A device and method for testing the free-flowability of coking coal in a thermoplastic state

A technology of coking coal and fluidity, which is applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve problems such as the inability to directly characterize the Gibbs fluidity, the weakening of coke strength, and the large fluidity value, so as to enrich the means and methods of coal quality detection Simple, fast, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

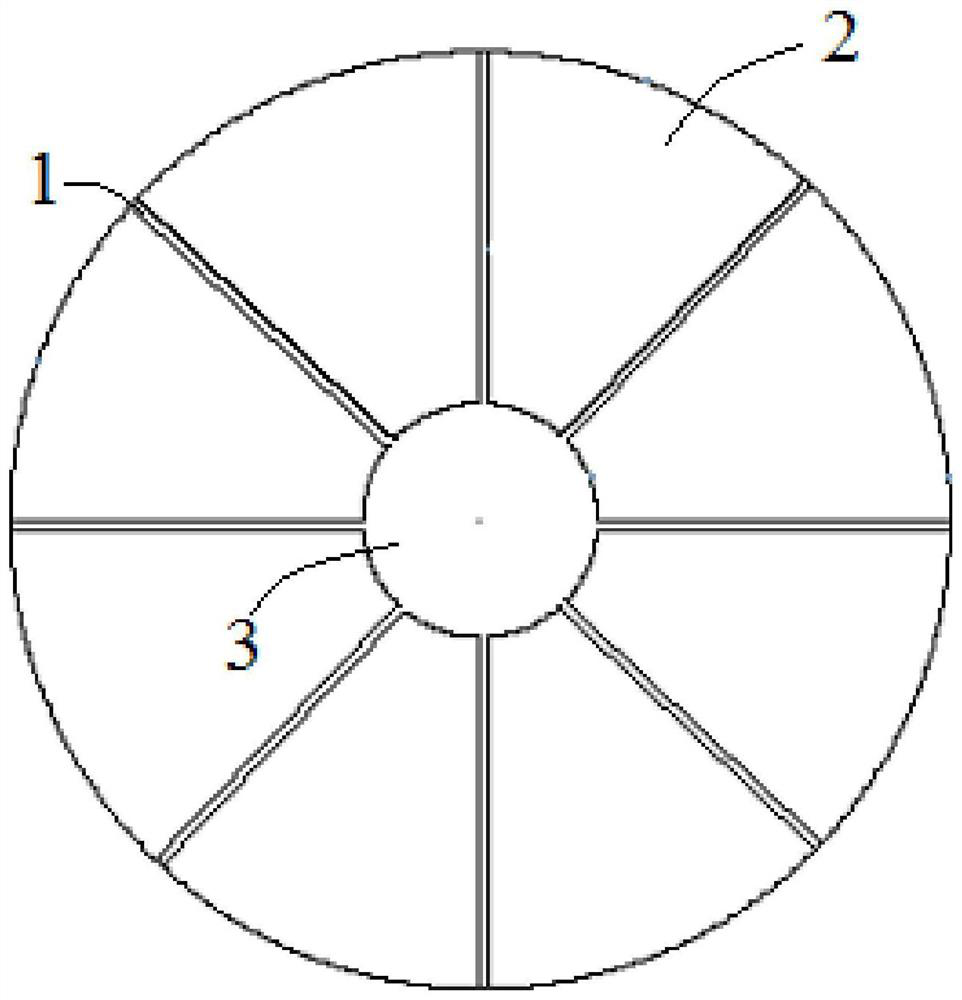

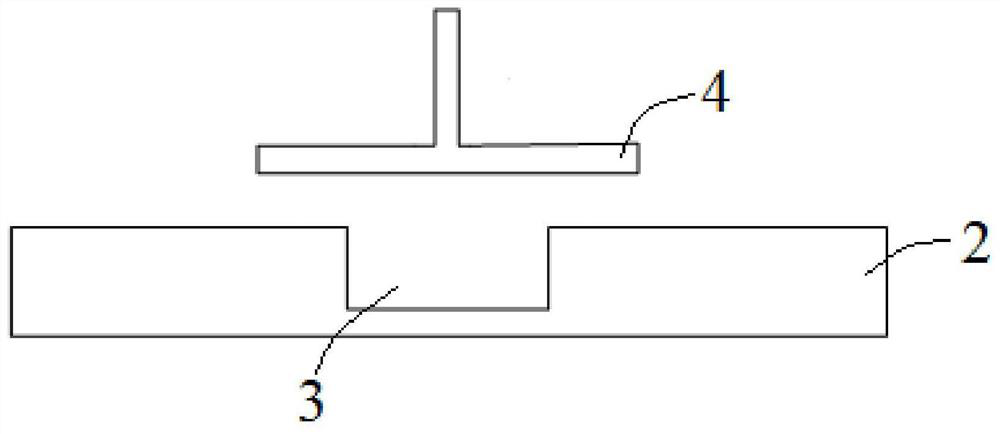

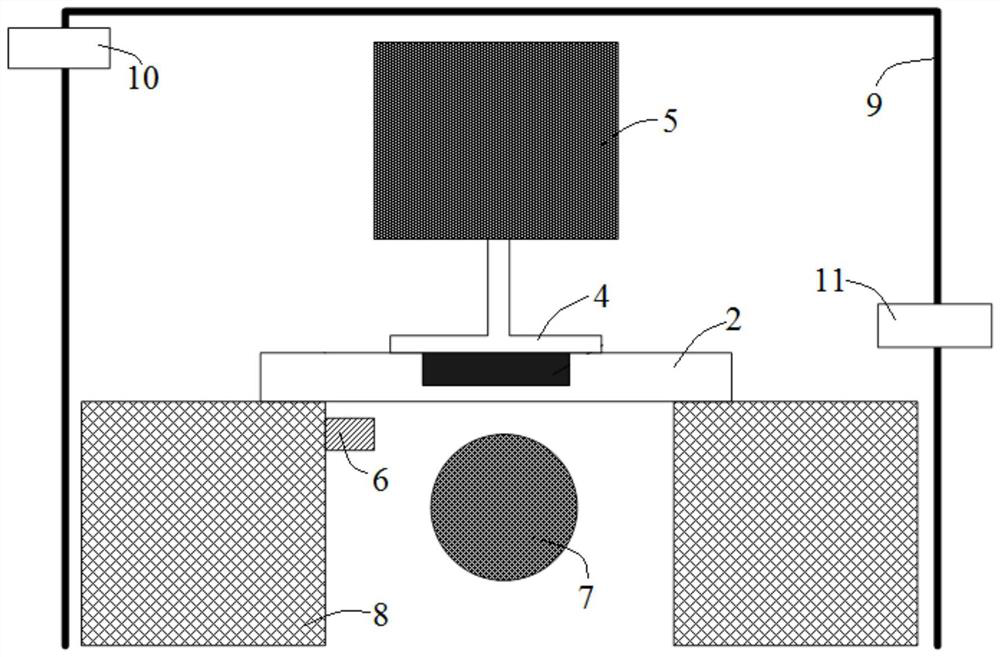

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment is specifically implemented as follows:

[0042] 1. Fragmentation and mirror group enrichment. The coal was first crushed to a 2 Solution centrifugation. For coking coal, it enriches the ZnCl of the mirror group 2 The solution density can be selected from 1.30 to 1.38g / cm 3 , the present embodiment selects a density of 1.30g / cm 3 ZnCl 2 solution. The ZnCl will be configured 2 The solution is poured into a centrifuge tube filled with crushed coal samples, put into a centrifuge, the centrifuge speed is controlled at 1500r / min, centrifuged for 10min and then left to stand, the floating matter is used as a mirror group enrichment product, and the floating matter is filtered, rinsed and dried. The selection of a mirror group to prepare coal briquettes, to exclude the influence of inert matter on the present embodiment, so that the test method of the present embodiment only characterizes a quality characteristic of the colloid to ensure the accuracy of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com