Remediation tank for heavy metal contaminated soil

A technology for polluted soil and heavy metals, applied in the restoration of polluted soil, solid separation, sieving and other directions, can solve the problems of soil damage to soil structure, secondary pollution, soil quality threat, etc., to achieve enhanced solubility, convenient maintenance, The effect of easy digging operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Dissolve citric acid monohydrate in water to prepare 20mmol / L citric acid solution;

[0047] Dissolve trisodium ethylenediamine disuccinate in water to prepare 20mmol / L trisodium ethylenediamine disuccinate solution;

[0048] adding the rhamnolipid into water, stirring evenly to obtain a 10g / L rhamnolipid solution;

[0049] Mix citric acid solution, trisodium ethylenediamine disuccinate solution and rhamnolipid solution uniformly at a volume ratio of 1:0.5:0.5 to obtain composite rinse agent A.

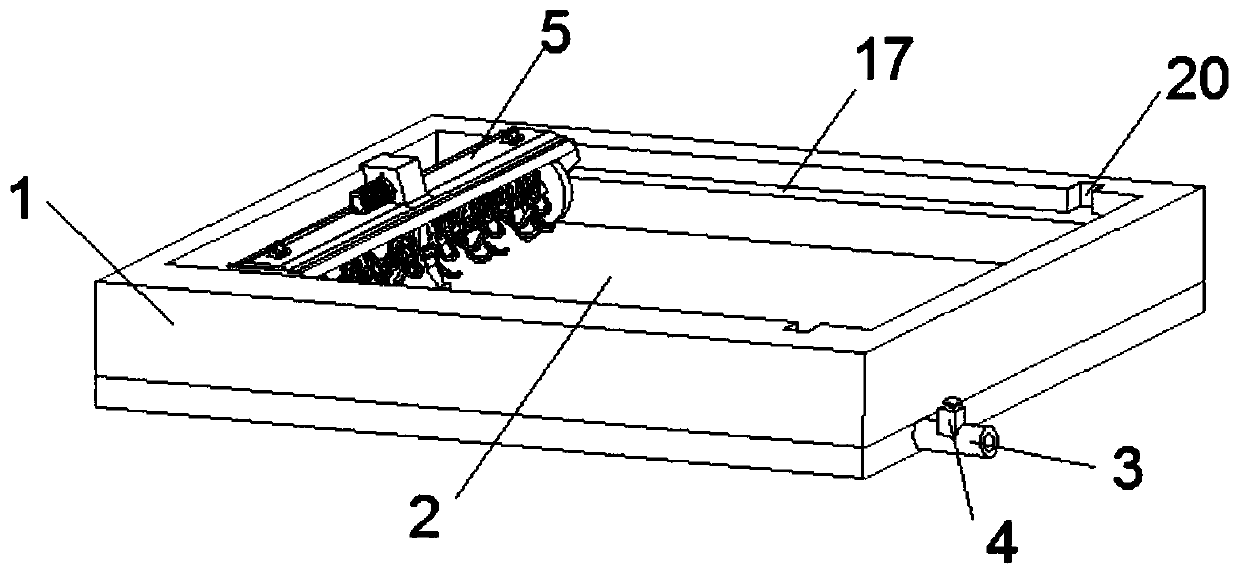

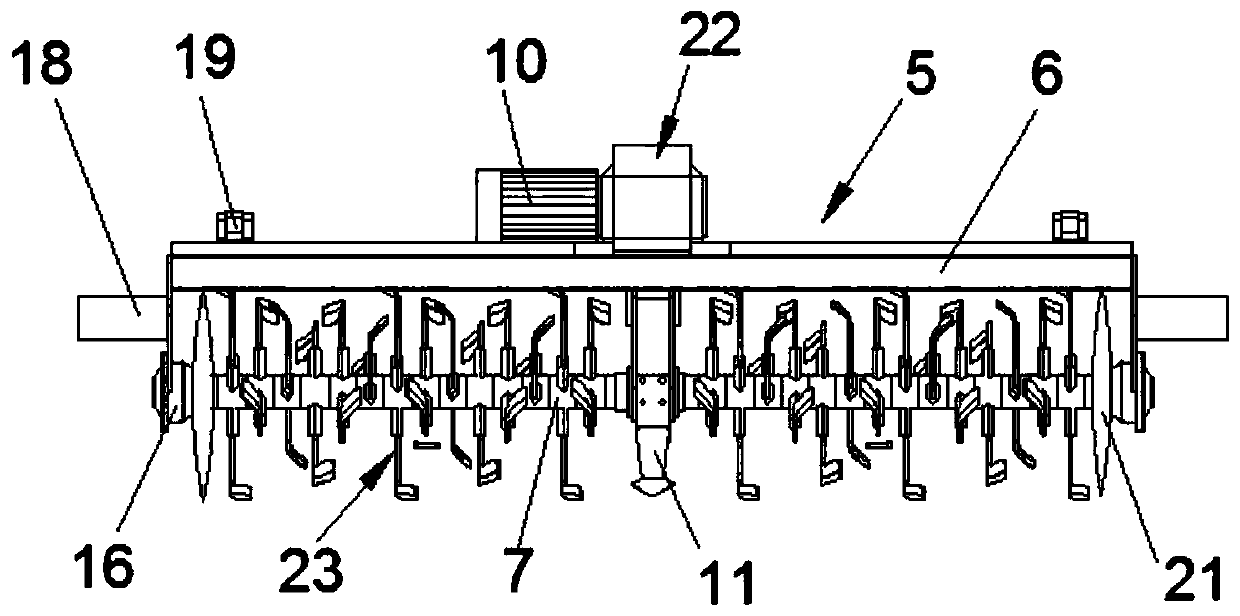

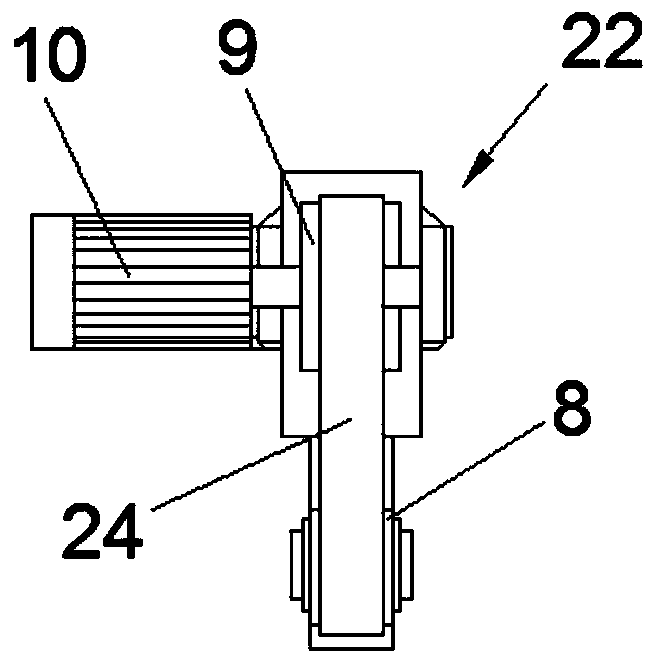

[0050] Add the polluted soil that has been sieved to remove the gravel by the filter screen into the repair pool, add the rinse agent A into the repair tank according to the ratio of 1kg soil to 3L rinse agent, fully mix the contaminated soil and rinse agent A, and Stir the soil continuously, and discharge the eluent A out of the repair pool through the drain pipe 3 after 6 hours. The discharged eluent A is collected and then treated centrally. After the eluent A is discharged...

Embodiment 2

[0052] Dissolve oxalic acid in water to prepare a 30mmol / L oxalic acid solution;

[0053] Dissolve disodium edetate in water to prepare a 20 mmol / L disodium edetate solution;

[0054] Adding sophorolipids into water and stirring evenly to obtain a 10g / L sophorolipid solution;

[0055] Mix oxalic acid solution, edetate disodium solution and sophorolipid solution uniformly at a volume ratio of 1:1:2 to obtain composite rinse agent B.

[0056] Add the polluted soil that has been sieved to remove the gravel by the filter screen into the restoration pool, add the eluent B to the restoration pool at the ratio of 1kg of soil to 5L of the eluent, fully mix the contaminated soil and the eluent B, and Stir the soil continuously, and discharge the eluent B out of the repair pool through the drain pipe 3 after 6 hours. The discharged eluent B is collected and then treated centrally. After the eluent B is discharged, take a soil sample to test the zinc, copper, nickel, Changes in the con...

Embodiment 3

[0058] Dissolve acetic acid in water to prepare 20mmol / L acetic acid solution;

[0059] Dissolve tetrasodium glutamic acid N,N-diacetate in water to prepare 30mmol / L tetrasodium glutamate N,N-diacetate;

[0060] adding trehalolipid into water, stirring evenly to obtain 20g / L trehalolipid solution;

[0061] Acetic acid solution, tetrasodium glutamic acid N,N-diacetate solution and trehalolipid solution were uniformly mixed at a volume ratio of 1:2:0.5 to obtain a composite eluent C.

[0062] Add the polluted soil that has been sieved to remove the gravel by the filter screen into the restoration pool, add the eluent C into the restoration pool according to the ratio of 1kg of soil to 3L of eluent C, fully mix the contaminated soil and eluent C, and Stir the soil continuously, and discharge the eluent C out of the repair pool through the drain pipe 3 after 6 hours. The discharged eluent C is collected and treated centrally. After the eluent C is discharged, take a soil sample t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com