Pin-free positioning automatic expansion and shrinkage drilling production method

A production method and technology for positioning holes, which are used in electrical components, printed circuit manufacturing, printed circuits, etc., can solve problems such as drilling deviation of production boards, and achieve the effect of improving alignment accuracy and reducing the scrap rate of drilling deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The overall process of the production method of automatic expansion and contraction drilling without Pin positioning: area division → area symbol design → X-Ray punching → CCD drilling, the specific steps are as follows:

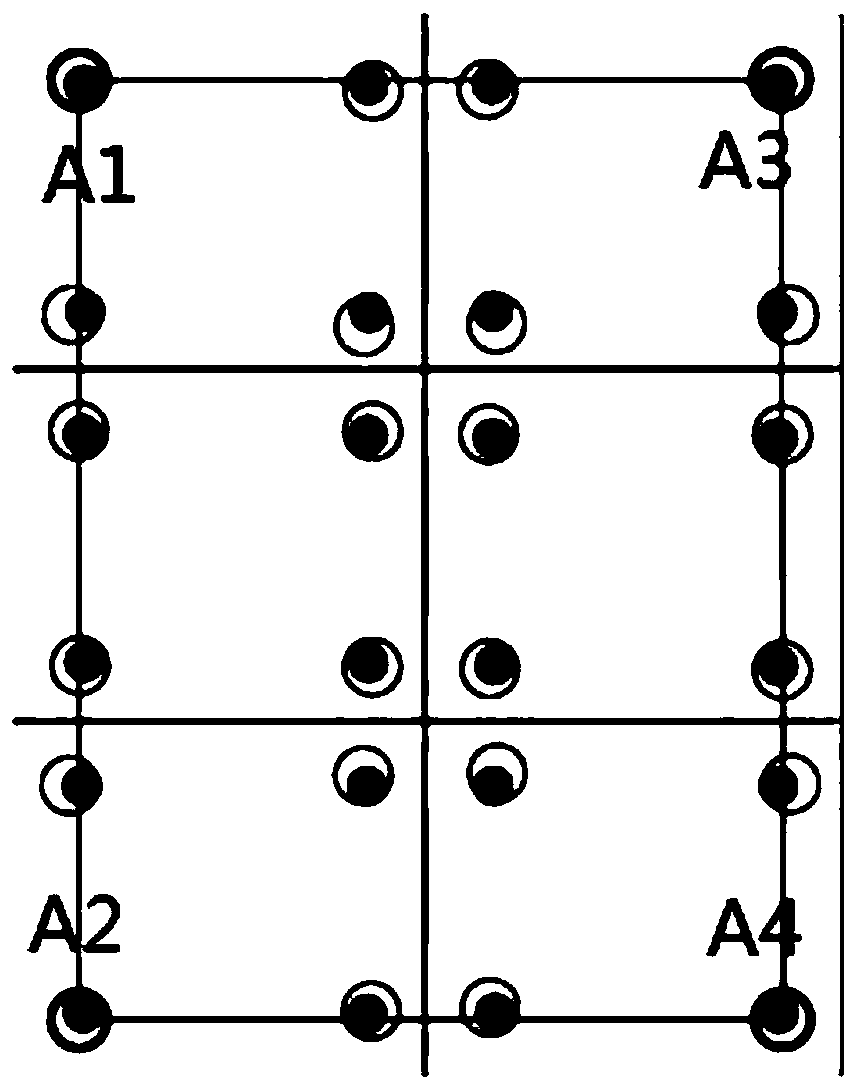

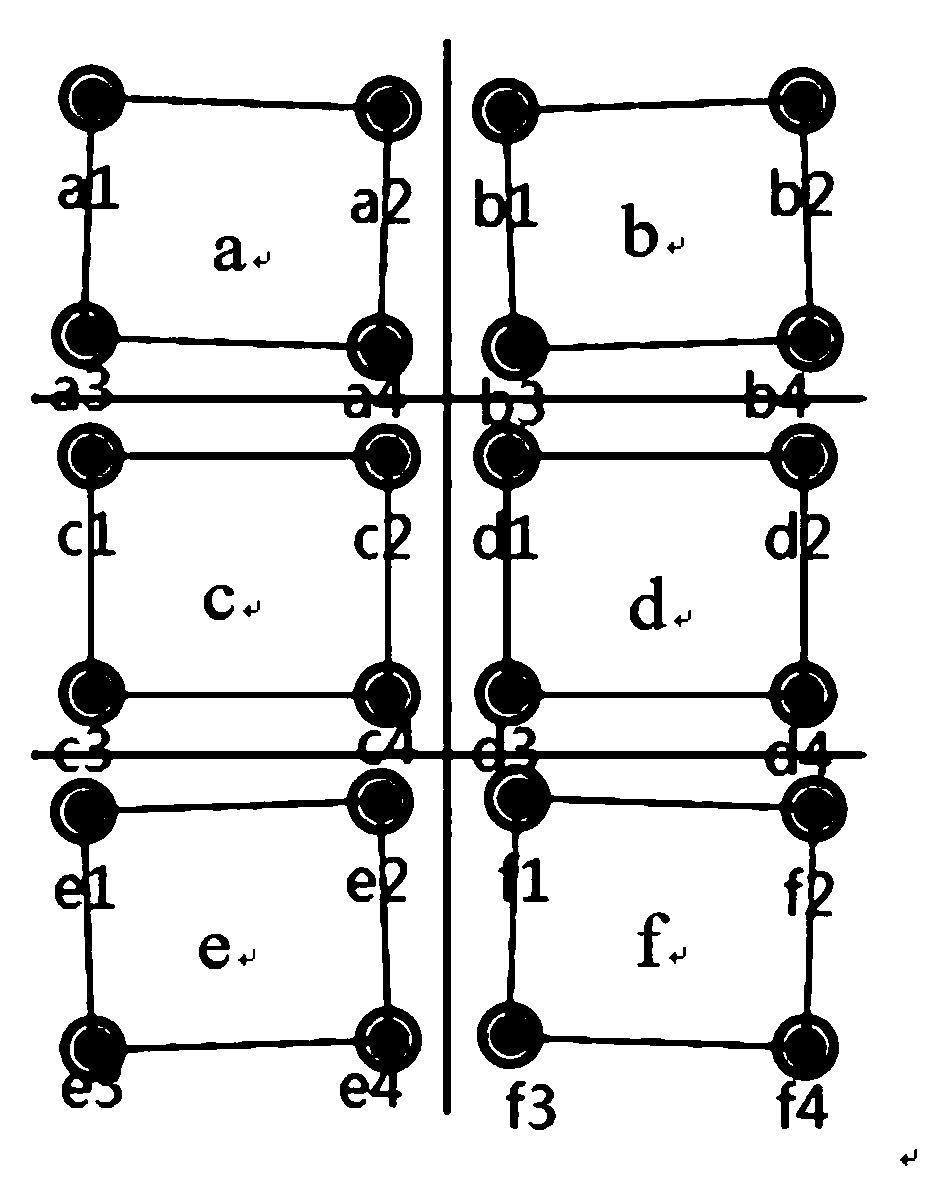

[0017] Step 1: When the production board has alignment requirements (such as alignment requirements ≤ 6mil), it is divided into regions. Such as figure 2 In this embodiment, the production board is divided into six areas a, b, c, d, e, and f, and the smaller the area division, the higher the alignment accuracy.

[0018] Step 2: Add a symbol design to the inner layer graphics at the four corners of each area (symbol is the target designed in the inner layer PCB, the target is the copper pad, and the design is on the short side, a total of 4, X-Ray can recognize the copper pad and place it on the copper pad The position of the pad is punched), and then through the pressing process X-Ray to identify and punch, and the symbol design position is punched ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com