Waste gas treatment device for power plant

A waste gas treatment device and waste gas treatment technology, which are used in gas treatment, transportation and packaging, dispersed particle filtration, etc., can solve the problems of no secondary filtration, low filtration efficiency, low adsorption efficiency, etc., so as to improve treatment efficiency and treatment efficiency. effect, high cleanliness, and the effect of improving the filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

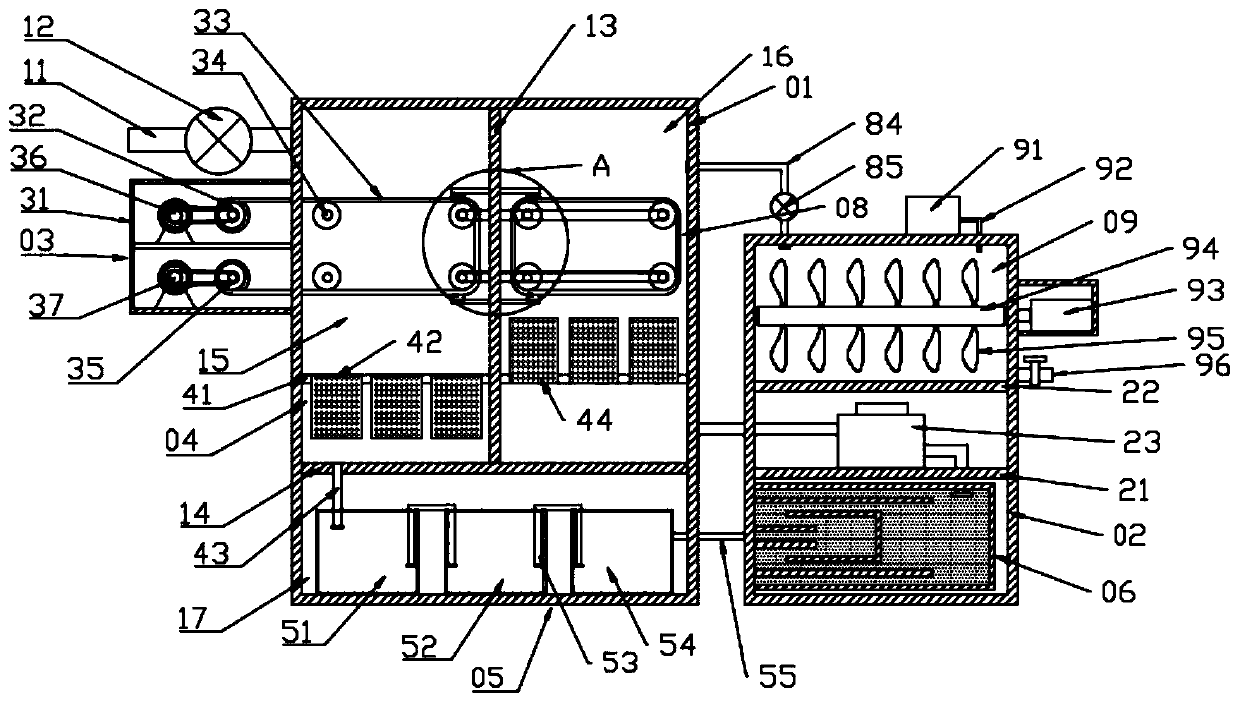

[0027] see Figure 1~4 , in an embodiment of the present invention, an exhaust gas treatment device for a power plant includes a first exhaust gas treatment box 01 and a second exhaust gas treatment box 02, and the first exhaust gas treatment box 01 communicates with the second exhaust gas through a third gas duct 55 The treatment box 02 is connected to transfer the gas in the first exhaust gas treatment box 01 to the second exhaust gas treatment box 02. The first exhaust gas treatment box 01 is used to treat the exhaust gas, and the second exhaust gas treatment box 02 is used to treat At the same time, the second exhaust gas treatment box 02 communicates with the first exhaust gas treatment box 01 through the second gas duct 24, and then the gas adsorbed in the second exhaust gas treatment box 02 is processed again, and then Improve the gas treatment effect, make the gas cleaner, and have very good practicability.

[0028] Further, a first partition 13 and a second partition...

Embodiment 2

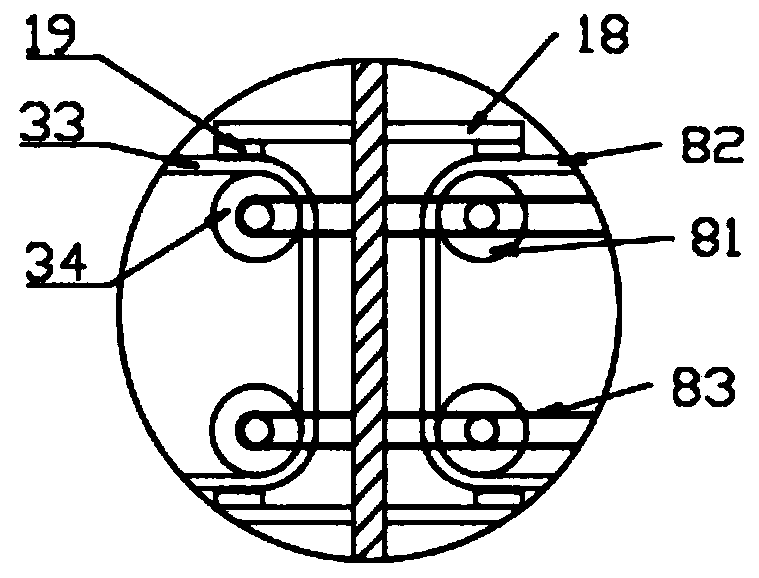

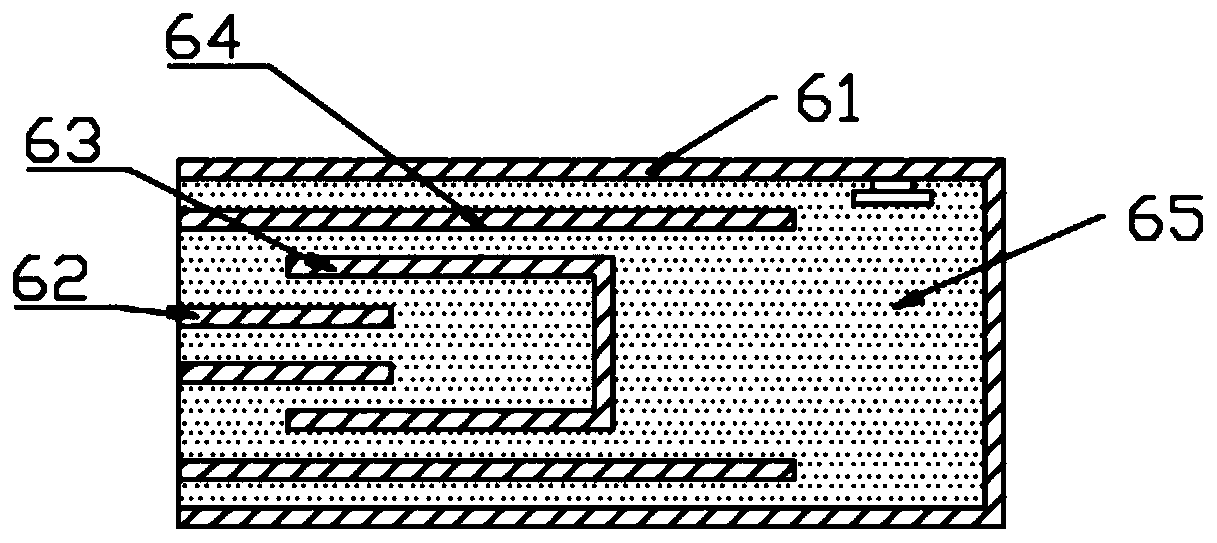

[0039] An exhaust gas treatment device for a power plant, the first exhaust gas treatment box 01 and the second exhaust gas treatment box 02 are connected through the third gas duct 55 and the second gas duct 24, and then the treated exhaust gas can be transferred to Adsorption is carried out in the second exhaust gas treatment box 02, and after the adsorption is completed, it enters the first exhaust gas treatment box 01 for secondary adsorption, and finally enters the first exhaust gas treatment box 01 for drying. This structure improves the efficiency of the exhaust gas. The treatment efficiency and treatment effect make the exhaust gas cleanliness higher; by setting the first filter assembly 03 and the second filter assembly 04, it can filter the exhaust gas, and can remove dust and large particles of impurities in the exhaust gas, while The first filter screen 33 and the second filter screen 82 can be driven to rotate by the first drive motor 36 and the second drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com