Fuel oil leakage detection system of civil aviation passenger plane and detection method

A leak detection and fuel system technology, applied in the testing of machine/structural components, measuring devices, fluid tightness testing, etc. It can solve problems such as time-consuming, leakage, and need for personnel to enter the fuel tank, avoiding professional and complex operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

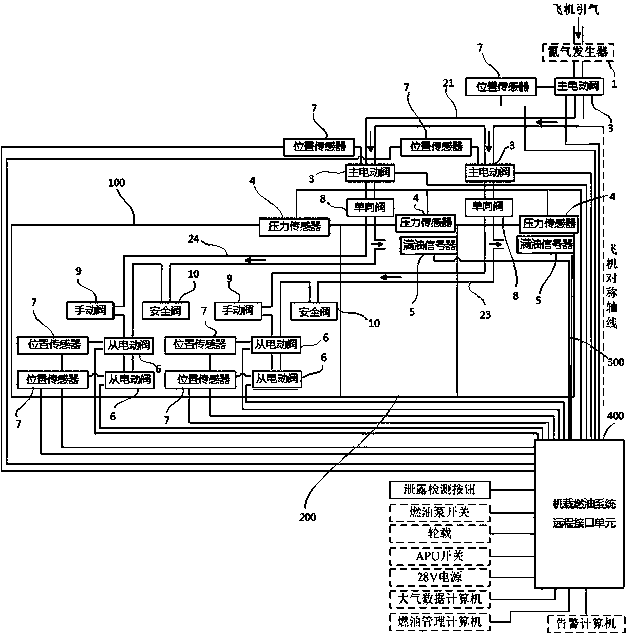

[0031] The on-board fuel system remote interface unit 400 in the present invention adopts the on-board fuel system remote interface unit 400 disclosed in the patent CN 105329450 A. Aircraft fuel tank comprises wing outer fuel tank 200, wing inner fuel tank 300 and ventilation fuel tank 100; Nitrogen generator 1 is the air separation device that is communicated with air, the nitrogen in the air is separated, and fills into each fuel tank of aircraft through vent pipe.

[0032] Such as figure 1 As shown, the civil aviation airliner fuel leakage detection system includes nitrogen generator 1, ventilation pipe, main electric valve 3, slave electric valve 6, position sensor 7, full fuel signal device 5, check valve 8, pressure sensor 4, safety valve 10. Manual valve 9.

[0033]Among them, the master electric v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com