Ore crushing device with dust falling mechanism

A technology of ore crushing and dust reduction, which is applied in the direction of grain processing, etc., can solve the problems of surrounding ecological environment damage, threat to workers' health, pollution of the working environment, etc., achieve good dust reduction effect, avoid random floating, and improve the effect of dust reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

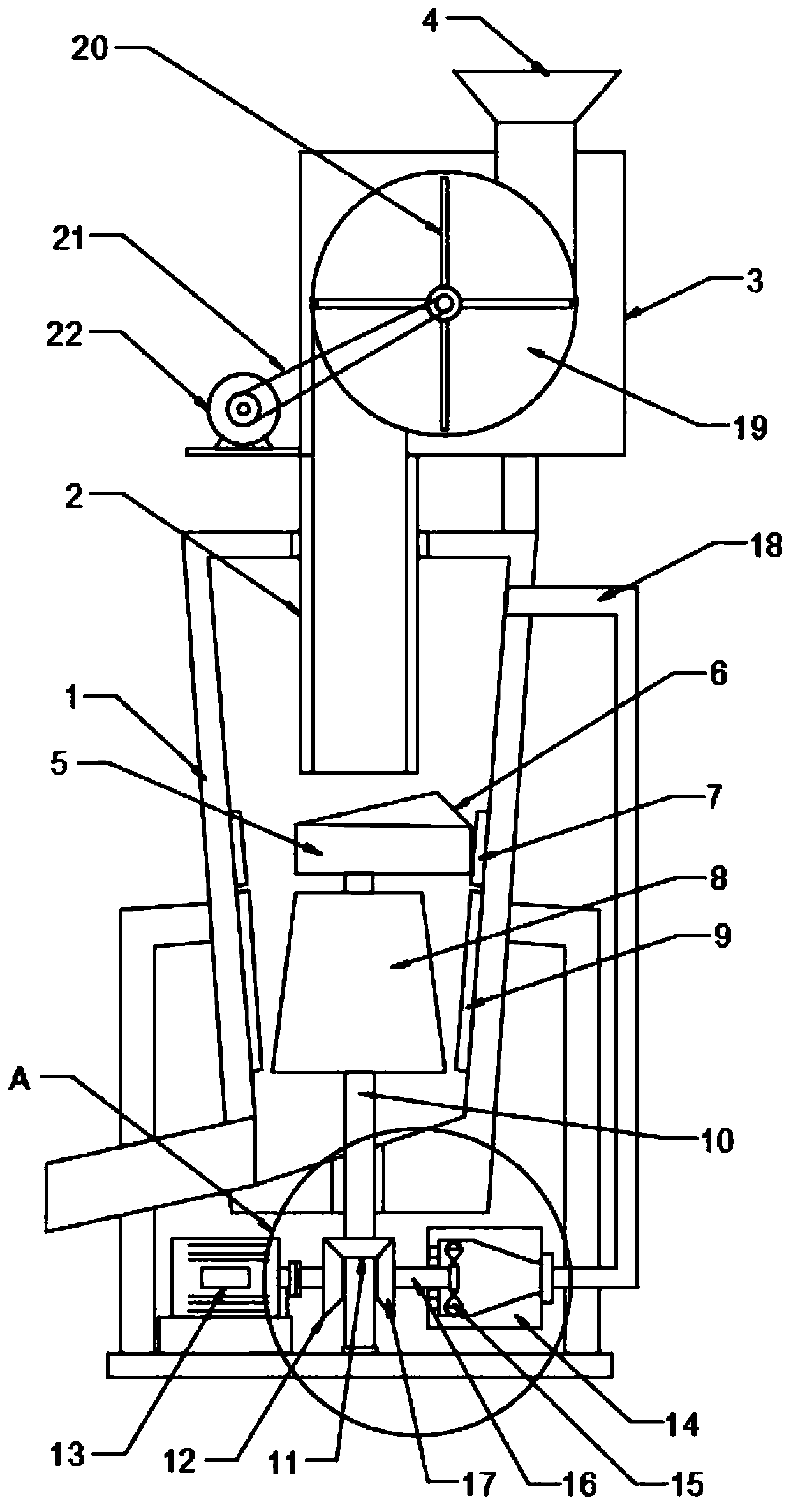

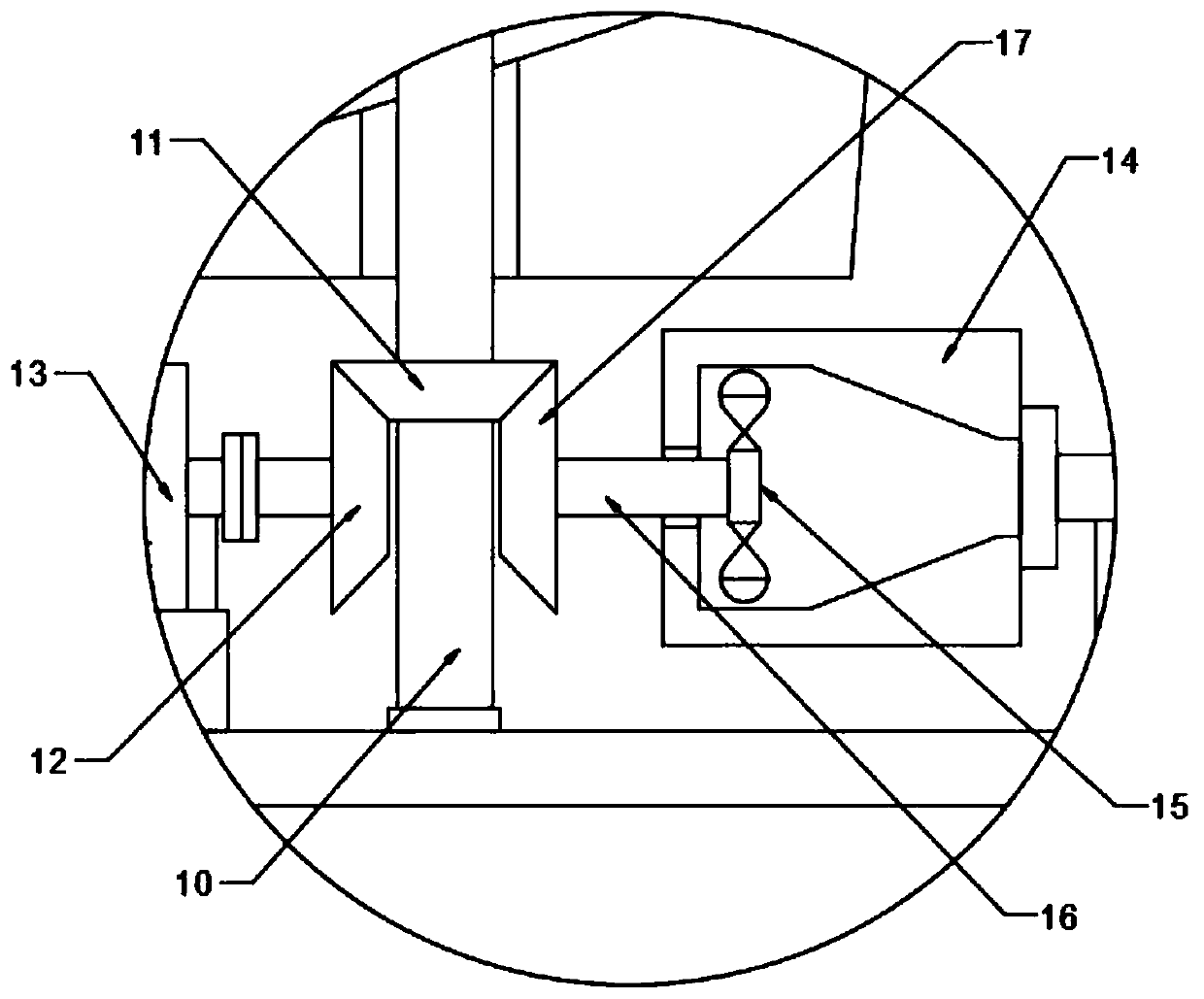

[0021] see Figure 1-3 , in the embodiment of the present invention, a kind of ore pulverizing device that contains dust-reducing mechanism, comprises pulverizing cylinder 1 and grinding roller 8; Said pulverizing cylinder 1 is the cone-shaped hollow cylinder of upper width and lower narrow, and pulverizing cylinder 1 is provided with grinding roller 8. There is a grinding shell 9 on the outside of the grinding roller 8, and the grinding shell 9 is fixedly connected with the inner wall of the grinding cylinder 1; the lower end of the grinding roller 8 is fixedly connected with a rotating shaft 10, and the rotating shaft 10 extends to the bottom of the grinding cylinder 1 and rotates through the bearing seat Connected with a base; the rotating shaft 10 is sleeved with a central bevel gear 11, the central bevel gear 11 is engaged with a left bevel gear 12, and the left bevel gear 12 is fixedly connected with the output shaft of a driving motor 13, and the driving motor 13 drives ...

Embodiment 2

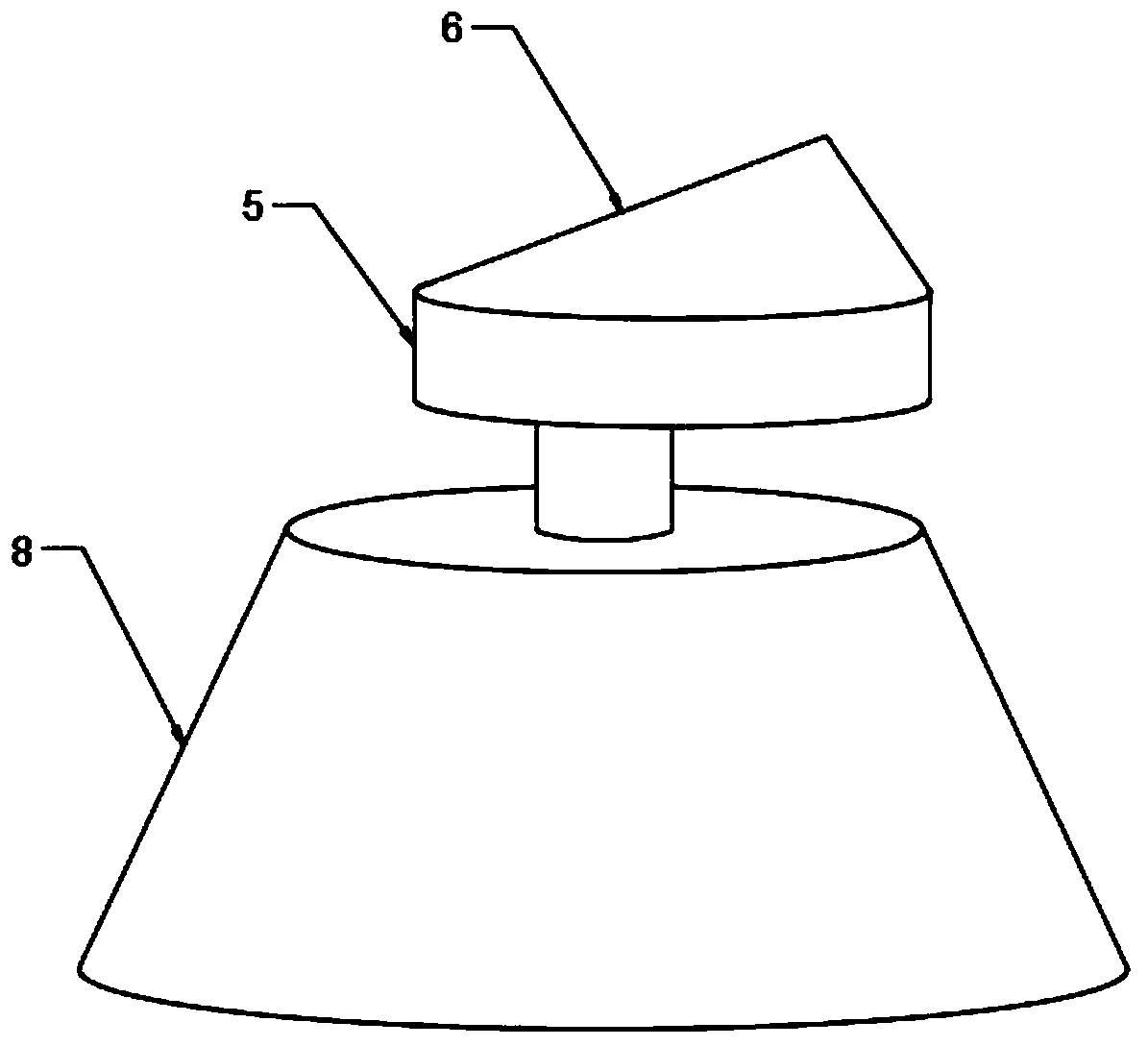

[0025] The difference between this embodiment and Embodiment 1 is that in order to further ensure the speed and effect of ore crushing, an eccentric extrusion disk 6 is arranged above the grinding roller 8, and a connecting shaft is fixedly connected to the peripheral edge of the eccentric extrusion disk 6, and the lower end of the connection shaft It is fixedly connected with the center of the upper end surface of the grinding roller 8, that is, when the grinding roller 8 rotates and grinds, the eccentric extrusion disc 6 is driven to make a circular motion through the connecting shaft, and an annular impact plate 7 is arranged on the outside of the eccentric extrusion disc 6, 7 is fixedly connected with the inner wall of the crushing cylinder 1, and the eccentric extrusion disc 6 cooperates with the impact plate 7 to preliminarily crush and crush the ore to reduce the size of the ore particles, so as to prevent the ore particles from being too large and unable to enter the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com