Assembled anode for electrochemical reaction to synthesize stannous octoate, and assembling method thereof

A stannous octoate, chemical reaction technology, applied in the direction of electrolysis components, electrode shape/type, electrolysis process, etc., can solve the problems of increasing the invalid weight of the anode plate, increasing the weight of the anode plate, increasing the residual electrode rate of electrolysis, etc., to eliminate the The effect of hidden danger of production failure, reduction of invalid weight, and reduction of residual pole rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

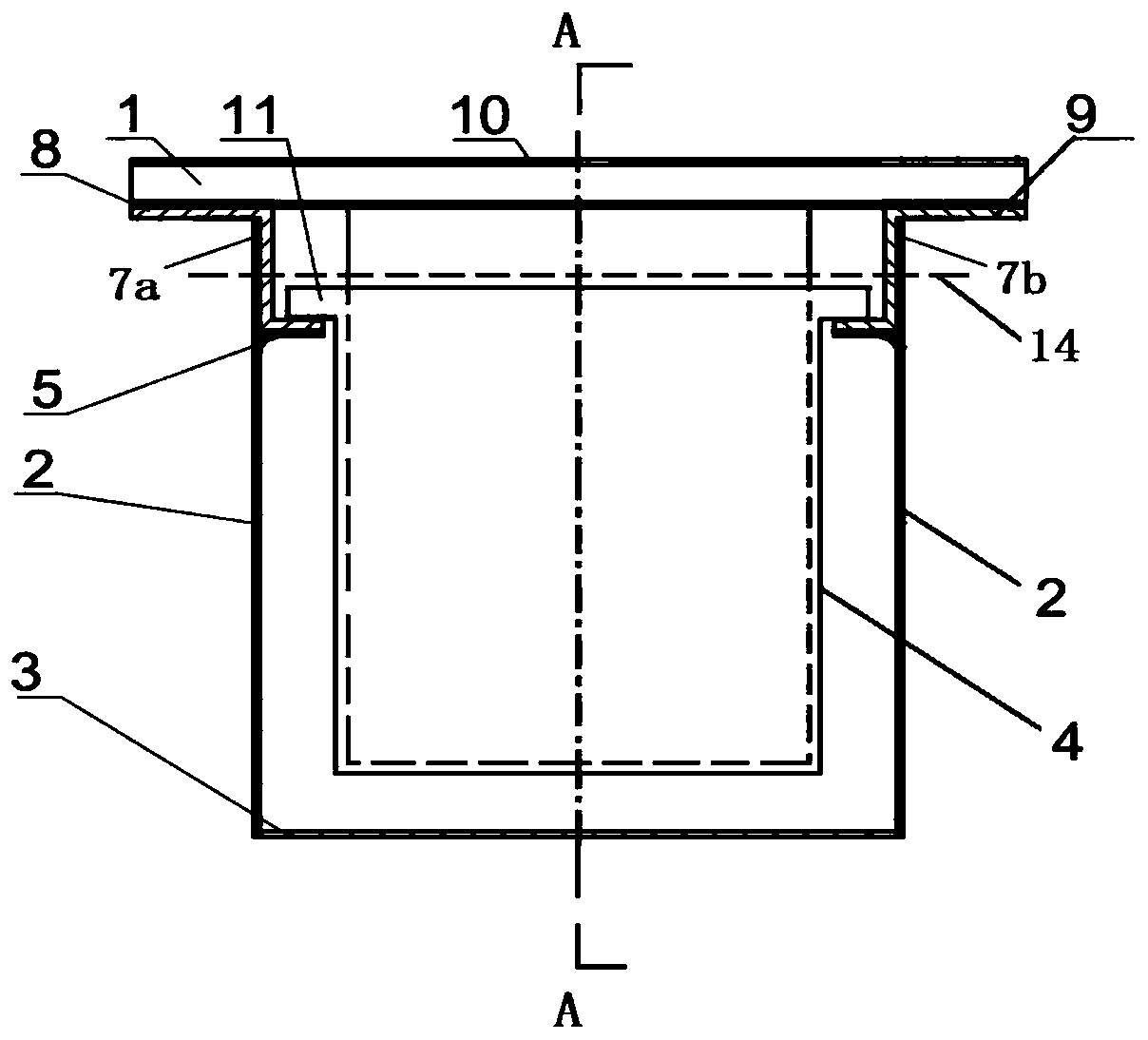

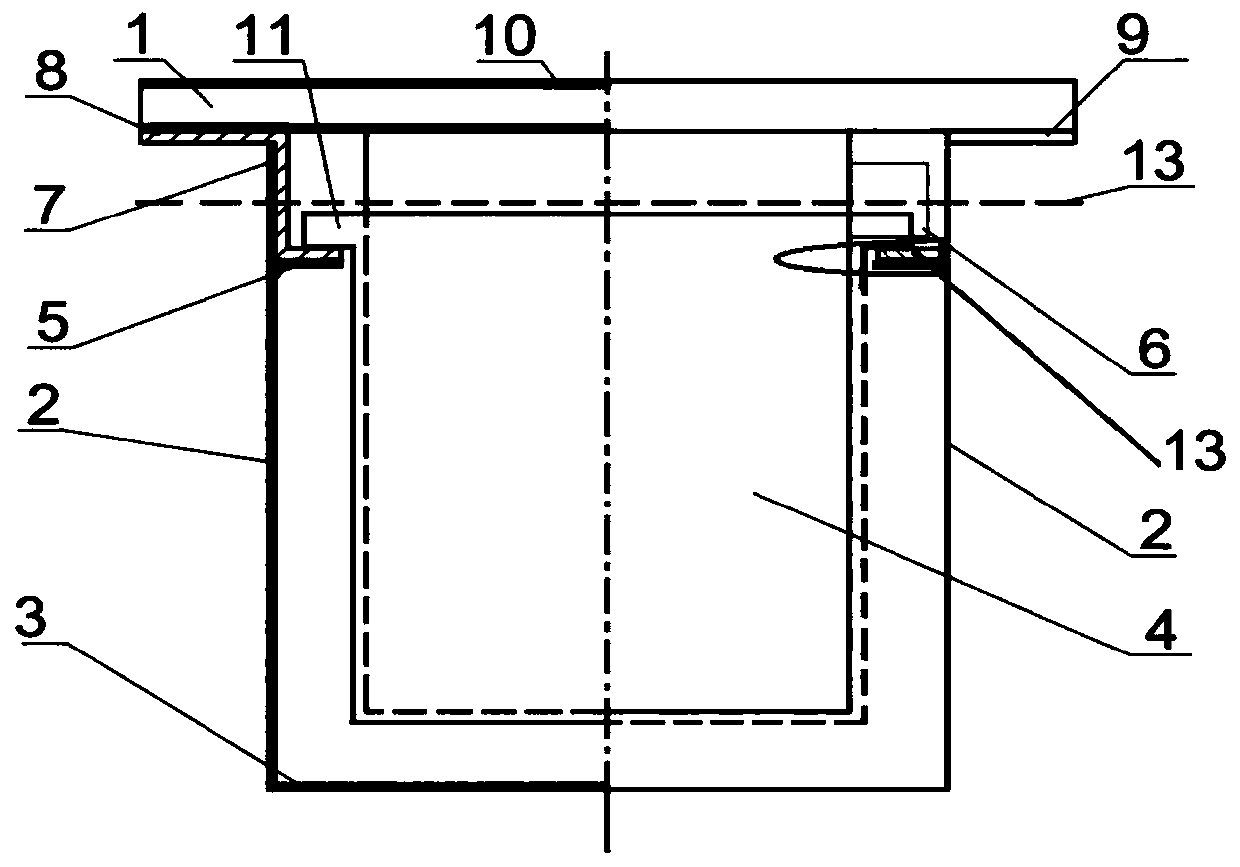

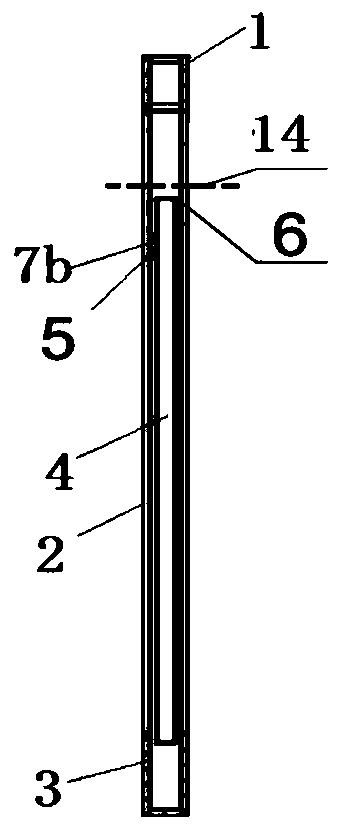

[0062] The present invention will be further described below with reference to the drawings and embodiments, but the content of the present invention is not limited to the scope described.

[0063] Such as Figure 1-Figure 5 As shown, the fabricated anode for electrochemical synthesis of stannous octoate salt is assembled with a tin anode plate 4 in a support frame. The supporting frame includes a square tube conductive beam 1, a frame composed of vertical frames 2 on both sides and a bottom horizontal frame 3 welded under the conductive beam, and an insulating layer is sprayed on the outer surface of the frame, and the frame is notched inward U-shaped groove frame; the upper groove bottom of the two U-shaped groove mullions are welded with lug supports 5. A conductive copper bar 8 is welded or riveted on the bottom surface of one side of the conductive beam 1, and an insulating plate 9 is welded or riveted or covered on the bottom surface of the other side of the conductive bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com