Manufacturing method of resin for polyolefin breathable membrane

A manufacturing method and a technology for a breathable film, which are applied in the field of manufacturing resins for polyolefin breathable films, can solve problems such as unsatisfactory resin fluidity, and achieve the effects of good flow performance, uniform air permeability and good tensile force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

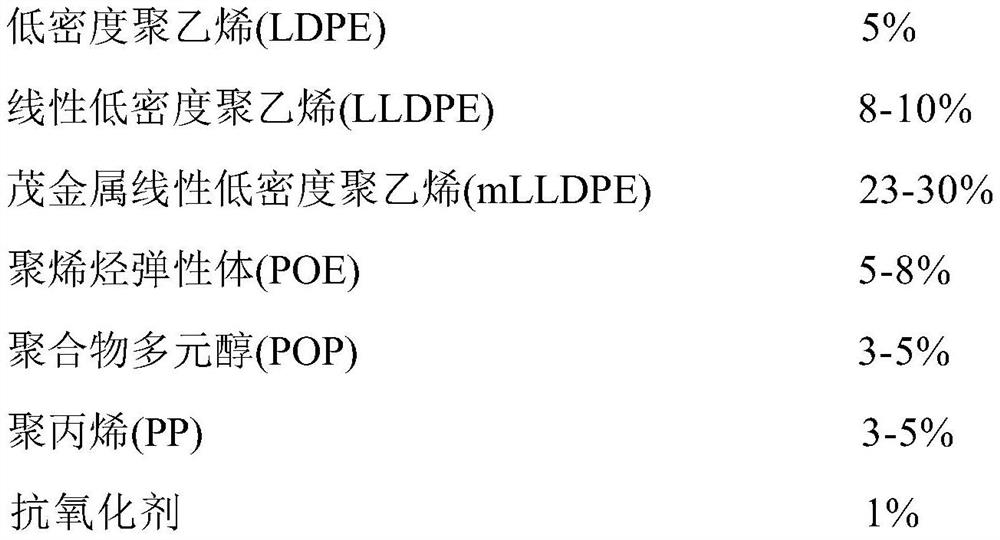

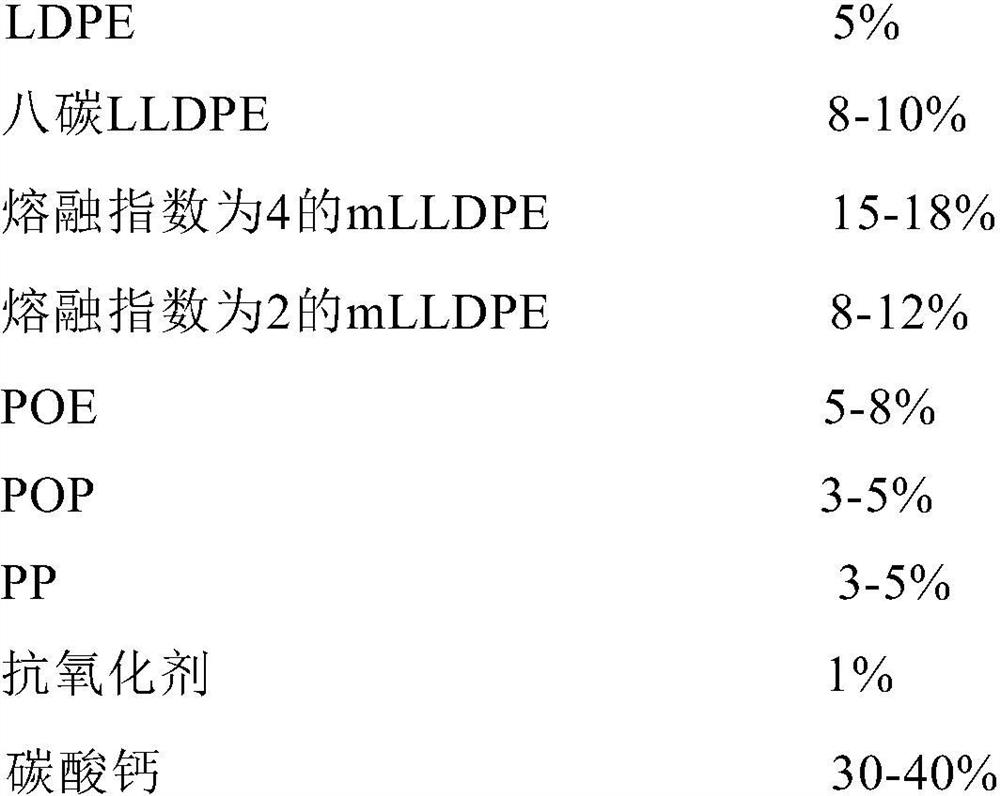

[0036] Example 1 Resin for polyolefin breathable film

[0037] Source of raw materials: LDPE, eight-carbon LLDPE, mLLDPE (MI is 4), mLLDPE (MI is 2), POE, POP, PP, antioxidants are all commercially available.

[0038] Calcium carbonate with a particle size of 1.5-3 microns is selected and the content exceeds 80% of the total weight; D97<5 microns.

[0039] 1. The formula of resin for polyolefin breathable film is as follows:

[0040]

[0041] 2. Manufacture of resin particles for polyolefin breathable film

[0042] 2.1. Put 25kg of calcium carbonate particles in a high-speed kneader, the rotation speed is 1000rpm, the temperature is 105±2°C, and the kneading is performed for 20 minutes. Then add antioxidant, knead for 15 minutes, then add LDPE, eight-carbon LLDPE, mLLDPE (MI is 4), mLLDPE (MI is 2), POE, POP, PP, add in proportion, mix for 5 minutes and then enter the pressurized dense After mixing at 135±3℃ for 10 minutes in the mill, it is placed in a twin-roll rubber ...

Embodiment 3

[0059] Example 3 Preparation of the breathable film of the present invention

[0060] The resin particles for the polyolefin breathable film produced in Example 1 were used.

[0061]Add the resin pellets to a breathable film extruder; in the extruder, the screw is heated to 240°C, then the pellets are melted and extruded to obtain a film with a thickness of 0.4 mm; the heating ring in the oven is heated to 80°C, and a blower is used to After heating, the air is evenly blown to the surface of the extruded film, so that the film is heated and then stretched. The speed of the first stretch is 37m / min, the speed of the second stretch is 42.5m / min, the speed of the third stretch is 50m / min, the speed of the fourth stretch is 58m / min, and the speed of the fifth stretch is 68m / min. The stretch ratio is 1.84 times. The heated film is stretched by the speed difference, and the polyethylene in the film is stretched. After the polyethylene around the calcium carbonate is stretched, in...

Embodiment 4

[0065] Example 4 Performance test of breathable film

[0066] Various properties (for example, gram weight, tensile strength, elongation, water pressure resistance, moisture permeability, air permeability, blood pressure test seconds, temperature), and the comparison results are shown in Table 1 or Table 2 below.

[0067] The following signs 1, 2, 3, 4, and 5 represent the test points from left to right (horizontal) on the same film; 1 is the leftmost test point; 5 is the rightmost test point.

[0068] Table 1 Test results of the breathable film of the present invention

[0069]

[0070] Table 2 compares the test results of breathable membranes

[0071]

[0072]

[0073] in conclusion:

[0074] 5.1. It can be seen from the test results of the above-mentioned Wangyan type air permeability instrument: the air permeability of the comparative air permeability film is not uniform: the maximum value reaches 27000, while the minimum value is only 7500, the difference betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com