Novel pulping tailing residue treatment equipment and treatment method thereof

A technology of processing equipment and processing methods, which is applied in the fields of fiber raw material processing, textiles and papermaking, and can solve the problems of large space occupation and poor maintenance of the site environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

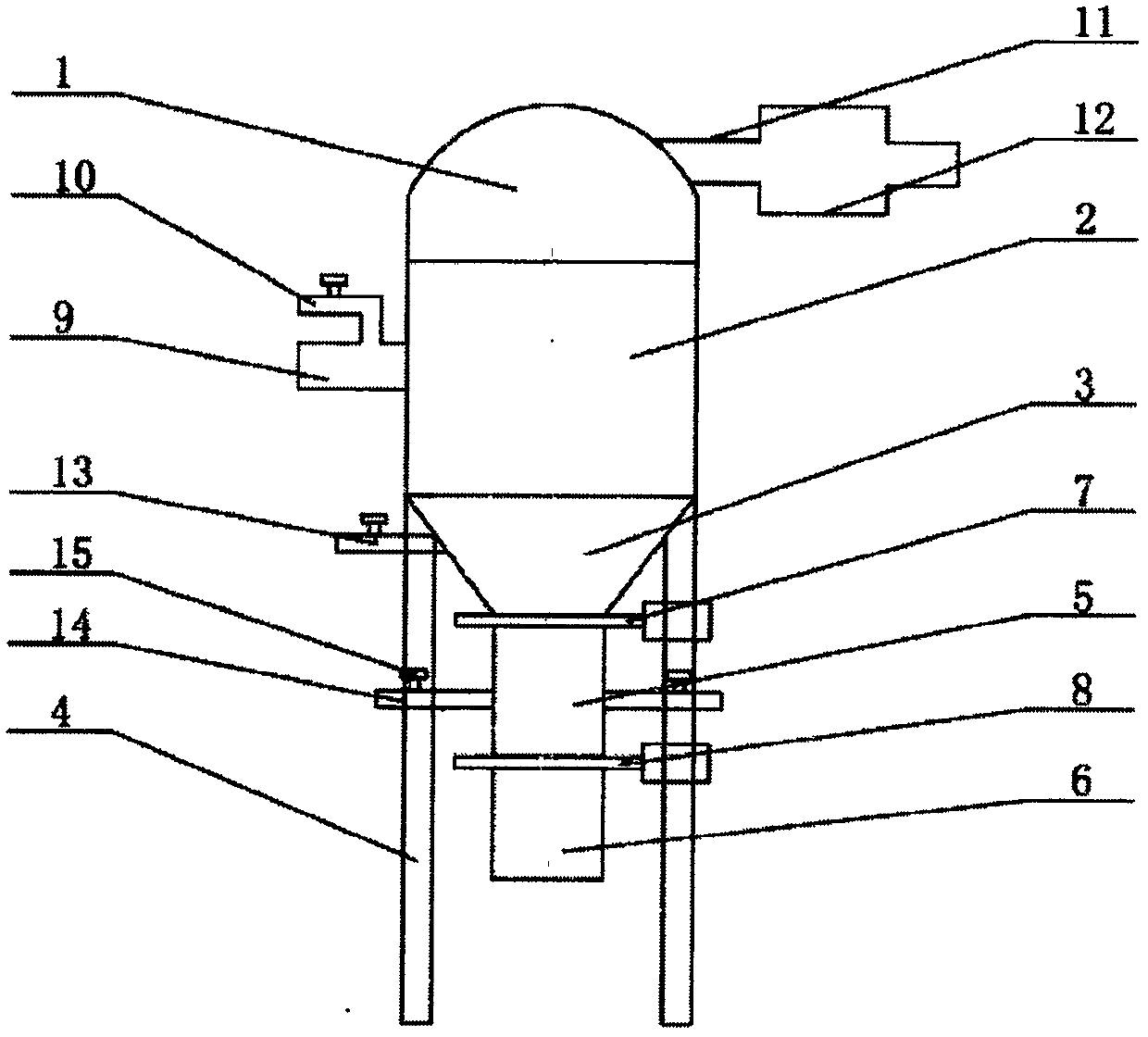

[0015] see figure 1 As shown, the technical solution adopted in this specific embodiment is: it includes equipment tank body 1, slurry inlet layer 2, sediment funnel layer 3, equipment support 4, sediment chamber 5, slag discharge port 6, No. 1 electric control valve 7, No. 2 electric control valve 8, pulp inlet pipe 9, pulp inlet dilution water pipe 10, pulp outlet pipe 11, high pressure pump 12, sediment dilution pipe 13, elutriation water pipe 14, the equipment tank 1 is connected to the upper end of the pulp inlet layer 2, The opening of the sediment funnel layer 3 is connected to the lower end of the slurry inlet layer 2, the upper end of the sediment chamber 5 is connected to the lower end of the sediment funnel layer 3 through the No. 1 electric control valve 7, and the lower end of the sediment chamber 5 is connected to the slag discharge through the No. 2 electric control valve 8 Port 6; the slurry inlet pipe 9 is connected to the middle of the slurry inlet layer 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com