Tunnel second lining remediation method for die cast construction of lining

A tunnel and lining technology, which is applied in the field of tunnel secondary lining renovation and construction, can solve the problems of failure to remediate tunnel secondary lining diseases, the quality of lining cannot be guaranteed, and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

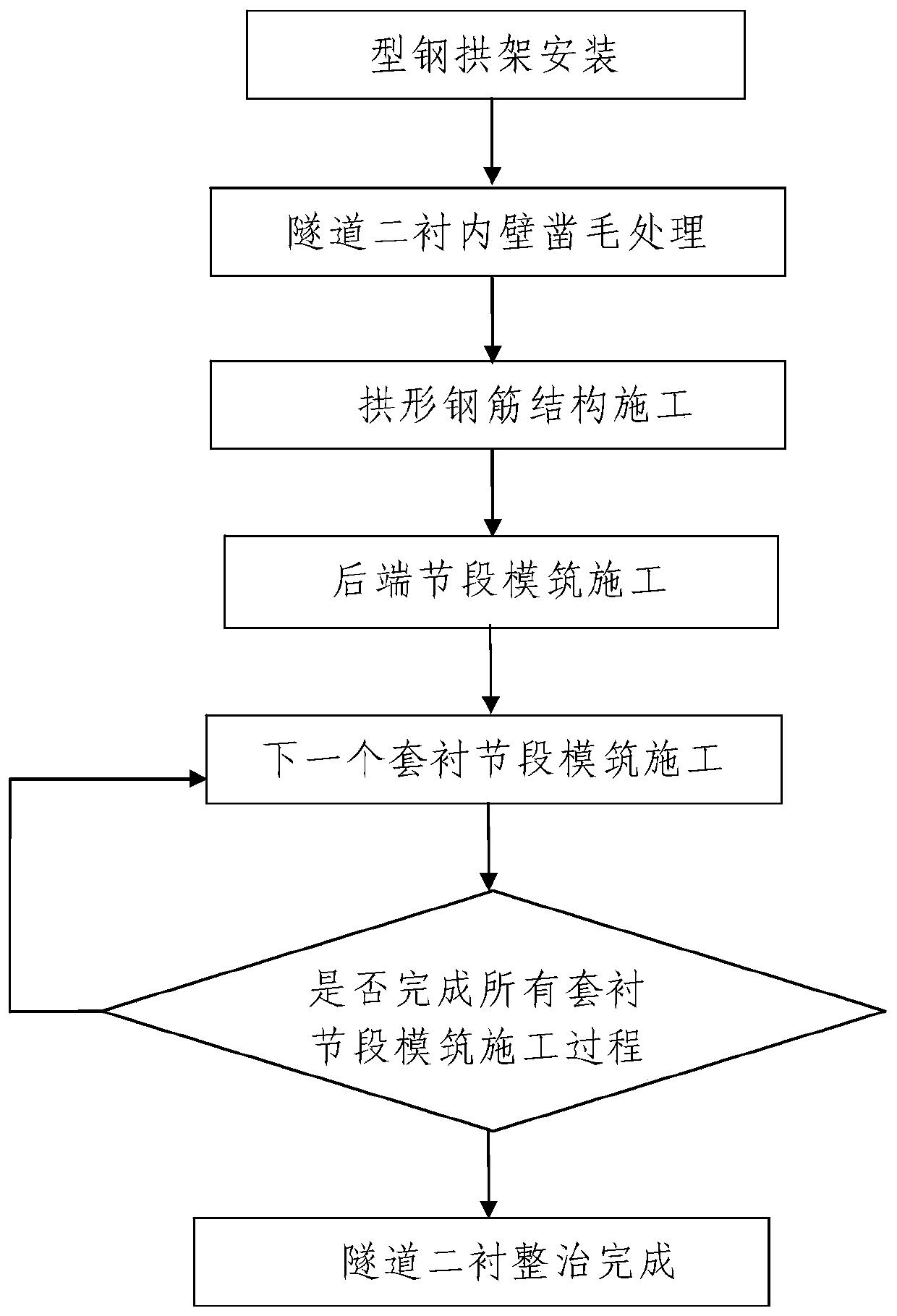

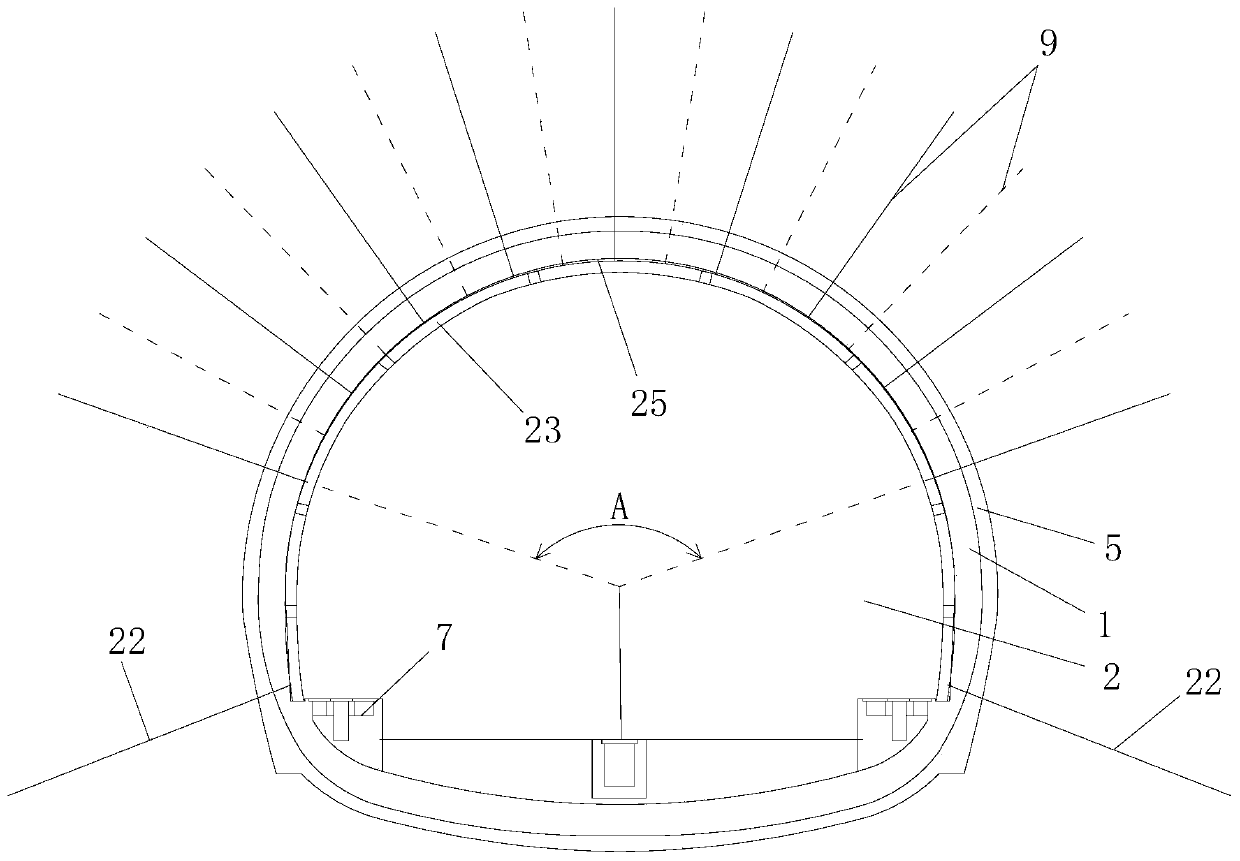

[0113] Such as figure 1 The method for the secondary lining renovation of a tunnel in the formwork construction of the lining is shown. The reinforced lining 24 is used to reinforce the secondary lining 1 of the tunnel section 2 that needs to be renovated. The tunnel section 2 to be renovated is a tunnel that passes through the karst stratum Tunnel section and its excavation section is greater than 100m 2 , see figure 2 ;

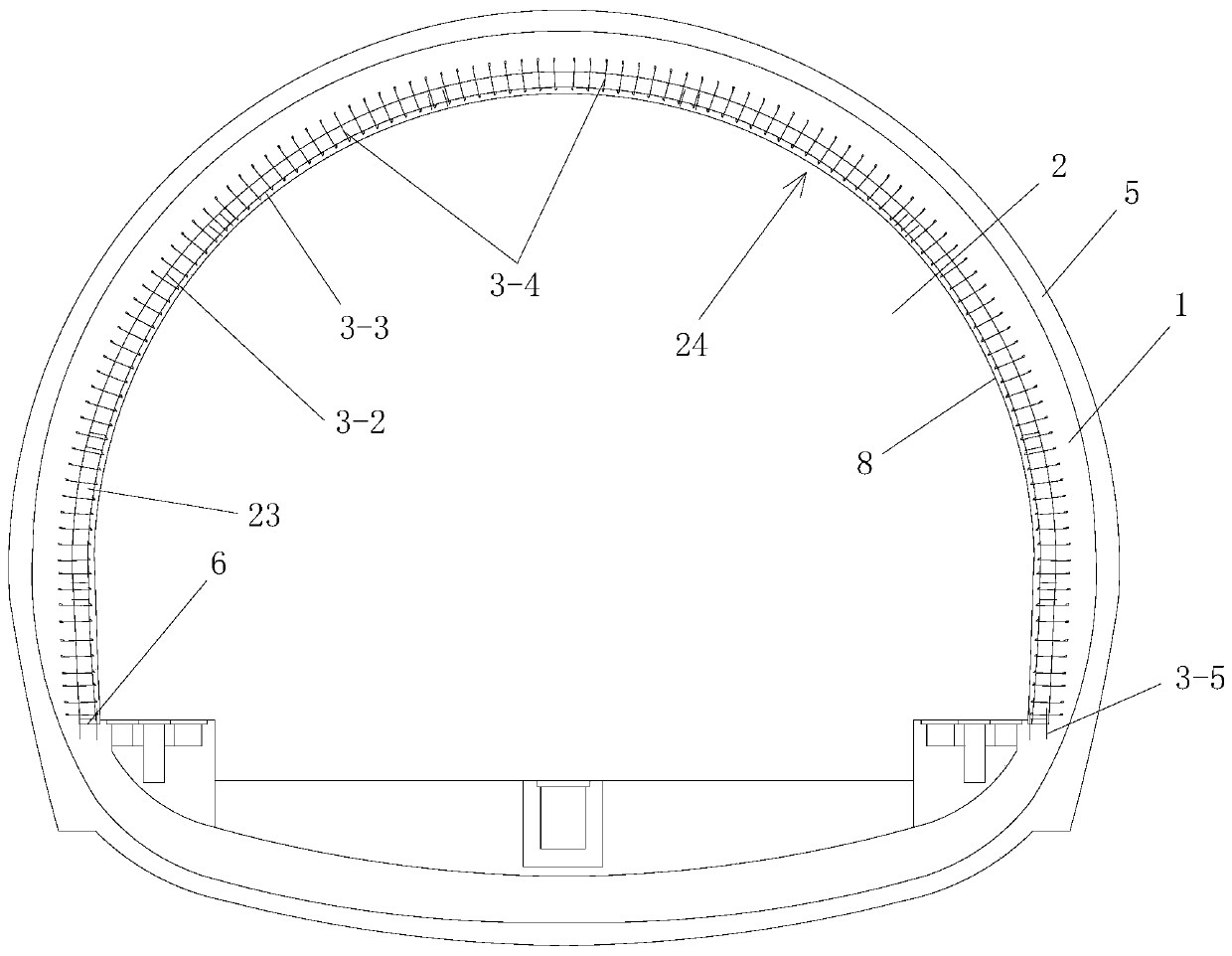

[0114] to combine image 3 , the reinforcing bushing 24 is laid on the inner side of the tunnel secondary lining 1; the tunnel secondary lining 1 is a full-section support structure for the full-section support of the tunnel section 2 to be renovated, and the tunnel secondary lining 1 is Reinforced concrete lining; the secondary lining of the tunnel 1 includes the secondary lining of the arch wall supporting the arch wall of the tunnel section 2 to be repaired and the tunnel inverted arch arranged at the bottom of the tunnel section 2 to be repaired, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com