Forming method of large-size curved surface thin-wall metal skin

A curved, thin-walled technology, applied in the field of forming large-sized curved thin-walled skins, can solve the problems of high component manufacturing cost, long production cycle, and high equipment requirements, and achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

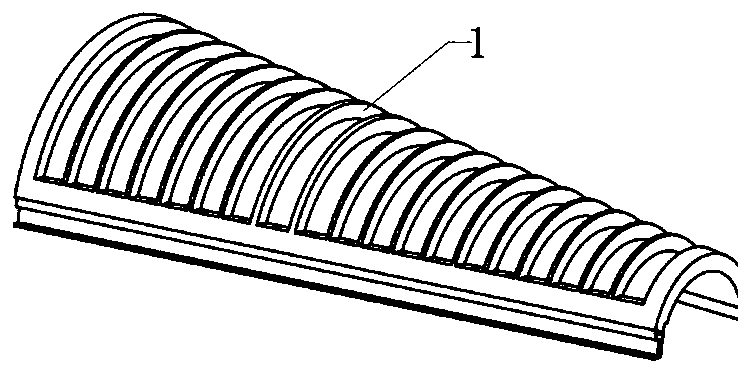

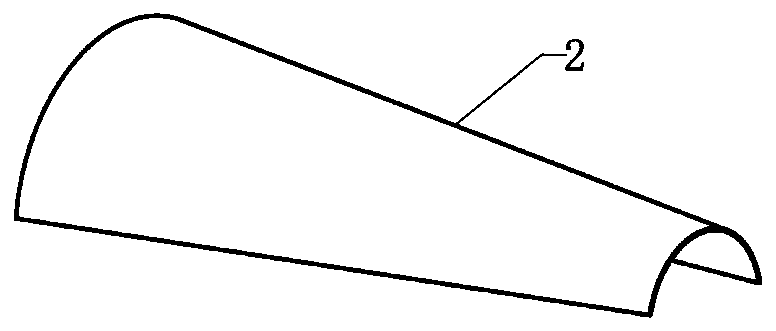

[0033] see image 3 Explain, a kind of forming method of large-scale curved surface thin-walled metal skin, concrete steps are as follows:

[0034] Step 1. According to the assembly relationship between the curved wall panel and the thin-walled skin, extract the position and size characteristics of the stiffener on the curved surface panel;

[0035] Step 2. Assuming that the assembled thickness between the curved wall panel and the thin-walled skin is m, determine the size of the forming punch based on the shape and size of the curved wall panel, and use the forming surface size of the punch as a benchmark to measure the forming surface along the method. The outer side of the line is offset by m thickness to obtain the inner surface characteristics of the die;

[0036] Step 3, according to the thickness of the curved wall plate, determine that the size of the discrete support mold is consistent with the size of the curved surface wall plate, and determine the forming surface ...

Embodiment 2

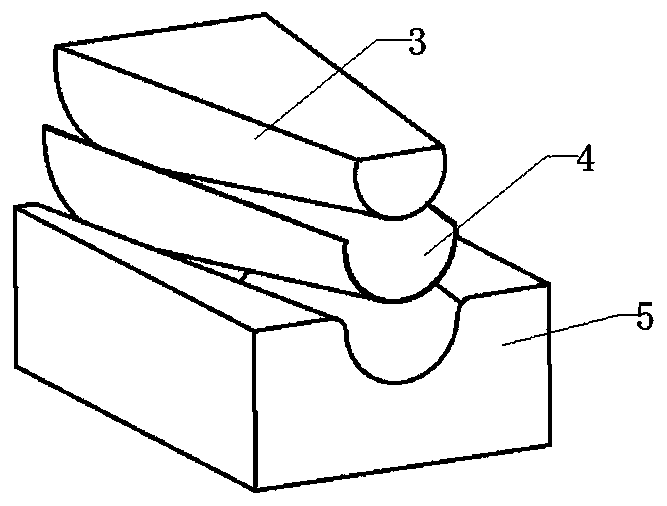

[0043] see Figure 4 Explain, a kind of forming method of large-scale curved surface thin-walled metal skin, concrete steps are as follows:

[0044] In step 6, n discrete support molds are distributed on the punch, and the dispersed position of the support mold can be determined according to the position of the reinforcing rib on the curved wall plate, and the replacement rib of the support mold is distributed on the punch, and discrete The scattered positions of the supporting dies of the supporting dies can also be adjusted according to the forming conditions of the thin-walled slab after forming, which is the same as that in Embodiment 1.

[0045]When the plate is formed by the integral mold, due to the uneven load distribution and different contact states on the slab, it is easy to wrinkle and warp during forming, and there is a certain distance between the discrete support molds. By adjusting the discrete Supporting the position of the mold on the punch can easily elimin...

Embodiment 3

[0047] see Figure 5 Explain, a kind of forming method of large-scale curved surface thin-walled metal skin, concrete steps are as follows:

[0048] In step six, the discrete support mold and the punch can be effectively connected by bolts, and the discrete support mold is composed of multiple small molds with surface shape and size requirements. Each discrete supporting mold adopted in other steps is composed of a plurality of small mold blocks, and gaps exist between adjacent small mold blocks. Other steps are the same as in the first embodiment.

[0049] In the traditional stamping forming process, most of the molds adopt the integral form, which is prone to excessive local contact stress and unnecessary deformation. The discrete support mold composed of multiple small mold blocks is only in partial contact with the thin-walled slab, and the areas on the thin-walled skin that do not need to be assembled with the reinforcing ribs are in a relatively free state, which can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com