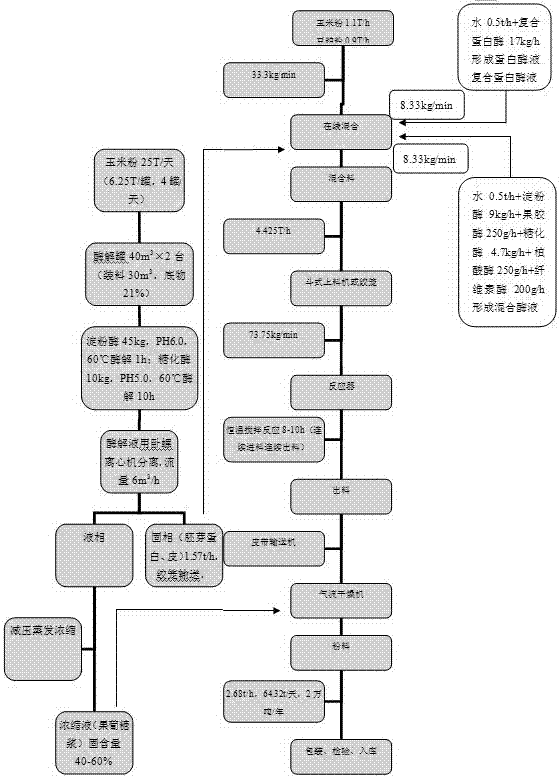

Functional biological feed production process

A technology of functional feed and raw materials, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of 4-5 large cement ponds, large floor area, substrate consumption, etc., to improve feed absorption Utilization, increased animal feed intake, effects of low nutrient resistance factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Laboratory preparation process of new functional feed

[0029] (1) Take 100g of 40mesh-60mesh corn flour, add water to 1000ml, make the substrate concentration 10%, raise the temperature to 50°C, adjust the pH to 5.0, add 700u of amylase, stir for 40min to enzymatically hydrolyze, until the starch is negative in the iodine test (brown), adjust the temperature to 55°C, pH 4.0, add 3500u glucoamylase, stir and saccharify for 6 hours, centrifuge to separate the slag liquid, and the liquid is concentrated by rotary evaporation to a solid content of about 35%, which is fructose syrup, slag sample (corn Germ and corn husk) separated for later use.

[0030] (2) Take 100g of 40mesh-60mesh corn flour, 90g of 40mesh-60mesh soybean meal powder and mix evenly, then add the slag in (1) and mix evenly.

[0031] (3) Take 76ml of water, divide it into two parts on average, take 0.36 g of compound protease (1398 neutral protease: 2709 alkaline protease = 1:2-5) and disperse a...

Embodiment 2

[0034] Example 2 Analysis of Nutrients in New Functional Feed

[0035]Carry out nutrient composition analysis in the novel functional feed prepared in Example 1, the determination method of peptide content refers to GB / T22492-2008 " soybean peptide powder " in the determination method of peptide content, peptide content is 6.67%; The determination of reducing sugar content refers to GB / T15038-2006 "Universal Analysis Methods for Wine and Fruit Wine", the reducing sugar titration method of Fehling's reagent, the reducing sugar content is 15.12%; the determination of urease activity refers to GB / T 8622-2006 "Determination of Urease Activity in Soybean Products for Feed" Method", the urease activity of the functional feed was 0.035U / g, which was 76.67% lower than that of the control group; the pectin was determined according to NY 82.11-1988 Juice Determination Method-Pectin Determination, the pectin content in the functional feed was 3.85%, which was 3.85% higher than that of th...

Embodiment 3

[0036] Example 3 Pilot-scale preparation process of new functional feed

[0037] (1) Take 100 kg of 40-mesh corn flour, put it into the reaction kettle, add 660 kg of water to make the substrate concentration 15%, raise the temperature to 55°C, adjust the pH to 6.0, add 1.4 million u of amylase, and stir for about 60 minutes to enzymatically hydrolyze , until the iodine test shows that the starch is negative (brown), adjust the temperature to 60°C, pH 4.5, add 7 million u of glucoamylase, stir and enzymolyze for 10 hours, centrifuge, and concentrate the liquid to a solid content of 45% by a vacuum evaporator, that is, the fruit Glucose syrup and solid phase slag are used for the next step.

[0038] (2) Take 100kg of 40-mesh corn flour and 100kg of 40-mesh soybean meal and mix them evenly, then mix them into the solid phase slag in 1, and mix them evenly.

[0039] (3) Take water, the mass of which is 50% of the total mass of corn flour and soybean meal, that is, 100kg, and div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com