Sandwich Dyeing Process for Colored Contact Lenses

A contact lens, printing and dyeing technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of lens focal power deterioration, oxide layer generation, unclear, etc., achieve clear focus, improve hydrophilicity, Safe and comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

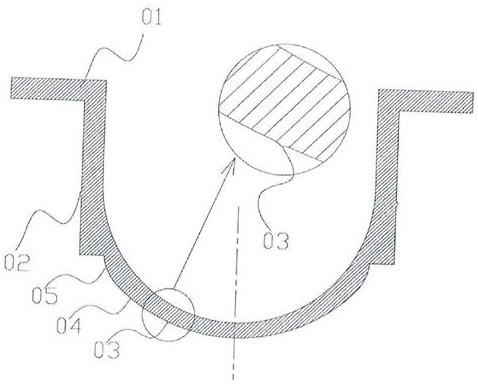

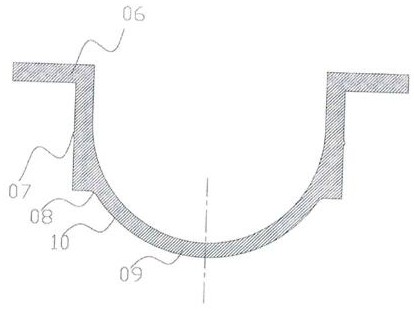

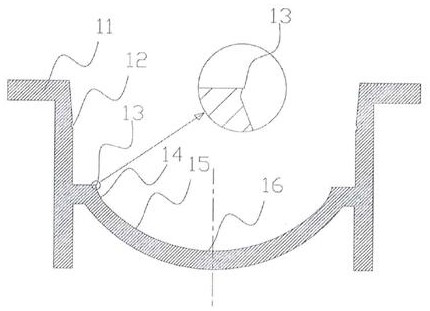

[0030] Please also refer to Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the upper mold I of the embodiment of the present invention; figure 2 It is the upper mold II schematic diagram of the embodiment of the present invention; image 3 It is the lower mold schematic diagram of the embodiment of the present invention. As shown in the figure, a color contact lens sandwich dyeing process includes:

[0031] Design the upper mold I01 without optical function, the upper mold II06 with optical function on the outer arc surface, and the lower mold 11 with optical function on the inner arc surface.

[0032] The outer surface of the upper mold Ⅰ01 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com