Automatic production line based on food processing

An automatic production line and food processing technology, which is applied in food processing, food science, application, etc., can solve the problems of inconvenient removal and increased difficulty in taking raw materials, and achieve the effects of convenient cleaning, reduced disassembly difficulty, and guaranteed practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

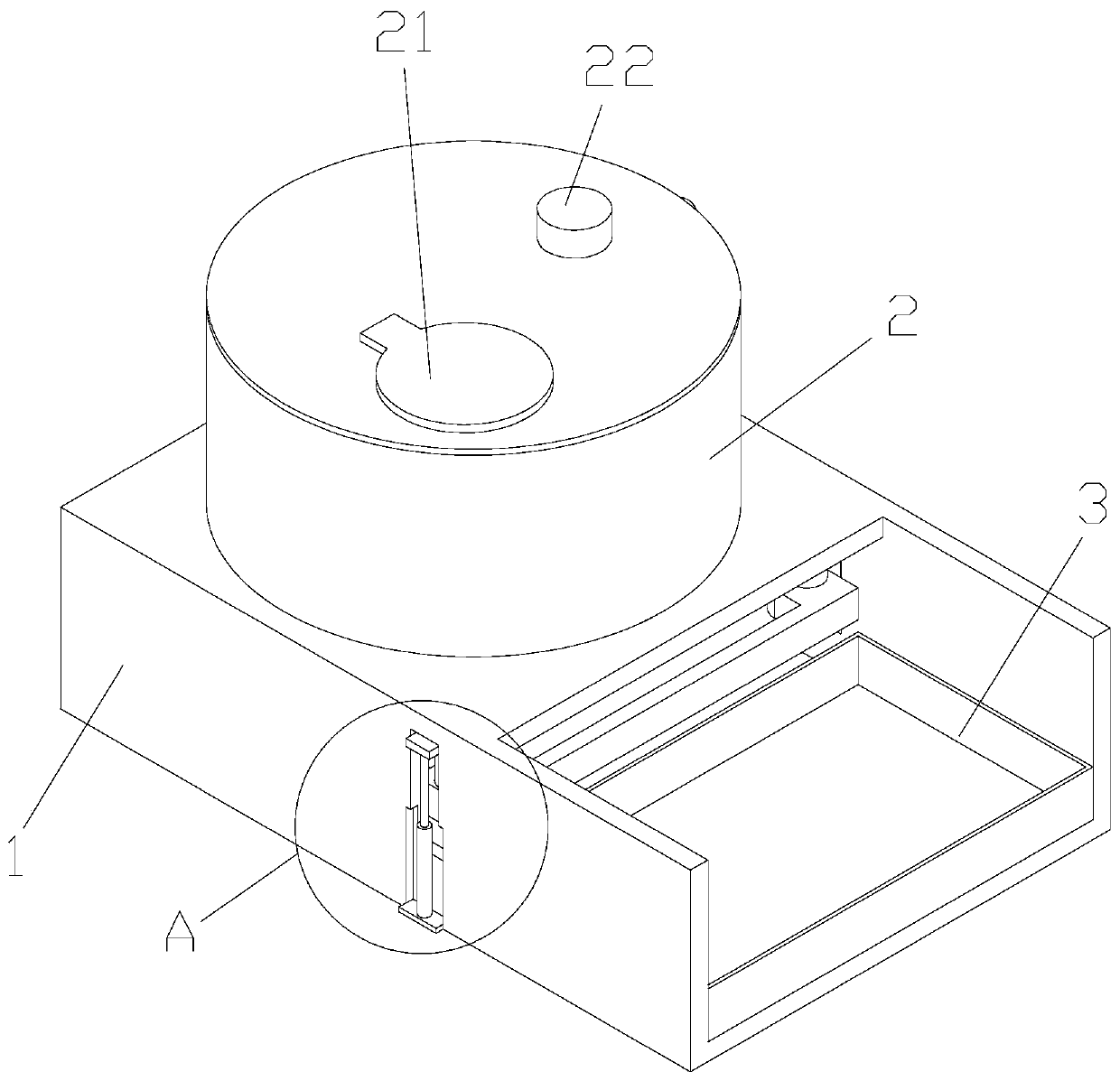

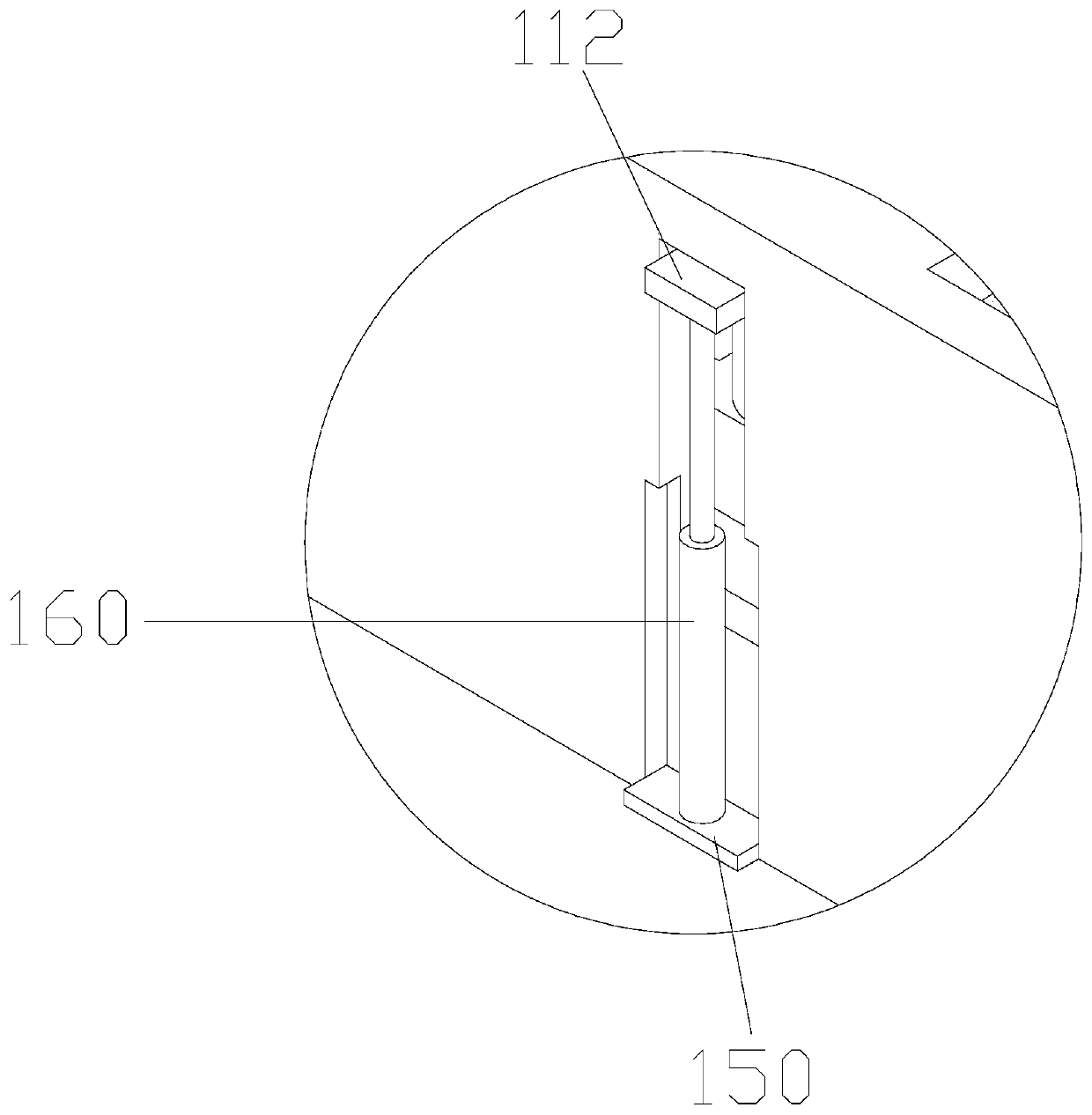

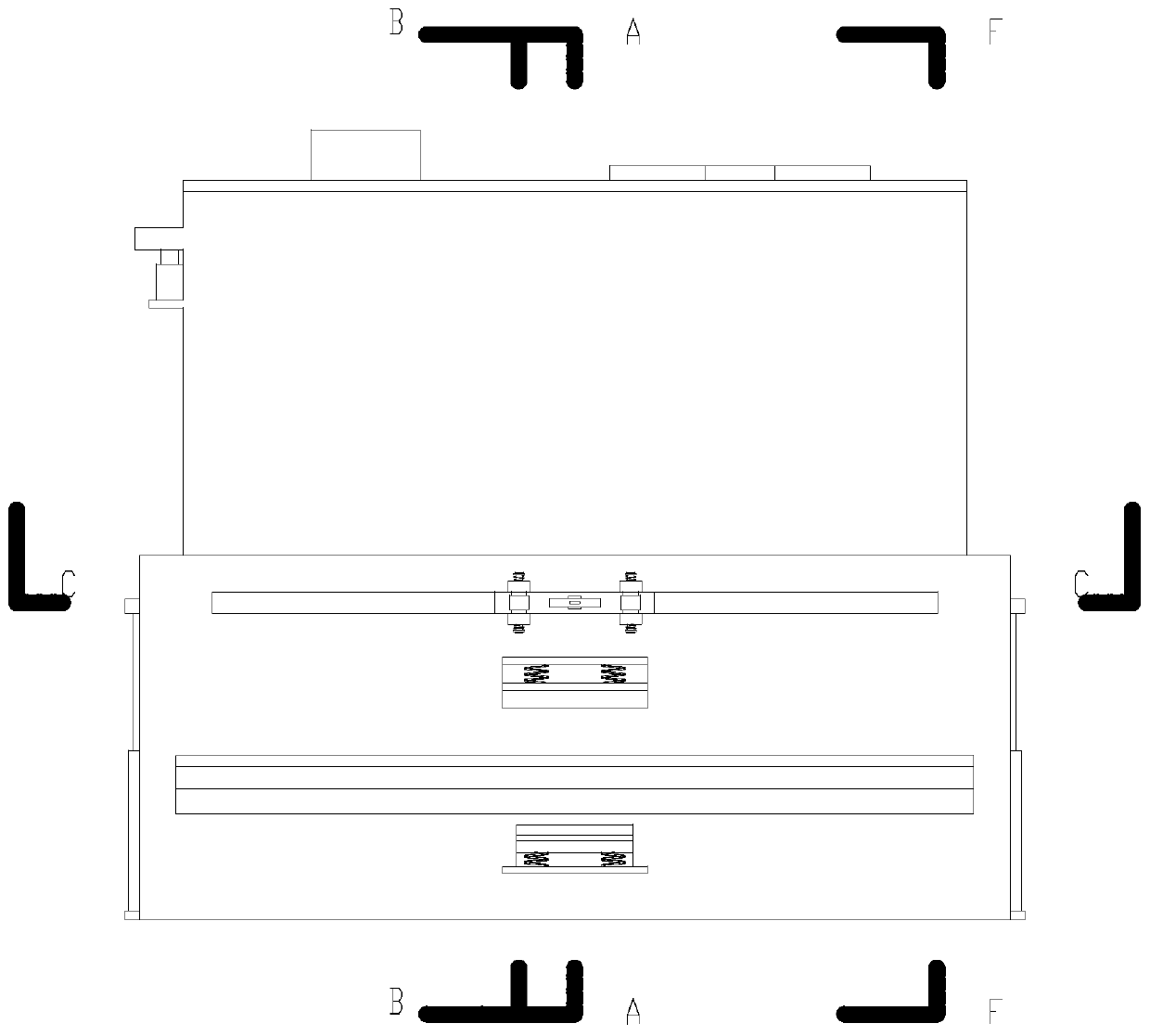

[0033] like Figure 1-17 As shown, an automatic production line based on food processing includes drying equipment and stir-frying equipment. The conveyor belt is connected, the drying equipment includes a lower box body 1 and an upper box body 2, the top of the upper box body 2 is provided with a top cover, the top cover is provided with a feed port, and the top cover is provided with a The cover plate 21 matched with the feed inlet is rotatably connected to the top cover, the top cover is provided with a hot air blower 22, the upper box 2 is provided with a stirring assembly, and the lower box 1 communicates with the upper box 2, the lower box 1 is provided with a support plate 11, one end of the support plate 11 is rotatably connected to the inner wall of the lower box 1, and the support plate 11 is provided with Installing groove, described installing groove is provided with sieve plate 12, described lower box body 1 is provided with the cylinder 160 that is used to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com