Control method for producing 1,3-propanediol by substrate fed-batch fermentation on basis of growth and metabolism characteristics

A control method, propylene glycol technology, applied in fermentation and other directions, can solve problems such as difficulty in glycerin concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

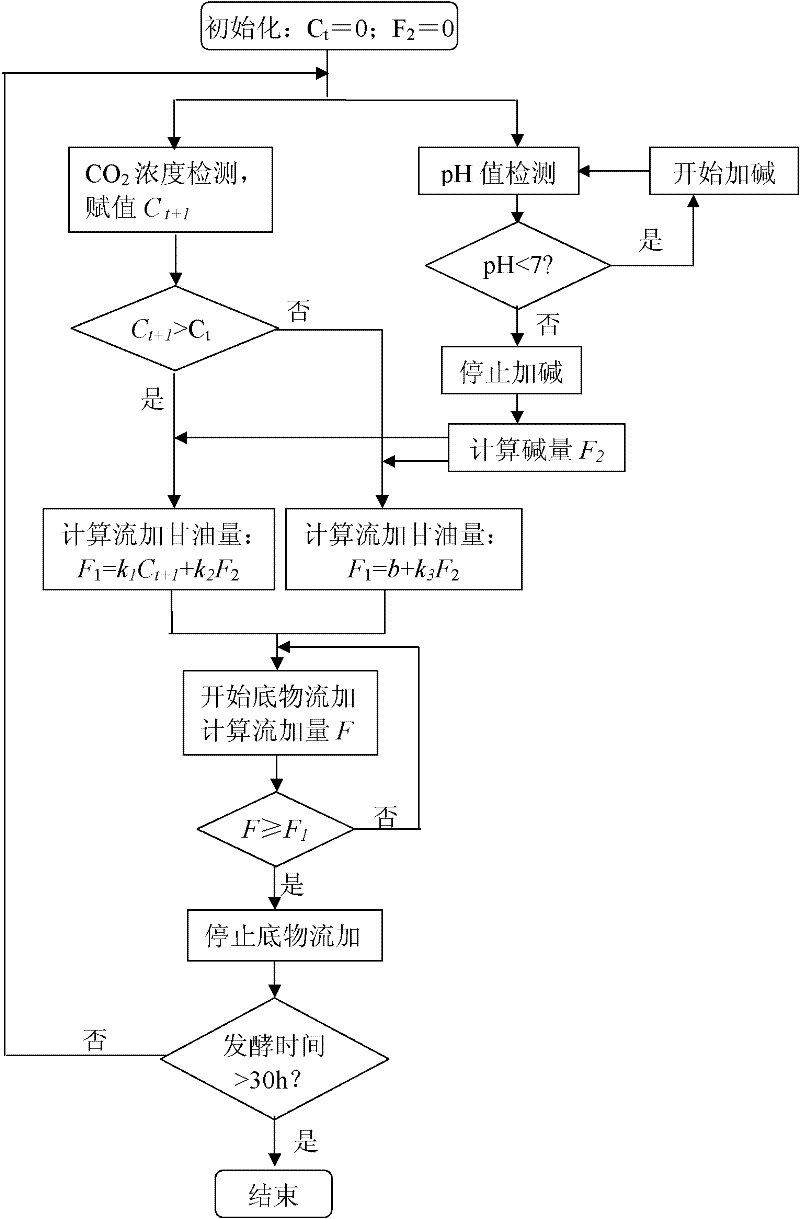

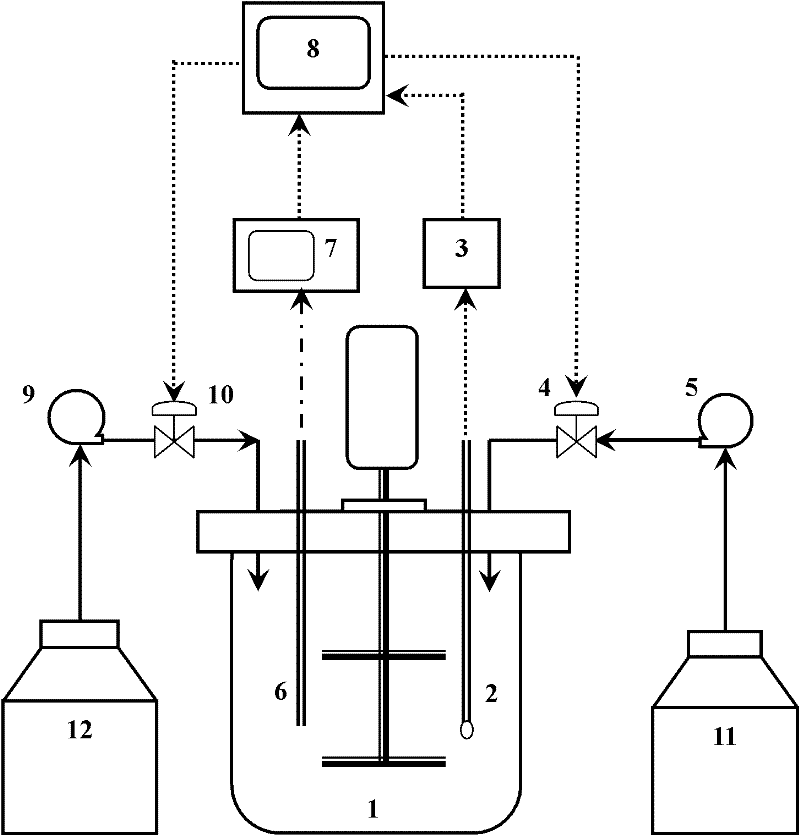

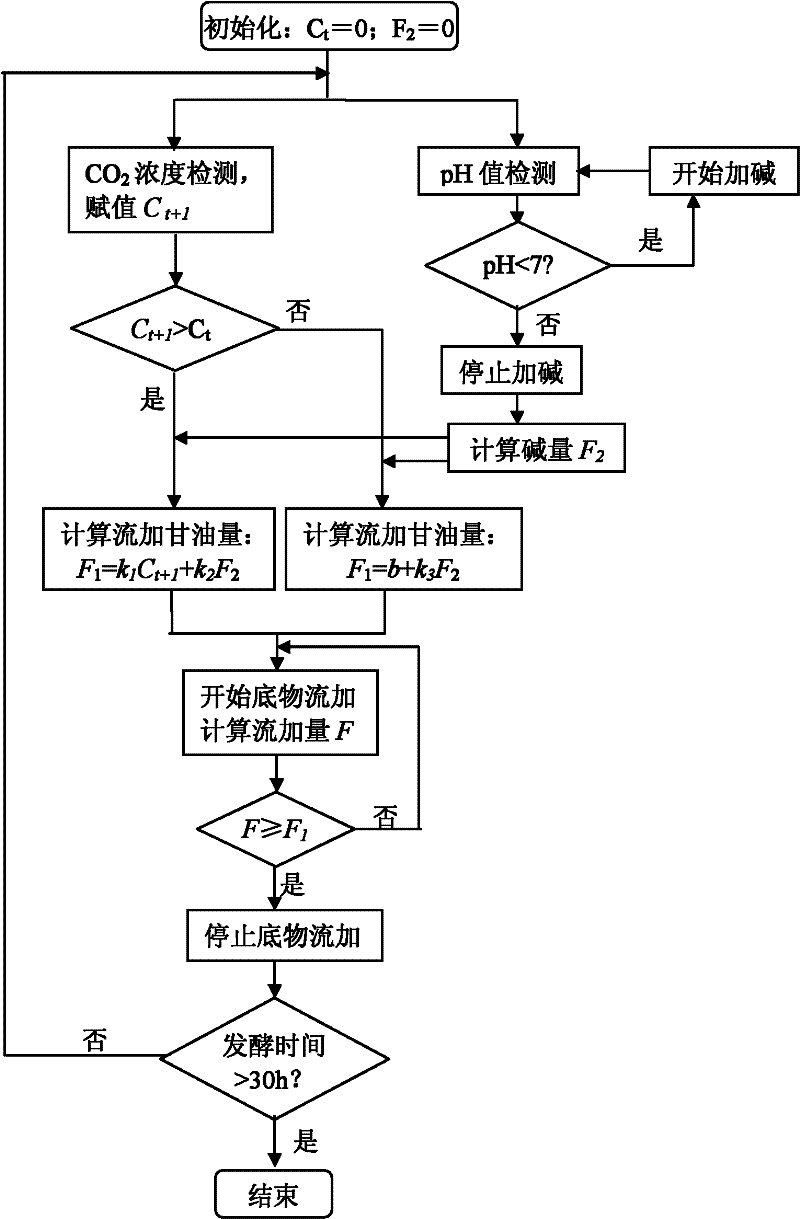

Method used

Image

Examples

Embodiment

[0058] 1) Bacterial species: Klebsiella pneumoniae (Klebsiella pneumoniae) CGMCC 2028

[0059] 2) Medium:

[0060] (1) Seed medium (g / L): Glycerol: 20, MgSO 4 ·7H 2 O: 0.2, KH 2 PO 4 : 1.3, (NH 4 ) 2 SO 4 : 2.0,K 2 HPO 4 ·3H 2 O: 4.56, yeast powder: 2, CaCO 3 :2. Trace element A: 2mL / L, Fe 2+ Solution: 1mL / L, Ca 2+ Solution: 1mL / L.

[0061] Trace element A (mg / L): ZnCl 2 : 70, MnCl 2 4H 2 O: 100, H 3 BO 3 : 60, CoCl 2 ·6H 2 O: 200, CuCl 2 ·6H 2 O: 20, NiCl 2 ·6H 2 O: 25, Na 2 MoO 4 2H 2 O: 5.

[0062] Fe 2+ Solution (L -1 ): FeSO 4 ·7H 2 O: 5g, HCl (12M): 4mL

[0063] Ca 2+ Solution (g / L): CaCl 2 :20.

[0064] (2) Fermentation medium (g / L): glycerol: 40, (NH 4 ) 2 SO 4 : 6.61, KH 2 PO 4 : 1.36, MgCl 2 ·6H 2 O: 0.26, CaCl 2 : 0.29, citric acid: 0.42, yeast powder: 1. Trace element B: 5mL / L.

[0065] Trace element B (g / L): ZnCl 2 : 0.68, MnCl 2 4H 2 O: 0.17, H 3 BO 3 : 0.06, CuCl 2 2H 2 O: 0.47, Na 2 MoO 4 2H 2 O: 0.005, Fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com