An electric hoist automatic processing production line

An electric hoist and production line technology, which is applied in metal material coating process, conveyor objects, transportation and packaging, etc., can solve the problems of difficulty in reclaiming the chain link, limited length of the chain link, and difficulty in taking out the chain link. The effect of reducing the difficulty of material, increasing the contact effect, and improving the convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

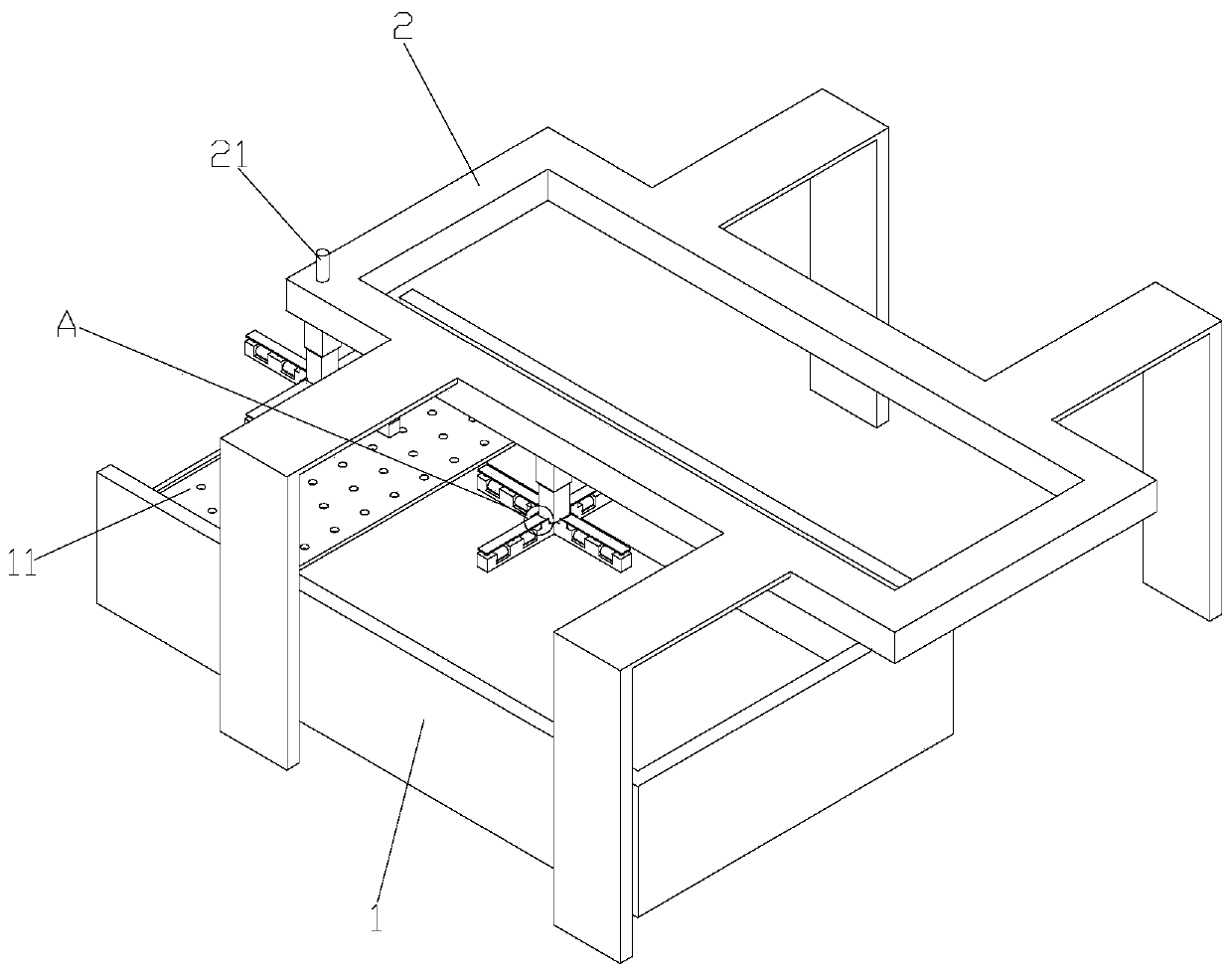

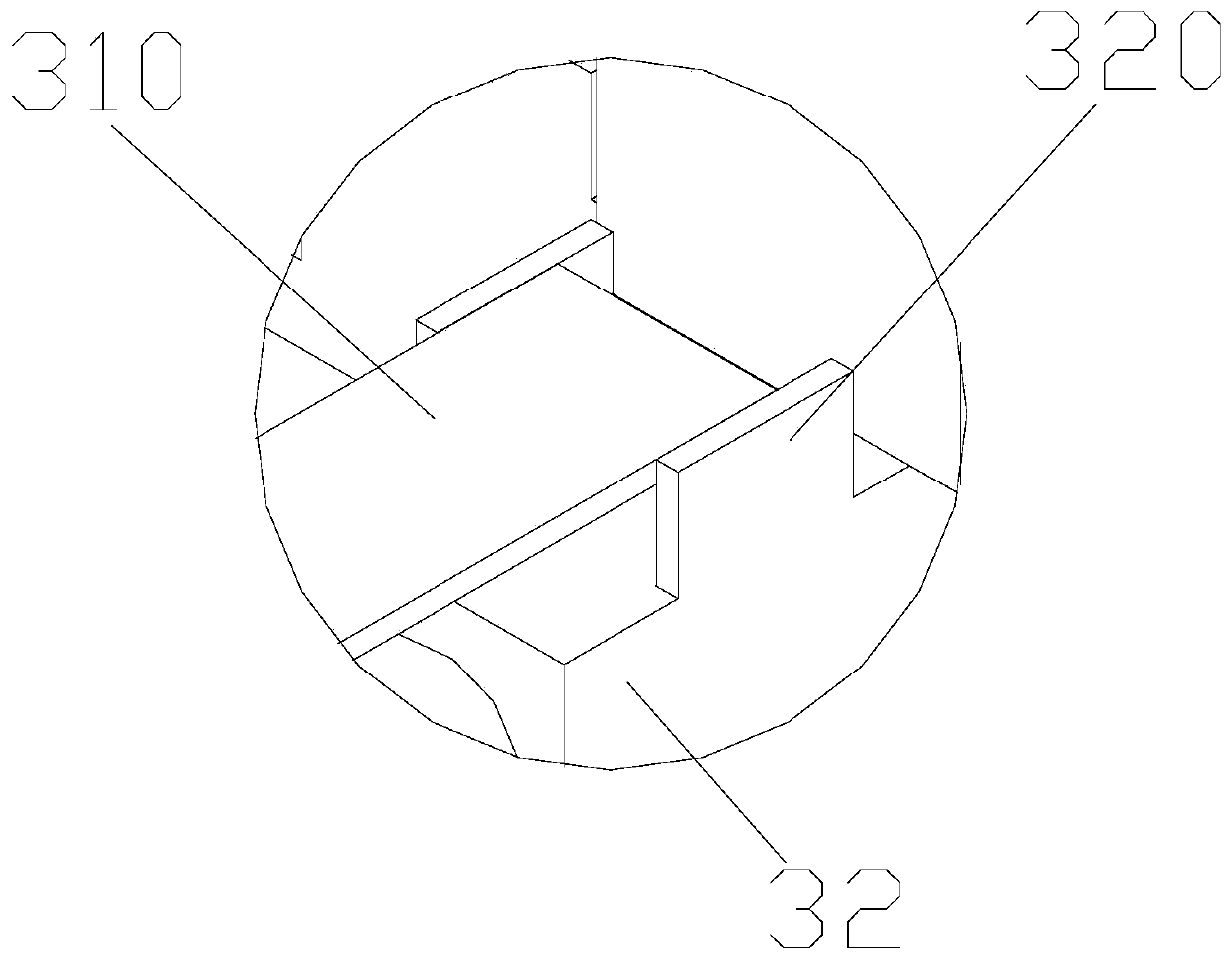

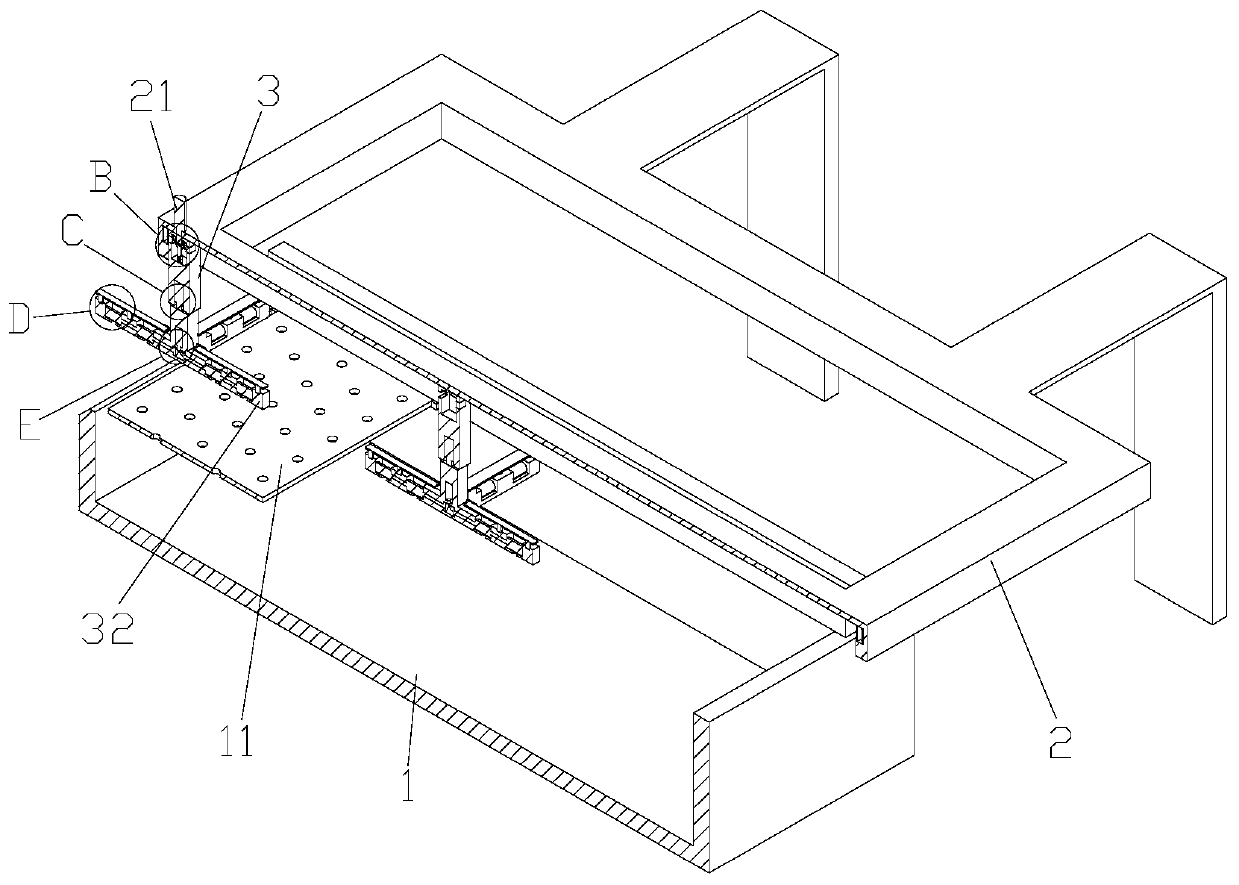

[0030] Such as Figure 1-14 As shown, an electric hoist automatic processing production line includes a liquid storage tank 1, a guide rail 2 arranged above the liquid storage tank 1 and a conveying assembly arranged on the guide rail 2, and a guide groove is provided on the guide rail 2 , the inner wall of the guide groove is provided with a first movable groove, and a transmission roller is arranged in the first movable groove, and a transmission belt is set on the transmission roller, and the guide rail is a quadrilateral structure, and the feeding assembly can move circularly on the guide rail , the four inner walls of the guide groove are respectively provided with transmission belts, so that the guide block can move normally on the guide groove on each side; The first connecting rod 3 at the bottom, the second connecting rod 31 located at the bottom of the first connecting rod 3 and the carrier 32 located at the bottom of the second connecting rod 31, the carrier is a cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com