Ethylene vaporization system and preparation method thereof

A control method, ethylene technology, applied in the direction of container filling method, container discharge method, pressure vessel, etc., can solve the problems of increasing operating costs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

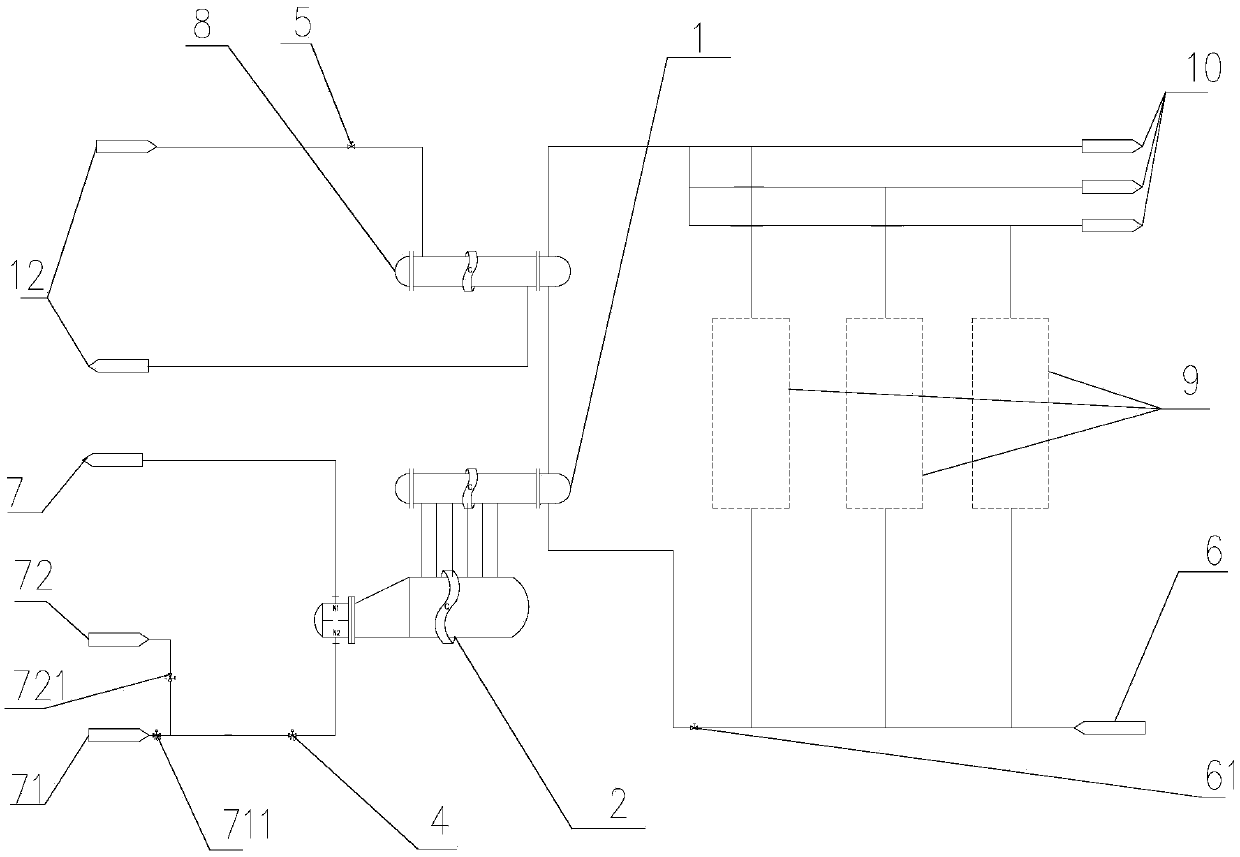

[0041] see figure 1 As shown, the present invention provides an ethylene vaporization system, which includes an ethylene vaporizer 1, a heat medium supply device, and a circulating water pipeline 7. The heat medium supply device communicates with the ethylene vaporizer 1 to form a heat medium circulation loop. The heat medium supply device includes There is a heat exchange part, and the circulating water pipe 7 exchanges heat with the heat exchange part, so as to heat the heat exchange medium inside the heat exchange part through the circulating water.

[0042] In the above scheme, by using circulating water as a heat source to vaporize liquid ethylene, compared with the existing technology, the high-quality energy such as steam is saved, which brings huge economic benefits to the enterprise.

[0043] Preferably, the heat medium supply equipment selects a heat exchange medium with a boiling point lower than that of circulating water and higher than that of ethylene;

[0044] ...

Embodiment 2

[0054] This embodiment provides the control method of the ethylene vaporization system in the above embodiments. The ethylene vaporization system includes an ethylene vaporizer 1, a heat medium supply device, and a circulating water pipeline 7. The heat medium supply device communicates with the ethylene vaporizer 1 to form a heat medium circulation loop. The heat medium supply equipment includes a heat exchange part, and the circulating water pipe 7 exchanges heat with the heat exchange part. The control method includes: controlling the water flow in the circulating water pipe 7 to heat the heat inside the heat medium supply equipment The heat exchange medium vaporizes the liquid ethylene entering the ethylene vaporizer 1 through the heat exchange medium.

[0055] Preferably, the circulating water is controlled to heat the heat exchange medium, so that the heat exchange medium vaporizes and enters the ethylene vaporizer 1 to exchange heat with ethylene, and the heat exchange m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com