Environment-friendly treatment method for cellulose evaporation waste liquid

An environmental protection treatment and cellulose technology, which is applied in the process of wastewater treatment, filtration treatment, sedimentation treatment, etc., can solve problems such as increasing treatment pressure, and achieve the effect of reducing treatment pressure, increasing profit points, and solving the pressure of evaporating residual liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

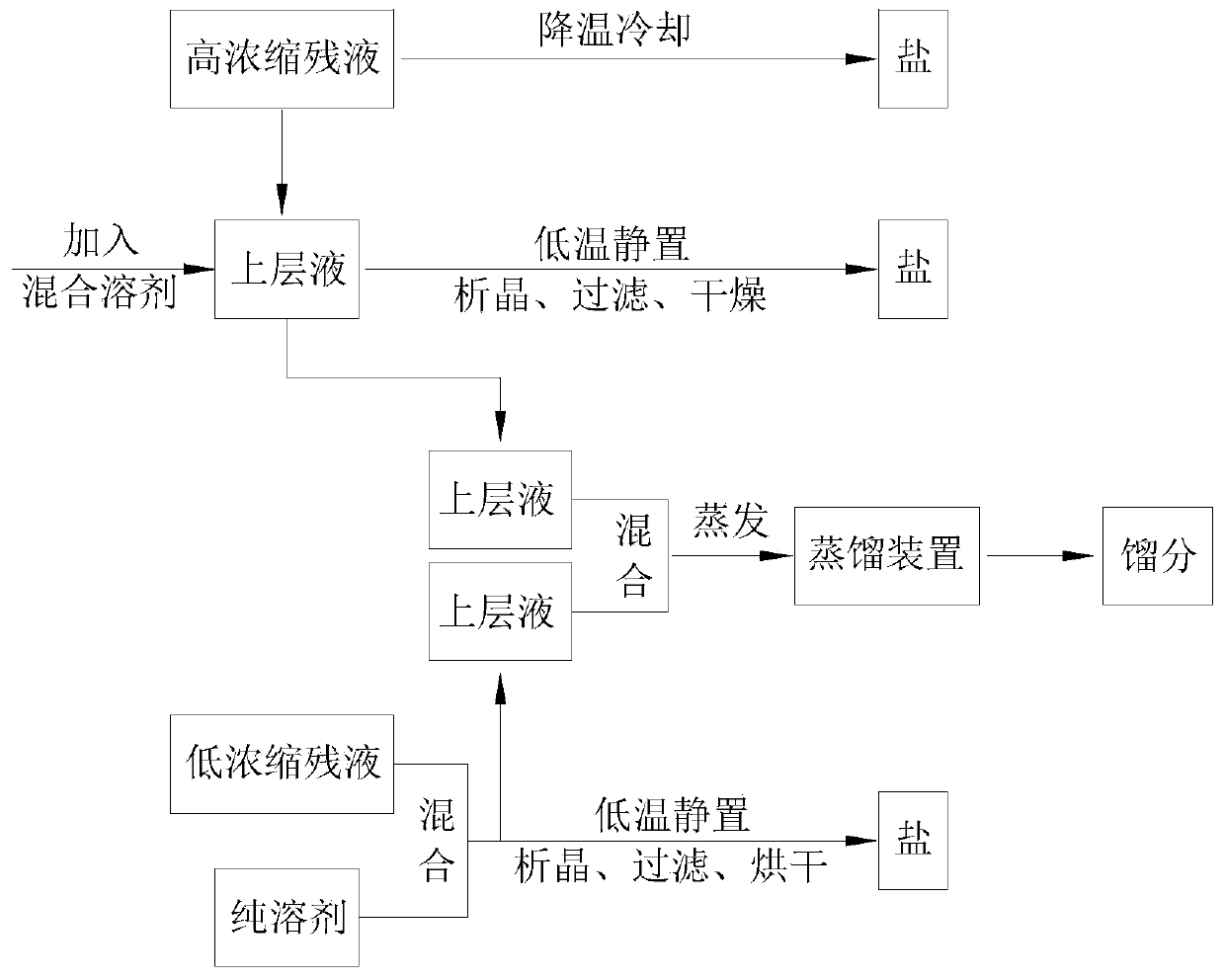

[0021] In order to enable those skilled in the art to better understand the application process, the following will be combined with the attached figure 1 , to clearly and completely describe the process in the embodiment of the present application.

[0022] An environmentally friendly treatment method for cellulose evaporation waste liquid, the evaporation waste liquid includes highly concentrated raffinate and low concentrated raffinate, comprising the following steps:

[0023] (1) The highly concentrated raffinate is cooled down, the temperature is lowered to 20°C and then left to stand, the first organic salt is precipitated through crystallization and recovered, and the first upper layer liquid is kept in the first storage tank; crystallization refers to when When the substance is in a non-equilibrium state, another phase will be precipitated, and this phase will be precipitated in the form of crystals.

[0024] (2) Add a mixed solvent containing organic alcohols to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com