Polyurethane resin perfusion structure and molding method of wind power generation blade

A wind power generation blade and polyurethane resin technology, which is applied in the field of polyurethane resin infusion structure and molding of wind power generation blades, can solve problems such as rich glue and poor infiltration, and achieve the effects of avoiding poor infiltration, reducing risks, and improving poor infusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

[0030] Unless otherwise defined, all technical terms used hereinafter have the same meanings as commonly understood by those skilled in the art. The terminology used herein is only for the purpose of describing specific embodiments, and is not intended to limit the protection scope of the present invention.

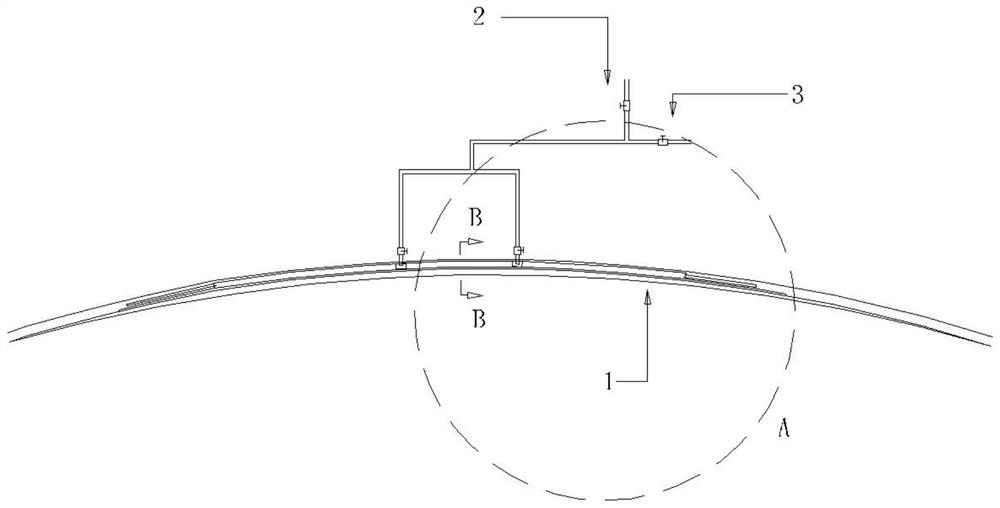

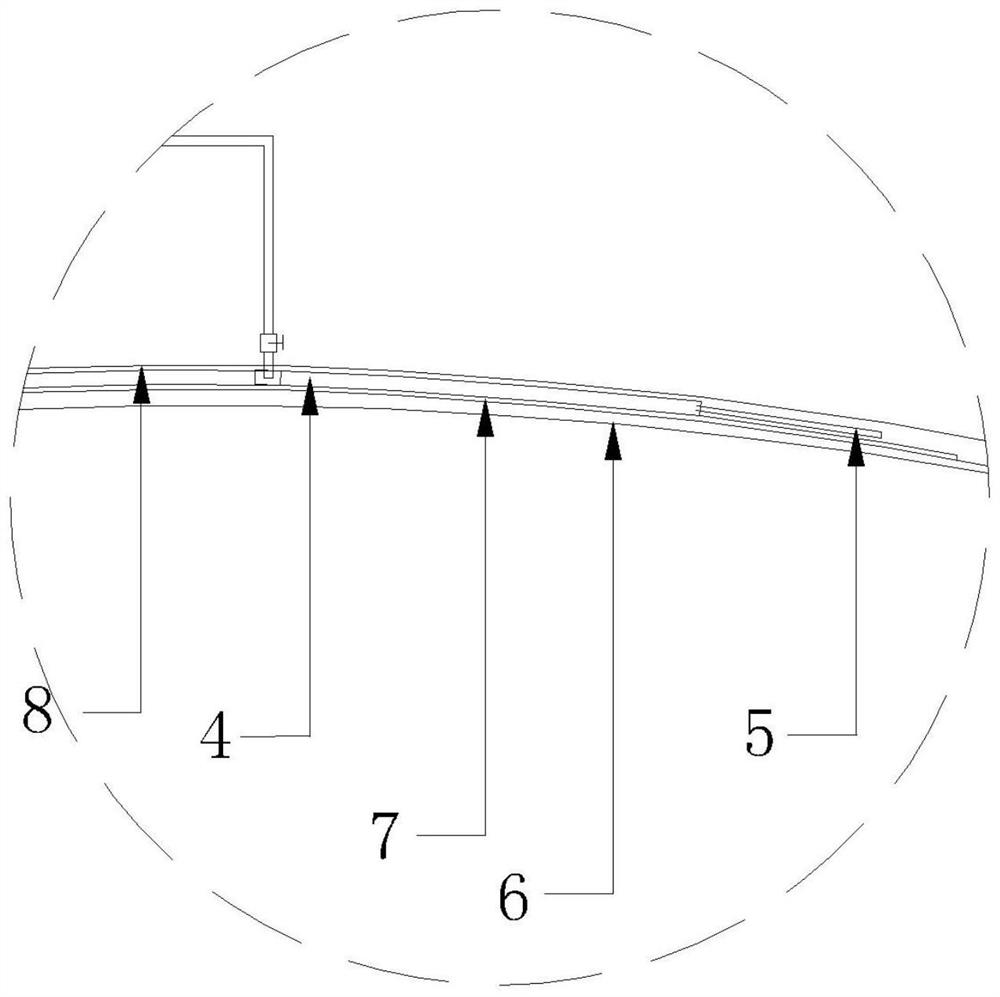

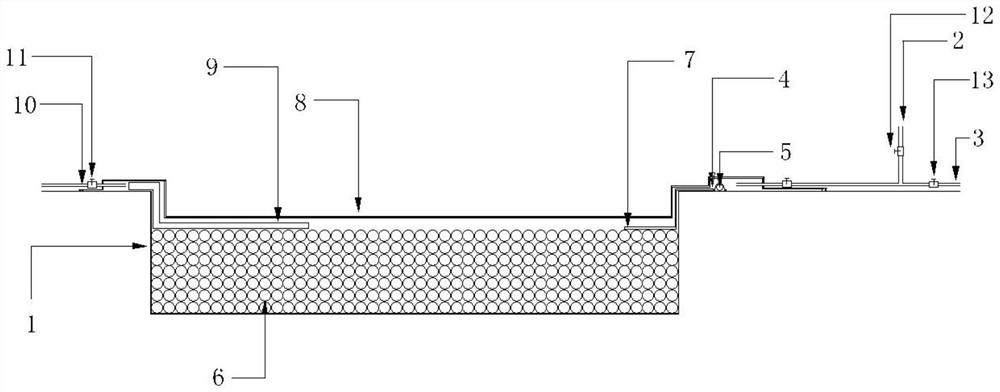

[0031] like Figure 1~3 , in one embodiment of the present invention, lay diversion net as bottom diversion medium (not shown in the figure) at the bottom of mold 1, diversion net string to the left end distance suction side (vacuum pipeline 10 side, such as image 3 ) The façade of the mold is 80±10mm, and the chord extends to the right side to the flange, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com