Efficient low-energy-consumption anti-blocking water cutting jet

A technology of water jet cutting machine and cutting machine tool, which is applied in filtration separation, metal processing, filtration circuit and other directions to achieve the effect of increasing effective working time, compact structure and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

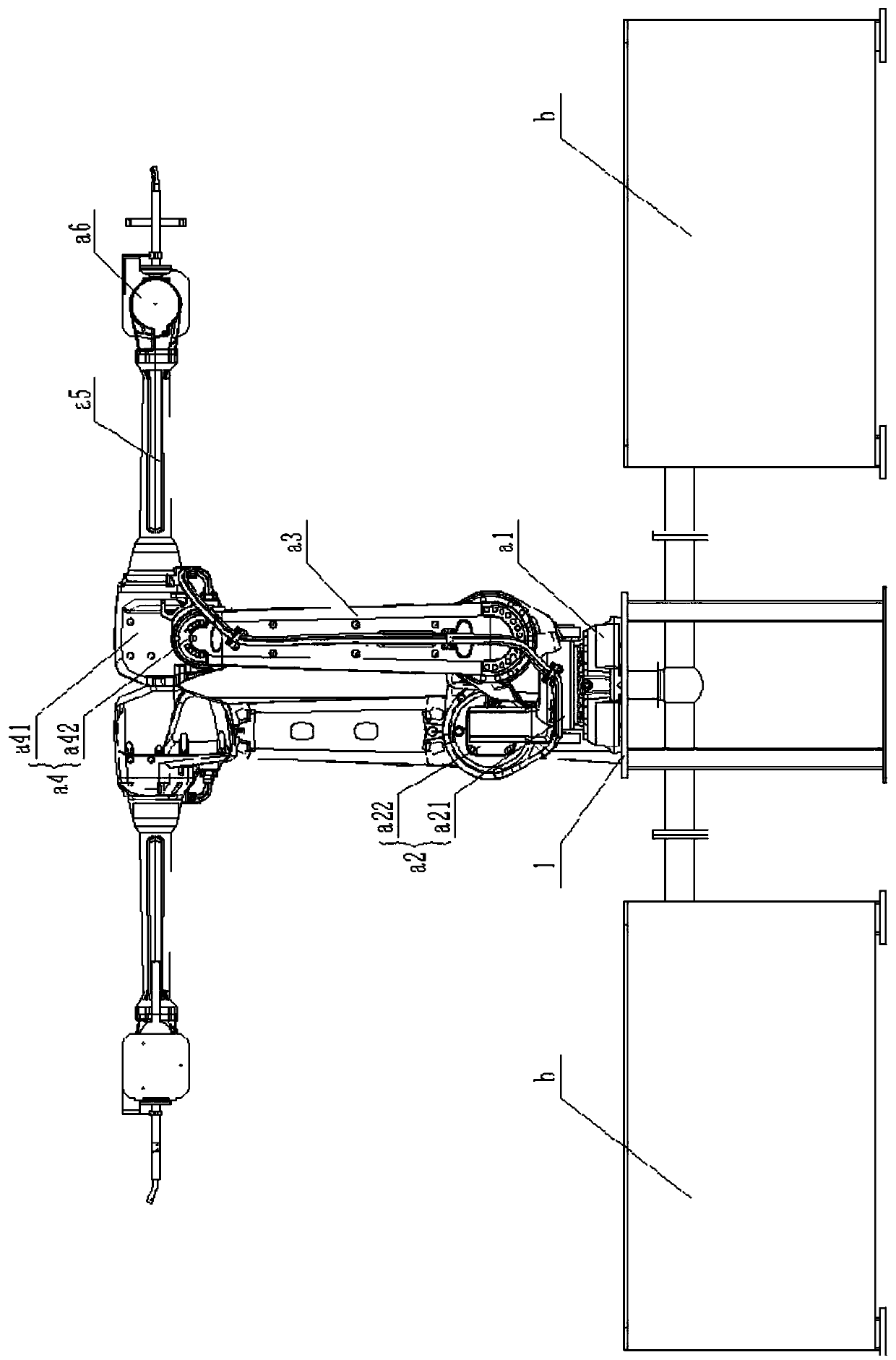

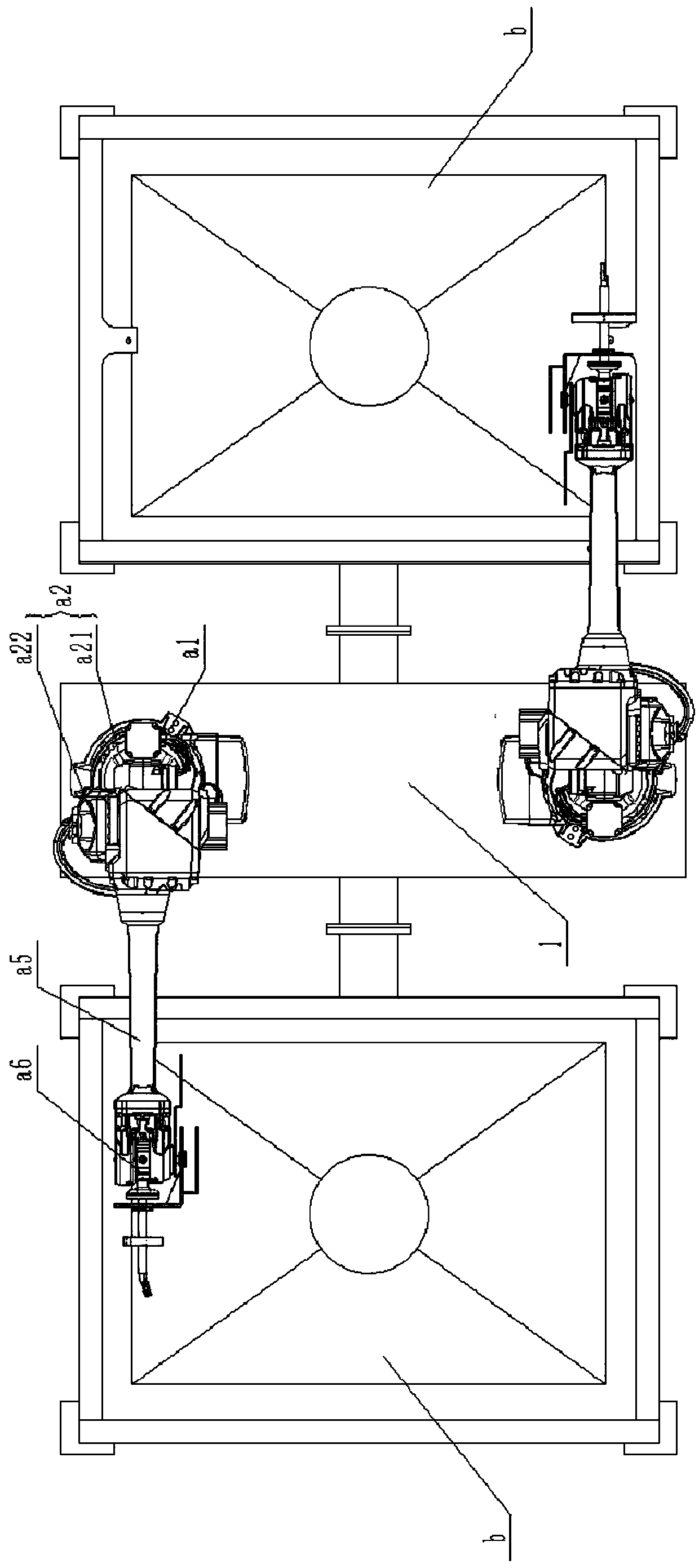

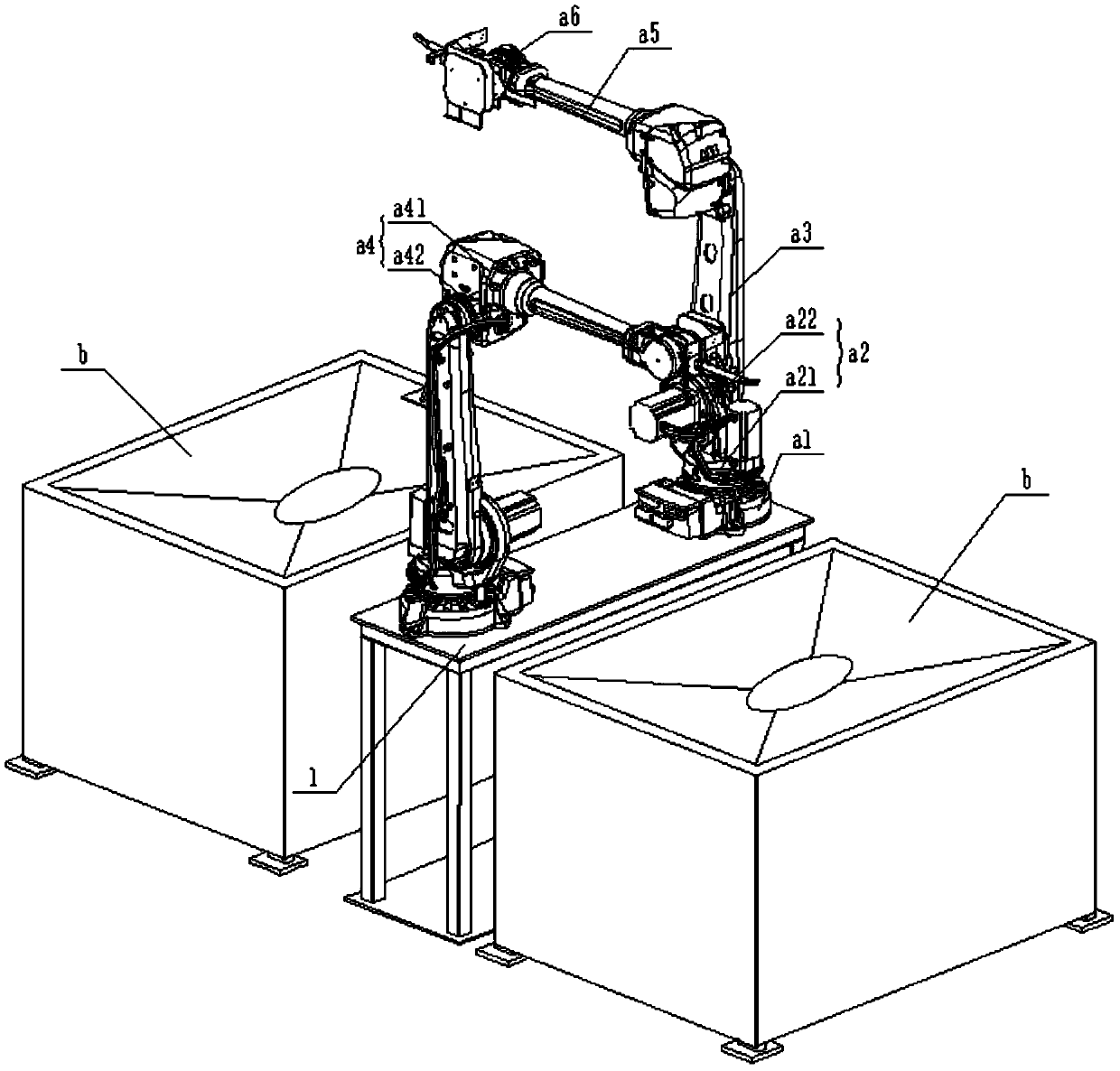

[0036] Such as Figure 1-7As shown, a high-efficiency, low-energy consumption and anti-clogging water cutting machine includes a water cutting robot a facing to each other. Two of the water cutting robots a are installed on the same base 1, and the two sides of the base 1 are facing to each other. There is a water cutting machine b, the water cutting machine b includes a platform body b1, the top of the platform body b1 is provided with a water collecting bucket b2, the bottom of the platform body b1 is connected with supporting legs, and the horizontal A separation seat b3 is provided, and the separation seat b3 isolates the platform body b1 into an upper muddy liquid area ba and a lower clean liquid area bb, the upper muddy liquid area ba is provided with a debris separation component b4, and the lower clean liquid area A centrifugal separation cylinder b51 is provided in the liquid area bb, and a liquid inlet pipe b52 is vertically arranged in the centrifugal separation cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com