[0046] Ayer malt (accounting for 82% of the total amount of raw materials), caramel malt (accounting for 18% of the total amount of raw materials) and water are used as the main raw materials. Mix in the same ratio, keep warm at 48°C for 40 minutes, then raise the temperature to 63°C and keep warm for 70 minutes;

[0047] After the saccharification is completed, after passing the iodine test, the temperature is raised to 78°C to filter the wort and wash the tank to obtain the wort;

[0048] During the wort boiling process, add hop Cascade or Simco 3 times, add hop Cascade or Simco respectively at the initial boiling, 50 minutes of boiling, and 60 minutes of final boiling, and the addition amount is respectively 3kg / kL, 4kg / kL and 7kg / kL, wort whirlpool sedimentation after boiling, in the whirlpool sedimen...

Embodiment 2

[0052] like figure 1 Shown, the preparation method of the hop fragrance IPA beer of high alcohol content, high bitter quality, specifically comprises the following steps:

[0053] Ayer malt (accounting for 84% of the total amount of raw materials), caramel malt (accounting for 16% of the total amount of raw materials) and water are used as the main raw materials. Mix in the same ratio, keep warm at 50°C for 30 minutes, then raise the temperature to 65°C and keep warm for 65 minutes;

[0054] After the saccharification is completed, after passing the iodine test, the temperature is raised to 78°C to filter the wort and wash the tank to obtain the wort;

[0055] During the wort boiling process, add hop century or spring 3 times, add hop century or spring 1 time respectively at the initial boiling, 50 minutes of boiling, and 65 minutes of final boiling, and the addition amount is 4kg / kL, 5kg / kL and 6kg respectively / kL, after the boiling is completed, carry out whirlpool precip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com