A composite floor based on heating integration

A composite floor and movable panel technology, applied in heating methods, lighting and heating equipment, space heating and ventilation, etc., can solve problems such as slow heat transfer, easy delamination, and loosening of composite floor layers and layers, and achieve reduction Heat loss rate, full protection of laminate flooring, fastening and tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

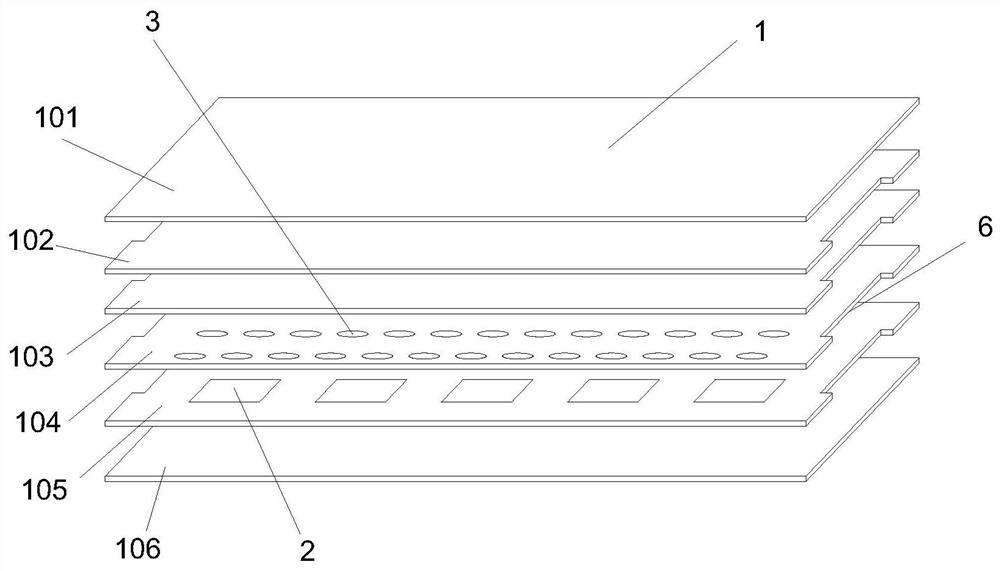

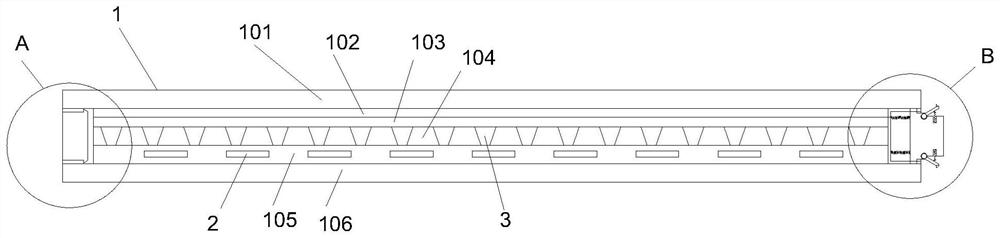

[0025] See Figure 1-5The present invention provides a technical solution: a composite floor based on heating, including a composite floor 1, a composite floor 1 by a solid wood layer 101, a transfer layer 102, a dry layer 103, a thermally conductive layer 104, a heating layer 105, and a bottom The insulation layer 106 is composed, and the solid wood layer 101 is located at the topmost layer, and the transfer layer 102 is located under the solid wood layer 101, and the transfer layer 102 is fixedly adhered to the solid wood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com