Solid-liquid oil-water separation device for kitchen waste

An oil-water separation device, a technology for kitchen waste, applied in the directions of liquid separation, immiscible liquid separation, separation methods, etc., can solve problems such as difficult cleaning, odor emission of collection devices, breeding of bacteria and mosquitoes, etc. The effect of facilitating transparency and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

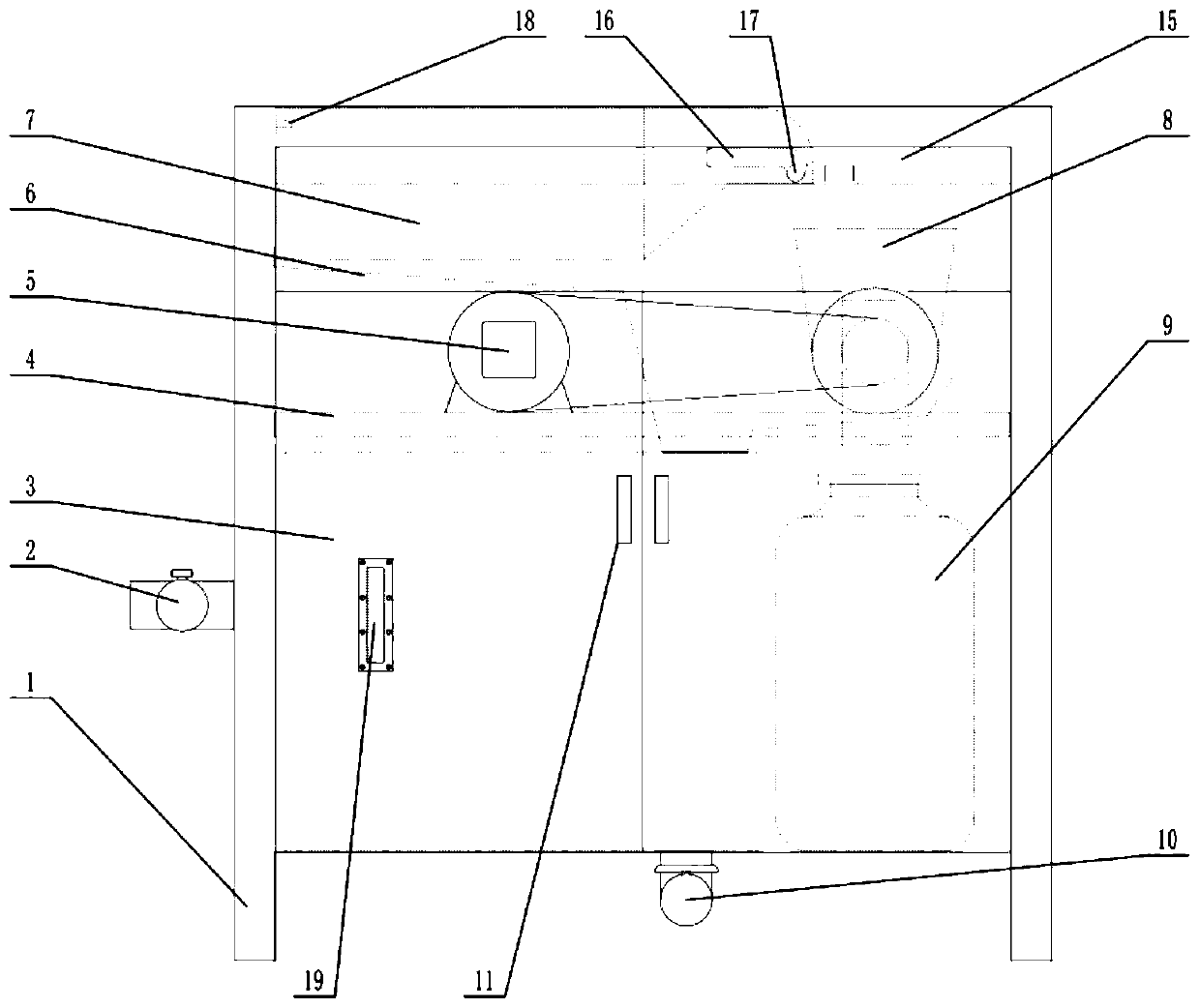

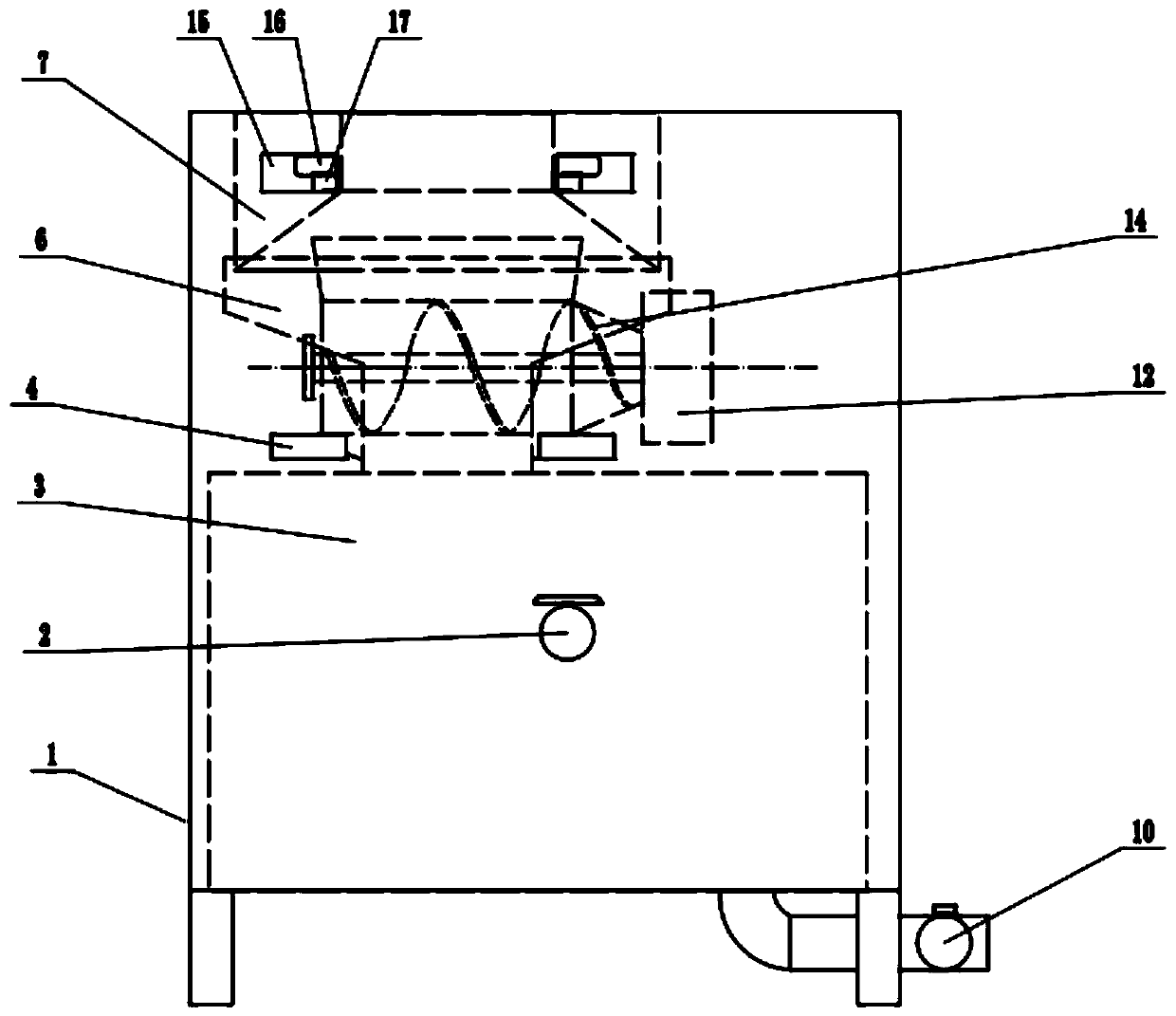

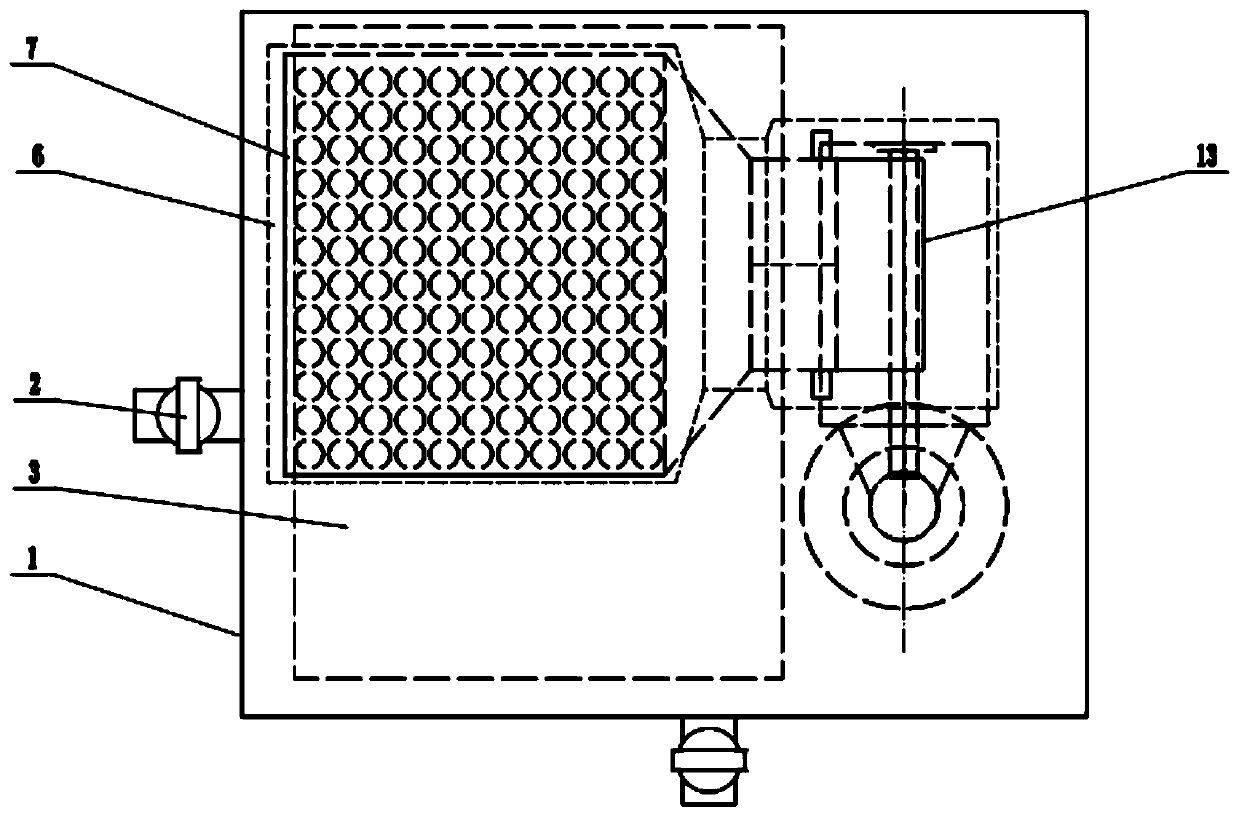

[0043] Specific implementation mode one: see Figure 1-13 This embodiment will be described. A food waste solid-liquid oil-water separation device described in this embodiment includes a box body 1, an oil-water separator 3, a fixed bracket 4, a driving device 5, a residual liquid collector 6, a solid-liquid separator 7, and a residue collection port 8 , a residue collection container 9, a residue discharge port 12 and a screw extrusion device 14; a solid-liquid separator 7 is installed on the top of the casing 1, and a residual liquid collector 6 is installed below the solid-liquid separator 7, The below of described raffinate collector 6 is equipped with fixed support 4, and described fixed support 4 is fixed with driving device 5 and screw extruding device 14, and described driving device 5 drives screw extruding device 14 to rotate, and described driving device 5 includes a drive motor and a reducer, driven by a belt, an oil-water separator 3 is installed under the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com