Composite leather flame compounding machine with rapid cooling function and working method thereof

A flame laminator and rapid cooling technology, applied in flat products, household appliances, other household appliances, etc., can solve the problems of affecting leather quality, low processing efficiency, poor product quality, etc., to achieve convenient use, high production efficiency, cooling fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

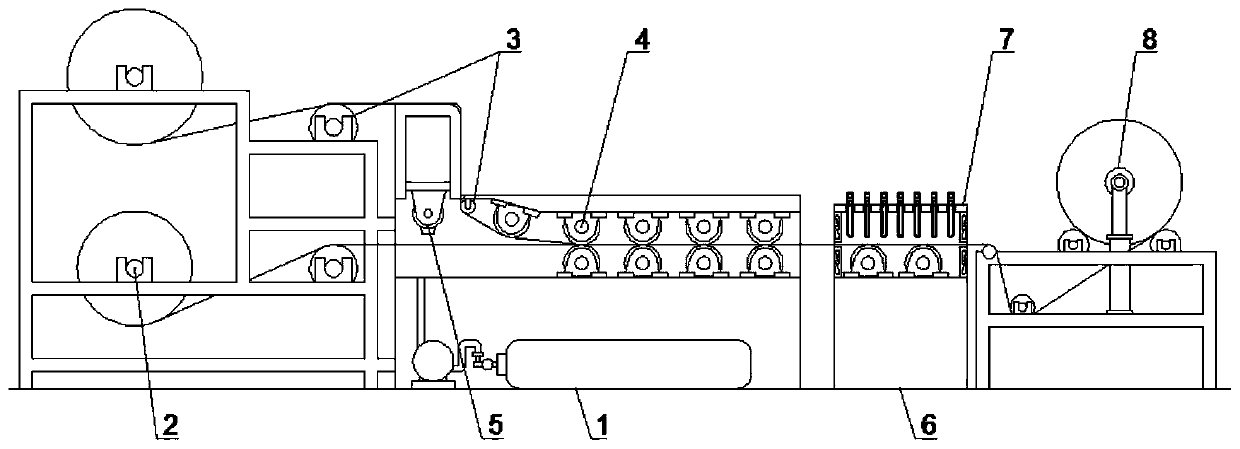

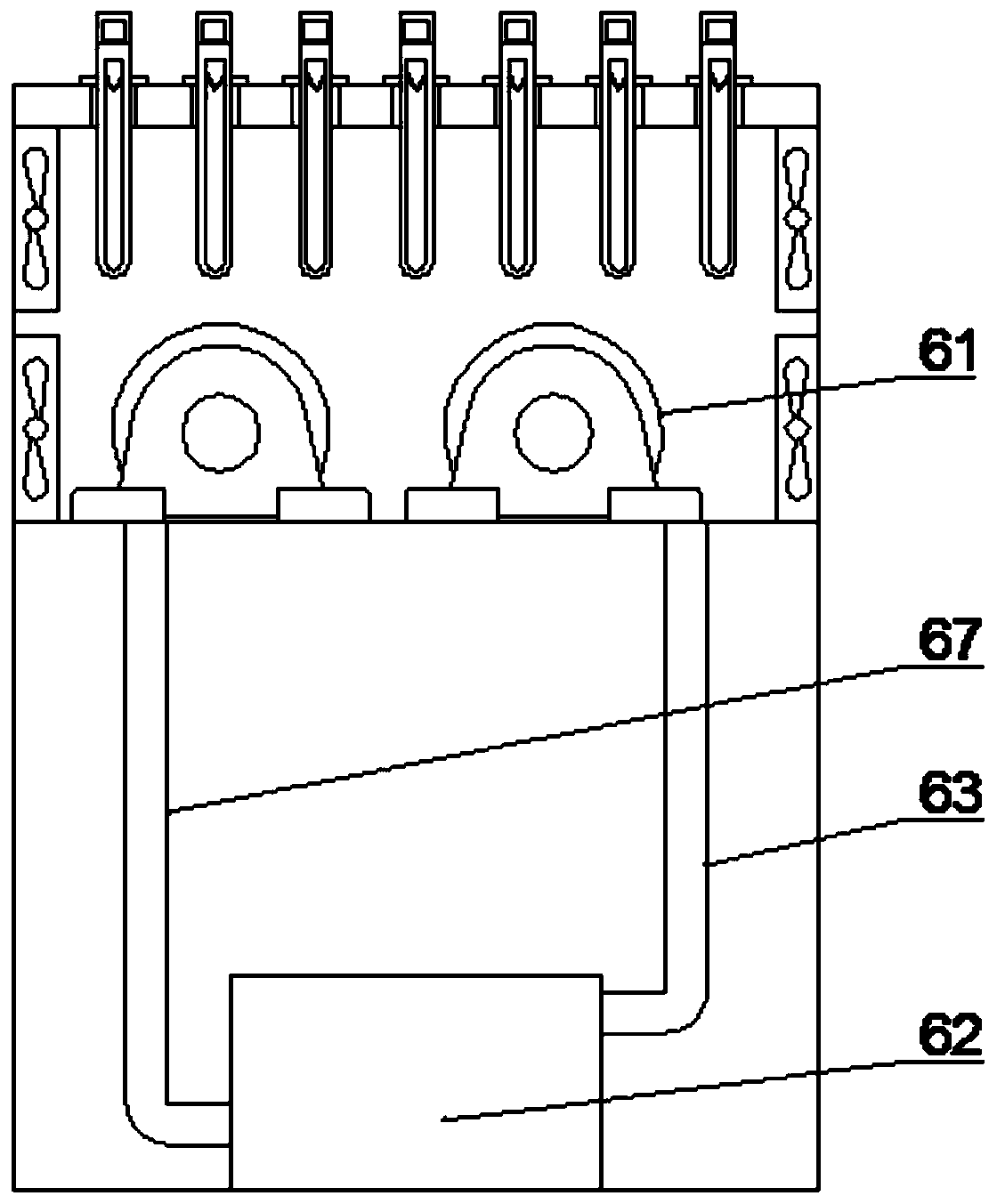

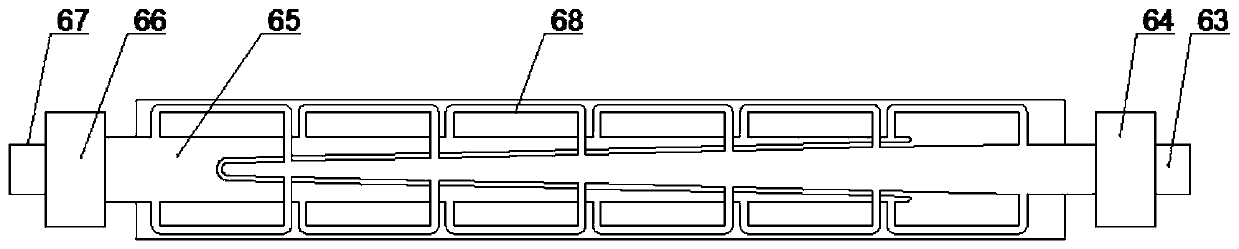

[0043] Such as Figure 1-6A fast-cooling compound leather flame compounding machine is shown, including: a base 1, a feeding roller 2, a turning roller 3, a pressing roller 4, a flame injection mechanism 5, a cooling roller 6, an air cooling channel 7 and a storage material Roller 8, the base 1 is provided with a feeding roller 2, and one side of the feeding roller 2 is provided with a turning roller 3, and the turning roller 3 is fixedly arranged on the base 1, and the turning roller 3 is far away from the upper One side of the material roller 2 is provided with a pressing roller 4, and the pressing roller 4 is fixedly arranged on the base 1, and the side of the pressing roller 4 away from the steering roller 3 is provided with a cooling roller 6, and the cooling roller 6 Fixedly installed on the base 1, the cooling roller 6 is provided with an air-cooling mechanism 7, the air-cooling mechanism 7 covers the cooling roller 6, and the side of the cooling roller 6 away from the ...

Embodiment 2

[0058] Such as Figure 1-4 A fast-cooling compound leather flame compounding machine is shown, including: a base 1, a feeding roller 2, a turning roller 3, a pressing roller 4, a flame injection mechanism 5, a cooling roller 6, an air cooling channel 7 and a storage material Roller 8, the base 1 is provided with a feeding roller 2, and one side of the feeding roller 2 is provided with a turning roller 3, and the turning roller 3 is fixedly arranged on the base 1, and the turning roller 3 is far away from the upper One side of the material roller 2 is provided with a pressing roller 4, and the pressing roller 4 is fixedly arranged on the base 1, and the side of the pressing roller 4 away from the steering roller 3 is provided with a cooling roller 6, and the cooling roller 6 Fixedly installed on the base 1, the cooling roller 6 is provided with an air-cooling mechanism 7, the air-cooling mechanism 7 covers the cooling roller 6, and the side of the cooling roller 6 away from the...

Embodiment 3

[0063] Such as figure 1 , 5 A kind of rapid cooling composite leather flame compounding machine shown in and 6 comprises: base 1, feeding roller 2, turning roller 3, pressing roller 4, flame injection mechanism 5, cooling roller 6, air-cooled channel 7 and Storage roller 8, the base 1 is provided with a feed roller 2, one side of the feed roller 2 is provided with a turning roller 3, and the turning roller 3 is fixedly arranged on the base 1, and the turning roller 3 The side away from the feeding roller 2 is provided with a pressing roller 4, and the pressing roller 4 is fixedly arranged on the base 1, and the side of the pressing roller 4 away from the steering roller 3 is provided with a cooling roller 6, and the cooling roller 4 The roller 6 is fixedly arranged on the base 1, the cooling roller 6 is provided with an air-cooling mechanism 7, the air-cooling mechanism 7 covers the cooling roller 6, and the side of the cooling roller 6 away from the pressing roller 4 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com