Glue and preparation method thereof

A glue, S12 technology, applied in adhesives, adhesive types, amide/imide polymer adhesives, etc., can solve problems such as pungent taste, formaldehyde volatilization, harmful to human health, etc., to improve stability, Improve the strength, the effect of high glue quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

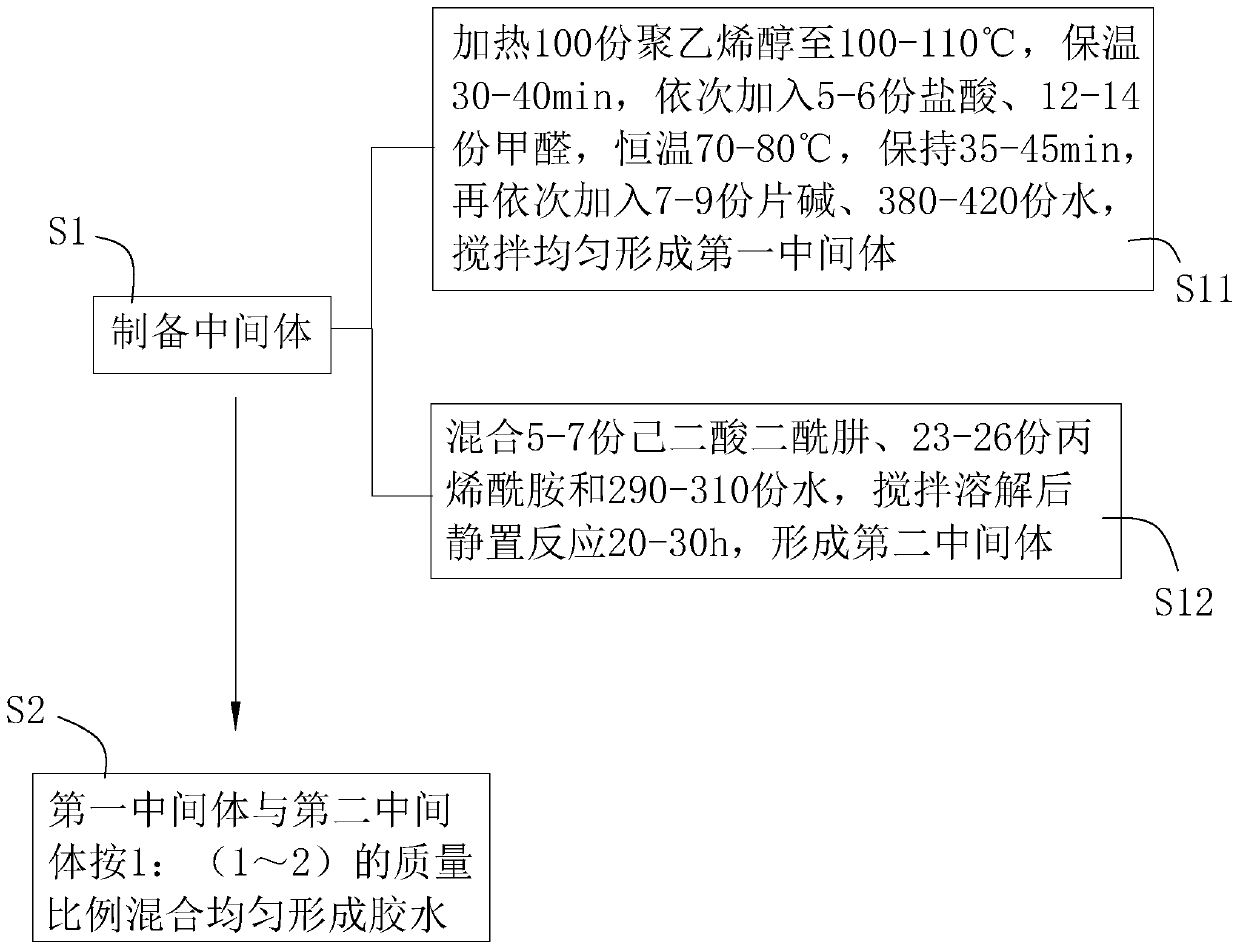

[0051] refer to figure 1 , is a kind of glue preparation method disclosed by the present invention, comprises the following steps:

[0052] S1. Preparation of intermediates, including:

[0053] S11. Add 100kg of polyvinyl alcohol into the first stirred tank, heat the polyvinyl alcohol to 100°C, keep it warm for 40min, then add 5kg of hydrochloric acid and 12kg of formaldehyde in turn, keep the temperature at 70°C, keep it for 45min, then add 7kg of caustic soda and 380kg of water in turn , stirring evenly to form the first intermediate, and naturally cooling to room temperature;

[0054] S12. Add 5kg of adipic acid dihydrazide, 23kg of acrylamide, and 290kg of water into the second stirred tank, stir and dissolve, then leave to react for 20h to form the second intermediate;

[0055] S2. Add the first intermediate and the second intermediate to the third stirred tank, the mass ratio of the first intermediate and the second intermediate is 1:1, the rotation speed is 15r / min, a...

Embodiment 2

[0057] refer to figure 1 , is a kind of glue preparation method disclosed by the present invention, comprises the following steps:

[0058] S1. Preparation of intermediates, including:

[0059] S11. Add 100kg of polyvinyl alcohol into the first stirred tank, heat the polyvinyl alcohol to 110°C, keep it warm for 30min, then add 5kg of hydrochloric acid and 12kg of formaldehyde in turn, keep the temperature at 80°C, keep it for 35min, then add 7kg of caustic soda and 380kg of water in turn , stirring evenly to form the first intermediate, and naturally cooling to room temperature;

[0060] S12. Add 5kg of adipic acid dihydrazide, 23kg of acrylamide, and 290kg of water into the second stirred tank, stir and dissolve, then leave to react for 30h to form the second intermediate;

[0061] S2. Add the first intermediate and the second intermediate to the third stirred tank, the mass ratio of the first intermediate and the second intermediate is 1:1, the rotation speed is 15r / min, a...

Embodiment 3

[0063] refer to figure 1 , is a kind of glue preparation method disclosed by the present invention, comprises the following steps:

[0064] S1. Preparation of intermediates, including:

[0065] S11. Add 100kg of polyvinyl alcohol into the first stirred tank, heat the polyvinyl alcohol to 105°C, keep it warm for 35min, then add 5kg of hydrochloric acid and 12kg of formaldehyde in turn, keep the temperature at 75°C, keep it for 40min, then add 7kg of caustic soda and 380kg of water in turn , stirring evenly to form the first intermediate, and naturally cooling to room temperature;

[0066] S12. Add 5kg of adipic acid dihydrazide, 23kg of acrylamide, and 290kg of water into the second stirred tank, stir and dissolve, then leave to react for 25h to form the second intermediate;

[0067] S2. Add the first intermediate and the second intermediate to the third stirred tank, the mass ratio of the first intermediate and the second intermediate is 1:1, the rotation speed is 15r / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com